Annular multilayer sleeve membrane reactor and method for producing methyl propiolate through same

A multi-layer casing and membrane reactor technology, which is applied in chemical instruments and methods, preparation of carboxylic acid esters, preparation of organic compounds, etc., can solve the problem of uneven distribution of air for inhibiting polymerization, low conversion rate of esterification reaction, and catalyst utilization. Low efficiency and other problems, to achieve the effect of improving conversion rate and selectivity, reducing corrosion, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

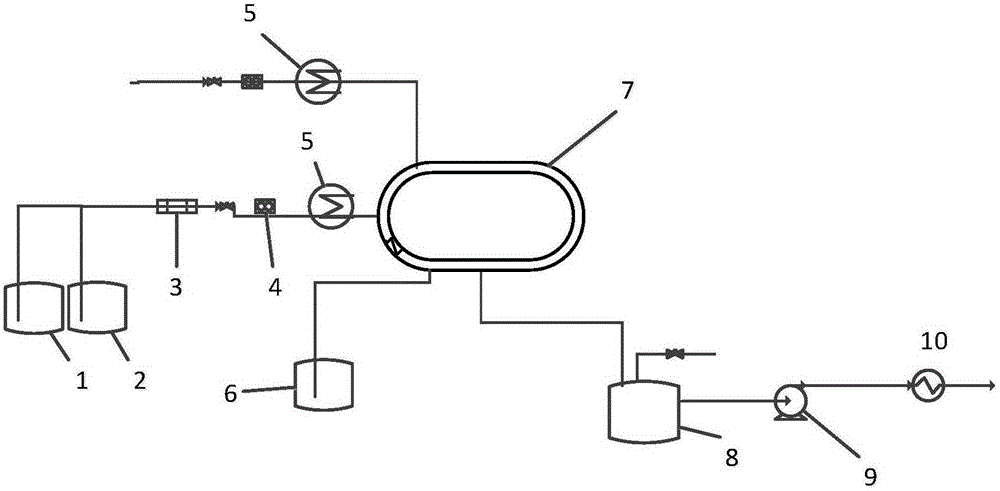

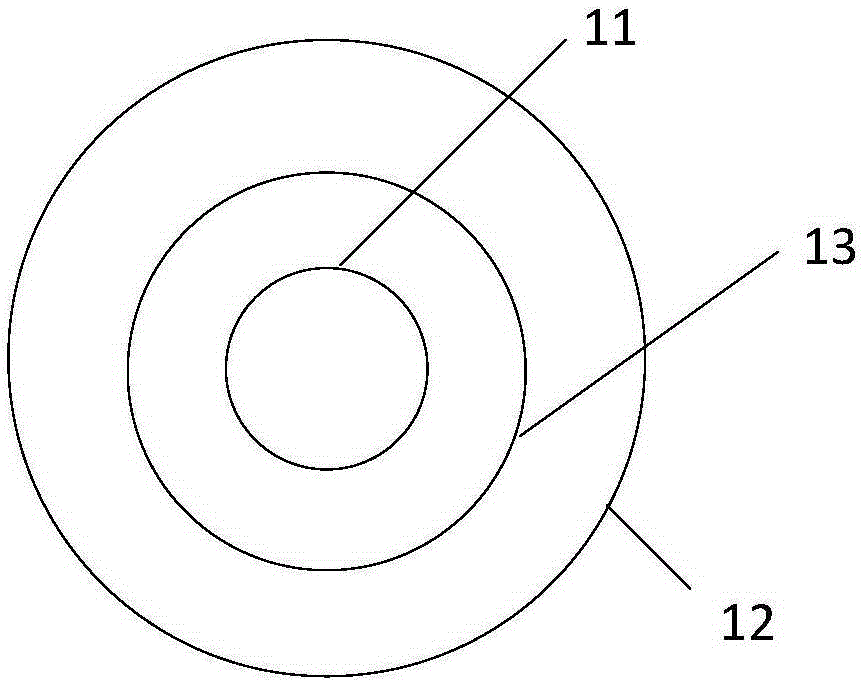

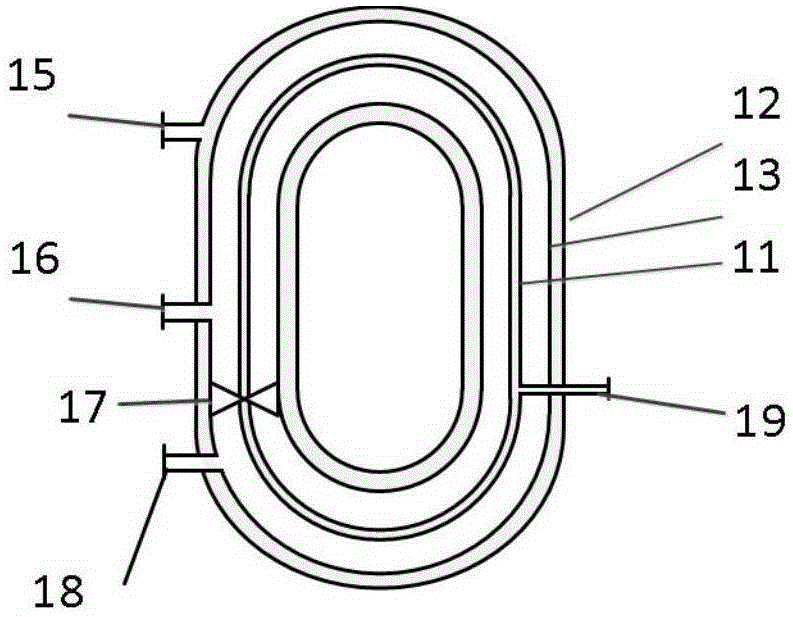

[0037] The esterification reaction of acrylic acid and methanol is carried out by using the annular multi-layer sleeve reactor provided by the invention to generate methyl acrylate. The reactor 7 is placed horizontally, the length of the radial section is 0.92m, and the diameters of the three-layer casing are 0.1m, 0.48m, and 0.6m from the inside to the outside. The Amberlyst25wet cationic resin catalyst produced by Dow Chemical is circulated inside the middle membrane sleeve 13, and the mass space velocity of acrylic acid is 3.65h -1 . Mix acrylic acid and methanol with a molar ratio of 1.12:1 uniformly through the static mixer 3, transport them to the preheater 5 at a speed of 10kg / h through the raw material pump to preheat to 75°C, and then enter the middle membrane casing 13 of the reactor 7 Inside. The inner pressure of the inner membrane casing 11 is 30KPa, the inner pressure of the middle membrane casing 13 is 300KPa, and the outer casing 12 is fed with air preheated ...

Embodiment 2

