A method of using modified steel slag to promote acid production by anaerobic fermentation of excess sludge

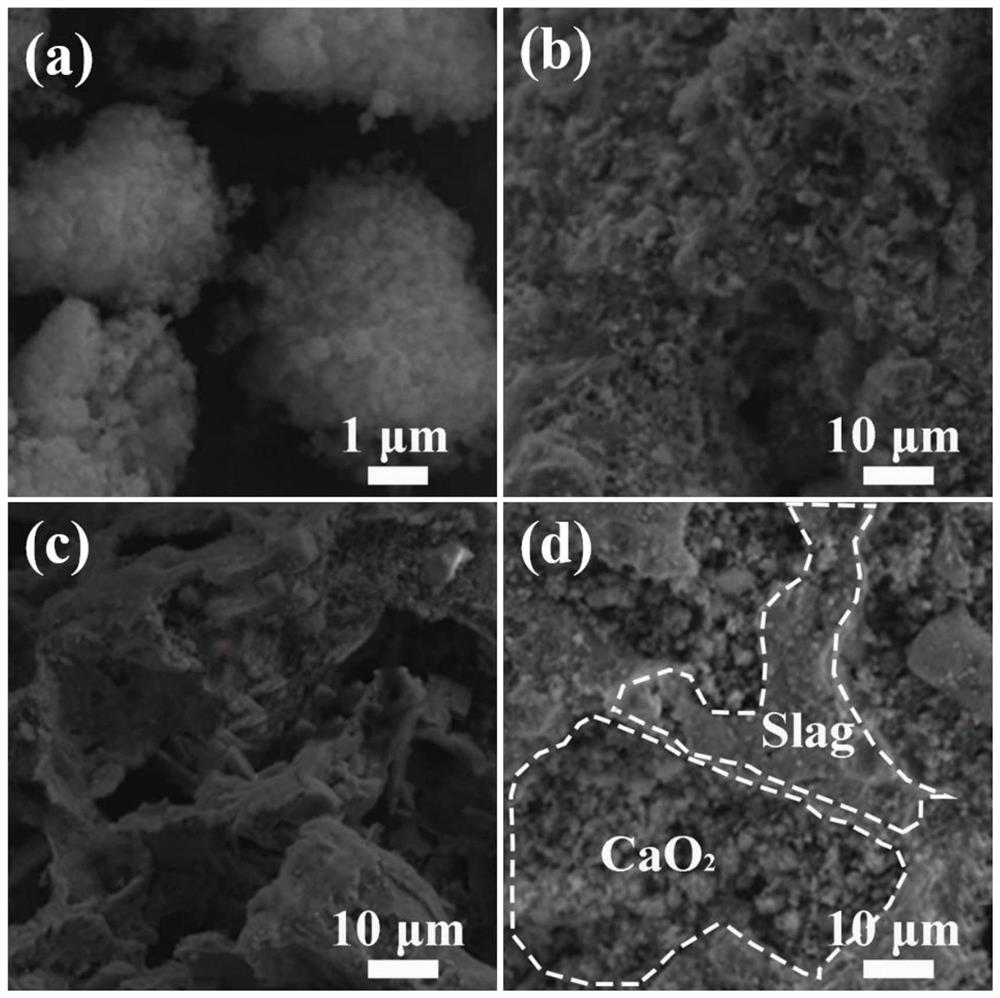

A technology of excess sludge and anaerobic fermentation, applied in fermentation, biological sludge treatment, chemical instruments and methods, etc., can solve the problem of low acid production efficiency of sludge anaerobic fermentation, and achieve the promotion of hydrolysis and acidification process, obvious porous structure, the effect of reducing the particle size of sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

