Method of preparing aromatic aldehyde and ketone through continuously oxidizing aromatic alcohol by adopting tubular reactor

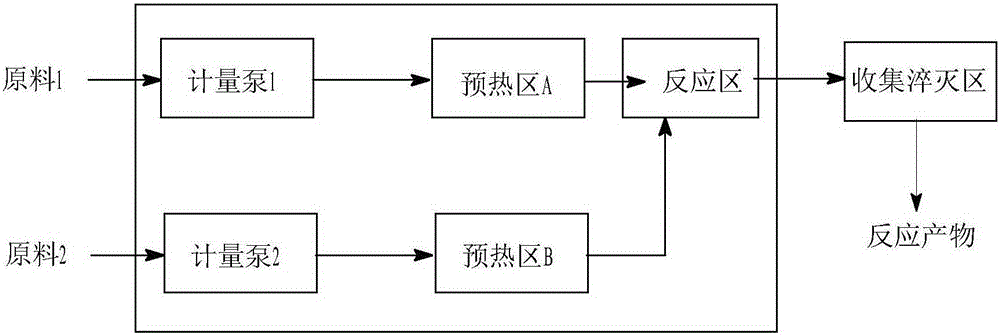

A tubular reactor, the technology of aromatic aldehydes and ketones, applied in the oxidation preparation of carbonyl compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve the problem of target product selectivity, low yield, low utilization rate of oxidant, mass transfer problems such as poor heat transfer effect, to achieve the effect of improving the reaction rate and the utilization rate of raw materials, avoiding the use of co-catalysts, and shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

