A composite hydrolysis acidification reactor and process

An acidification reactor and composite hydrolysis technology, applied in chemical instruments and methods, aerobic and anaerobic treatment, anaerobic digestion treatment, etc., can solve the problem of high proportion of toxic and harmful substances and refractory organic matter, poor hydrolysis and acidification effect To achieve the effect of improving the utilization rate of pool capacity, avoiding hydraulic short flow, and evenly distributing water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Using the invention to treat chemical waste water mainly producing petrochemical cascade products, the water volume is 900m 3 / d, the influent water quality is as follows: COD Cr 3500mg / L, BOD 5 716mg / L, ammonia nitrogen 25mg / L, pH 7.8, and salt content of 1.1%.

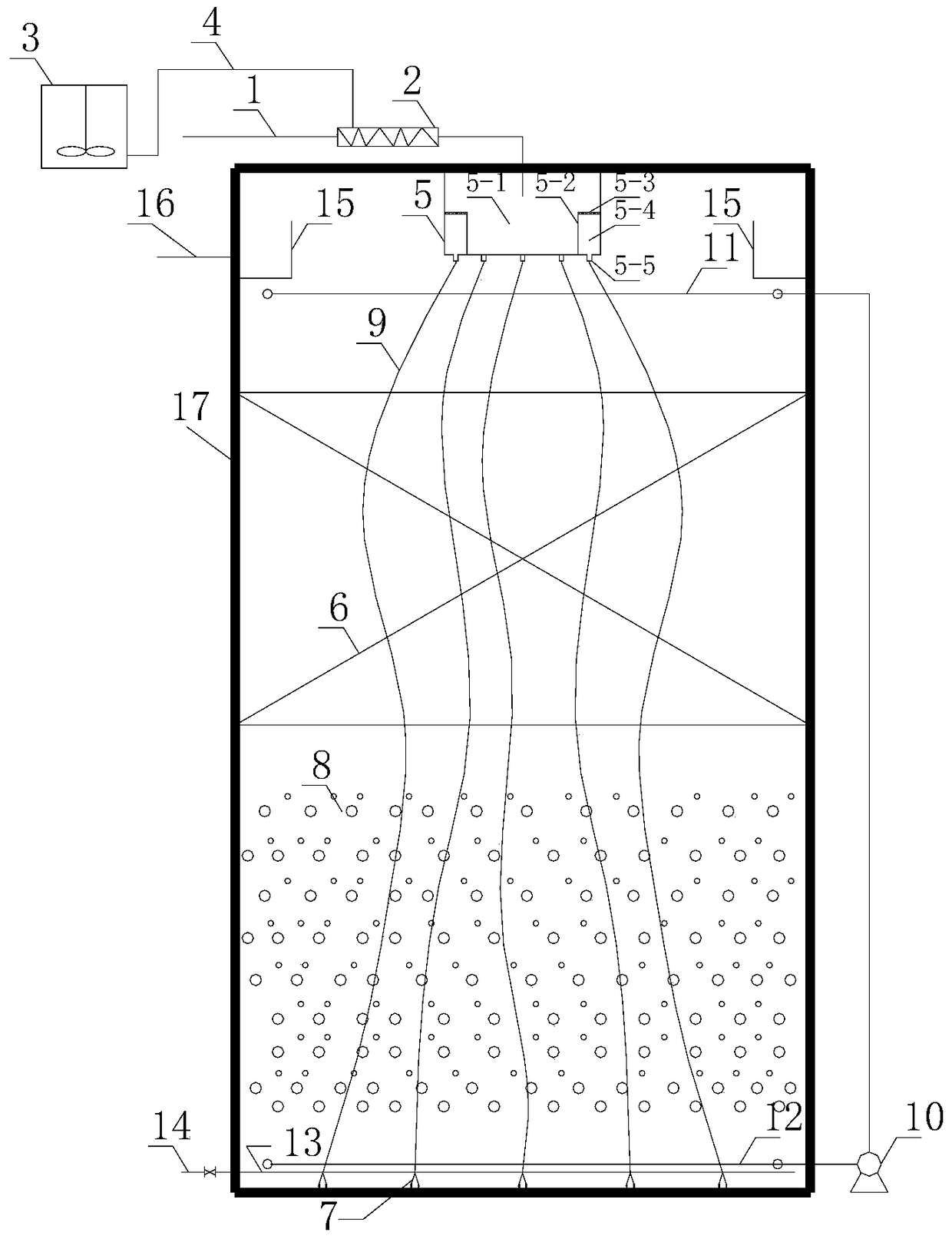

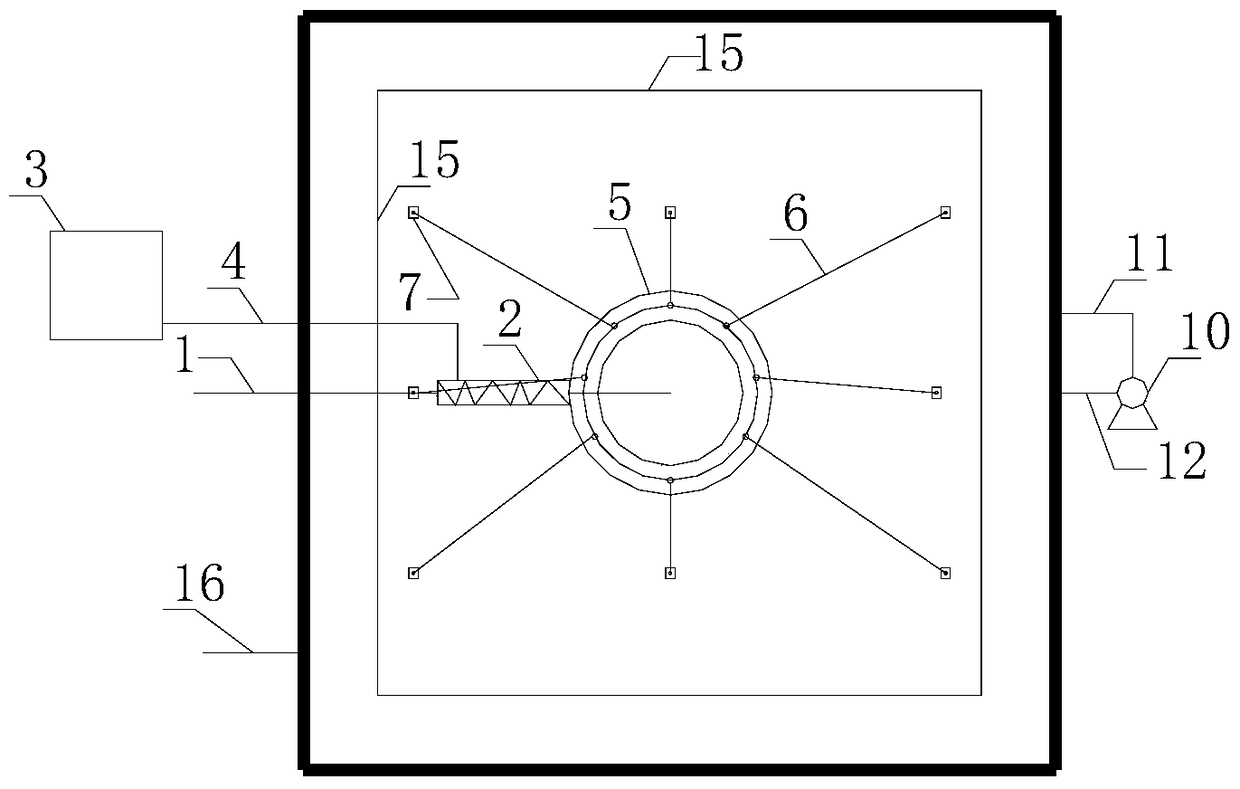

[0071] The wastewater is first uniformly entered into the water inlet pipe set at the top of the hydrolysis and acidification tank from the regulating tank, and the high-efficiency microbial expansion device is added to the pipeline mixer through the dosing pipeline; the sewage and the high-efficiency microbial inoculum are evenly mixed and flow into two point-to-point water distribution. The high-efficiency microbial inoculum is dosed intermittently, generally once a week, and the dose is 0.2‰ of the treated water. The sewage is distributed into 24 equal volumes of water through a point-to-point water distributor, and is transported to 24 water distribution points evenly arranged at the bottom of the pool t...

Embodiment 2

[0075] Using the invention to treat printing and dyeing wastewater, the water volume is 2200m 3 / d, the influent water quality is as follows: COD Cr 1325mg / L, BOD 5 291mg / L, ammonia nitrogen 7mg / L, chroma 512 times, pH 9.2.

[0076] The wastewater first enters the top of the hydrolysis tank, and the high-efficiency microbial expansion device is added to the pipeline mixer through the dosing pipeline; the sewage and the high-efficiency microbial inoculum are evenly mixed and then flow into four point-to-point water distributors; Dosing intermittently, generally once a week, and the dosage is 0.1‰ of the treated water. The sewage is distributed into 24 equal volumes of water through a point-to-point water distributor, and is transported to 24 water distribution points evenly arranged at the bottom of the pool through a φ50 water distribution hose. The sewage rises evenly from the bottom of the hydrolysis tank with a rising flow rate of 1.2m / h. During the rising process of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com