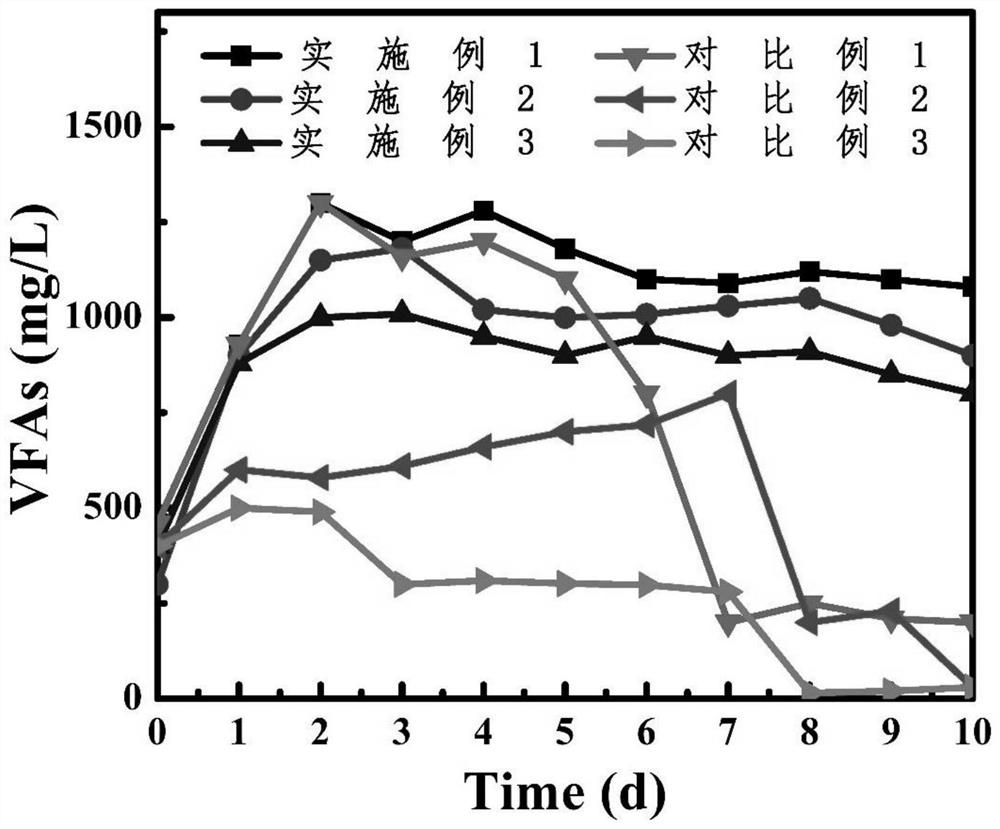

Embodiment 1

[0031] (1) Preparation of nano calcium peroxide powder:

[0032] Dissolve 2g of calcium chloride in 30mL of distilled water, add 15mL of ammonia water (the concentration of ammonia water used is 2mol / L) and 150mL of polyethylene glycol under magnetic stirring conditions (400rpm), and then add 150mL of polyethylene glycol to the mixture at a rate of 4 drops per minute. 15 mL of H was added dropwise to the solution 2 o 2 solution (the H used in it 2 o 2 Solution concentration is 30%), after stirring for 4 hours, calcium peroxide solution was obtained. Subsequently, adding pH to the calcium peroxide solution is a NaOH solution of 13, and when the pH of the calcium peroxide solution reaches 11, the precipitate is collected by centrifugation, and the centrifugal speed is 6000 rpm, and then it is washed three times with a pH of 13 NaOH solution, and washed twice with distilled water. The product was collected by centrifugation. The product was dried in a vacuum oven at 70° C. f...

Embodiment 2

[0040] (1) Preparation of nano calcium peroxide powder:

[0041] Dissolve 1 g of calcium chloride in 20 mL of distilled water, and add 10 mL of ammonia water (the concentration of ammonia water used is 1 mol / L) and 100 mL of polyethylene glycol under magnetic stirring conditions (300 rpm). Then, 10 mL of H was added dropwise to the mixed solution at a rate of 3 drops per minute 2 o 2 solution, where the H 2 o 2 The concentration of the solution was 20%, and after stirring for 2 hours, a calcium peroxide solution was obtained. Subsequently, NaOH solution with a pH of 12 was added to the calcium peroxide solution, and when the pH of the calcium peroxide solution reached 11, the precipitate was collected by centrifugation at a centrifugation rate of 5000 rpm. After that, it was washed three times with NaOH solution having a pH of 13 and twice with distilled water, and the product was collected by centrifugation. The product was dried in a vacuum oven at 60° C. for 2 h to obt...

Embodiment 3

[0049] (1) Preparation of nano calcium peroxide powder:

[0050] Dissolve 4 g of calcium chloride in 50 mL of distilled water, and add 20 mL of ammonia water (the concentration of ammonia water used is 3 mol / L) and 200 mL of polyethylene glycol under magnetic stirring conditions (500 rpm). Then, 20 mL of H was added dropwise to the mixed solution at a rate of 5 drops per minute 2 o 2 solution (the H used in it 2 o 2 The solution concentration is 50%). After stirring for 5 hours, a calcium peroxide solution was obtained. Subsequently, a NaOH solution with a pH of 13 was added to the calcium peroxide solution, and when the pH of the calcium peroxide solution reached 12, the precipitate was collected by centrifugation at a centrifugation rate of 8000 rpm. After that, it was washed three times with NaOH solution having a pH of 13 and twice with distilled water, and the product was collected by centrifugation. The product was dried in a vacuum oven at 80° C. for 4 h to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com