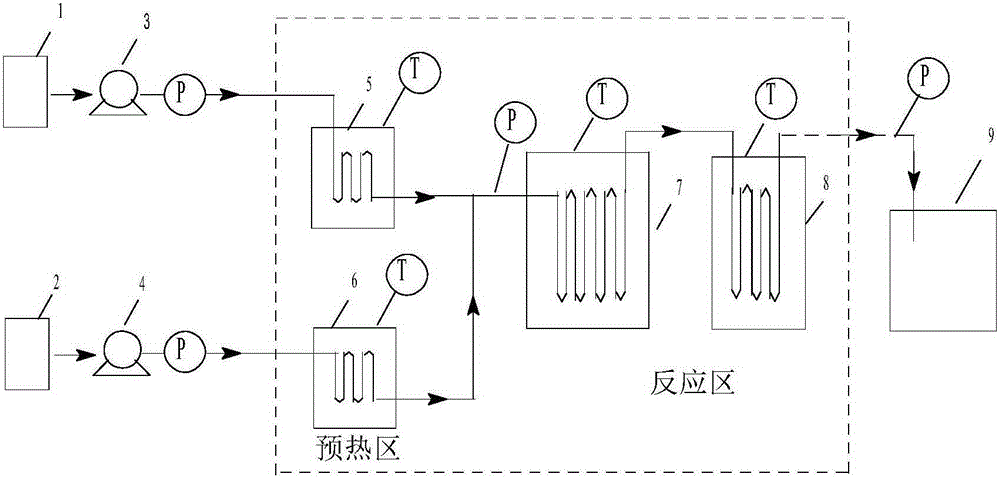

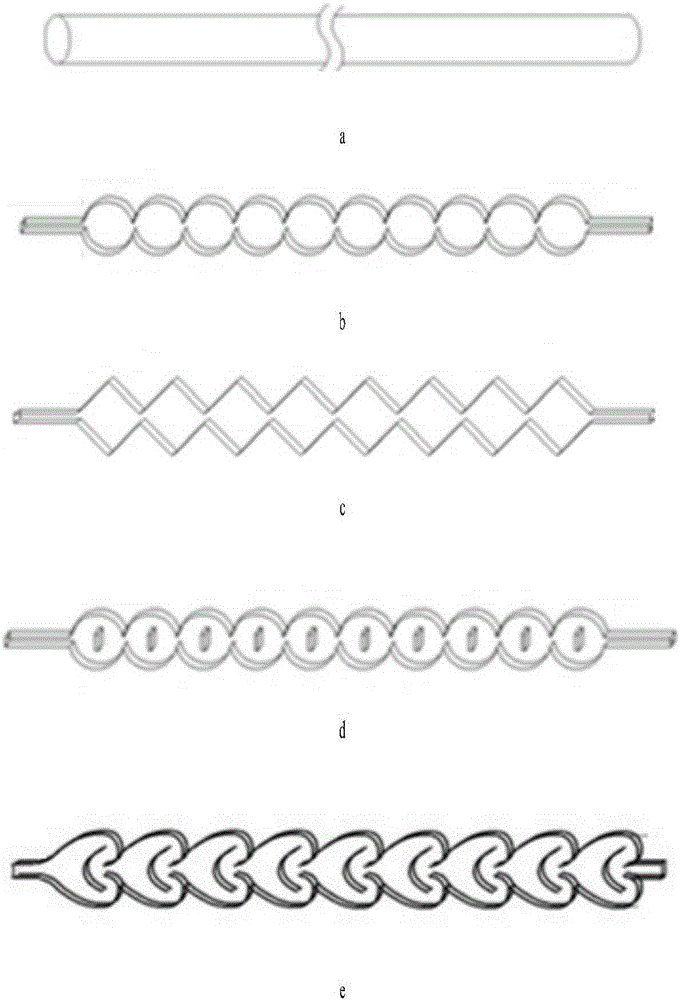

[0035] (1) Device: refer to figure 2 Determine the connection mode of the tubular reactor, the type of pipeline is: (3a) PFA circular tube channel, the length of the pipeline is determined according to the flow rate and reaction residence time, and the heat exchange medium is heat transfer oil or water.

[0036] (2) Stir and mix the substrate p-methoxybenzyl alcohol and the solvent evenly, adjust the mixed solution of the catalyst and sodium hypochlorite to the required pH value, and input them into raw material tanks 1 and 2 respectively. Then the two streams of materials are pumped into the tubular reactor through metering pumps 3 and 4, first preheated by preheating zones 5 and 6, and then enter the reaction zone for mixed reaction. The preheating temperature and reaction temperature of the reaction system were set at -10°C. Among them, the molar ratio of 2,2,6,6-tetramethylpiperidine-nitrogen-oxide (TEMPO) or supported TEMPO catalyst to p-methoxybenzyl alcohol is 0.005:1...

Embodiment 2

[0038] (1) Device: refer to figure 2 Determine the connection mode of the tubular reactor. The pipeline type is: (3a+3b) direct flow channel + round cake pulse variable diameter rectangular flat pipeline. The length of the pipeline is determined according to the flow rate and reaction residence time. The heat exchange medium is heat transfer oil or water.

[0039] (2) Stir and mix the substrate p-fluorobenzyl alcohol and the solvent evenly, adjust the mixed solution of the catalyst and sodium hypochlorite to the required pH value, and input them into raw material tanks 1 and 2 respectively. Then the two streams of materials are pumped into the tubular reactor through metering pumps 3 and 4, first preheated by preheating zones 5 and 6, and then enter the reaction zone for mixed reaction. The preheating temperature and reaction temperature of the reaction system were set at 0°C. Among them, the molar ratio of 2,2,6,6-tetramethylpiperidine-nitrogen-oxide (TEMPO) or supported T...

Embodiment 3

[0041] (1) Device: refer to figure 2 Determine the connection mode of the tubular reactor. The pipeline type is: (3a+3c) direct flow channel + oblique square cake pulse variable diameter rectangular flat pipeline. The length of the pipeline is determined according to the flow rate and reaction residence time. The heat transfer medium is heat transfer oil. or water.

[0042] (2) Stir and mix the substrate o-chlorobenzyl alcohol and the solvent evenly, adjust the mixed solution of the catalyst and sodium hypochlorite to the required pH value, and input them into raw material tanks 1 and 2 respectively. Then the two streams of materials are pumped into the tubular reactor through metering pumps 3 and 4, first preheated by preheating zones 5 and 6, and then enter the reaction zone for mixed reaction. The preheating temperature and reaction temperature of the reaction system were set at 25°C. Among them, the molar ratio of 2,2,6,6-tetramethylpiperidine-nitrogen-oxide (TEMPO) or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com