[0041] The esterification reaction of acrylic acid and ethanol is carried out by using the annular multi-layer sleeve reactor provided by the invention to generate ethyl acrylate. The reactor 7 is placed horizontally, the length of the radial section is 0.92m, and the diameters of the three-layer casing are 0.1m, 0.6m, and 1m from the inside to the outside. Amberlyst25wet cationic resin catalyst circulates inside the membrane sleeve 13, and the mass space velocity of acrylic acid is 3.65h -1 . Mix acrylic acid and ethanol with a molar ratio of 1.10:1 uniformly through the static mixer 3, transport them to the preheater 5 at a speed of 10kg / h through the raw material pump to preheat to 80°C, and then enter the middle film jacket 13 tube of the reactor 7 . The inner pressure of the inner membrane casing 11 is 40KPa, the inner pressure of the middle membrane casing 13 is 150KPa, and the outer casing 12 is fed with air preheated to 80°C with a pressure of 160kPa. The residence ...

Embodiment 3

[0045] The esterification reaction of acrylic acid and n-butanol is carried out by using the annular multi-layer sleeve reactor provided by the invention to generate butyl acrylate. The reactor 7 is placed horizontally, the length of the radial section is 0.92m, and the diameters of the three-layer casing are 0.1m, 0.3m, and 0.7m from the inside to the outside. The Amberlyst39wet cationic resin catalyst produced by Dow is circulated inside the middle membrane sleeve 13, and the mass space velocity of acrylic acid is 3.65h -1 . Mix acrylic acid and butanol with a molar ratio of 1:1.20 uniformly through the static mixer 3, transport them to the preheater 5 through the raw material pump at a speed of 10kg / h, preheat to 95°C, and then enter the middle membrane in the reactor 7 Inside the casing 13. The inner pressure of the inner membrane casing 11 is 20KPa, the inner pressure of the middle membrane casing 13 is 350KPa, and the outer casing is fed with air preheated to 95°C with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com