Polylactic acid stereo complex magnetic nanometer vesicle preparation method

A technology of stereocomplex and magnetic nanotechnology, which is applied in the fields of polymer materials and biomedical engineering, can solve the problems of poor stability of nanovesicles and easy leakage of loaded nanoparticles, and achieve the best stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

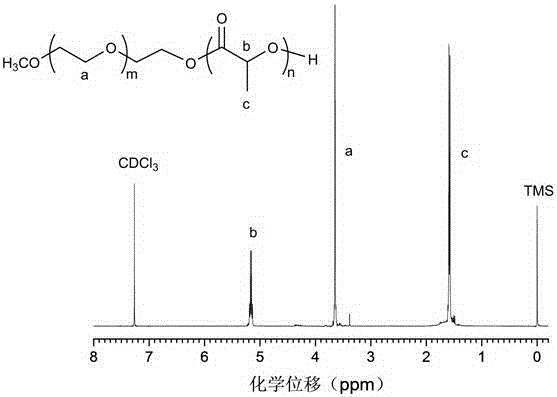

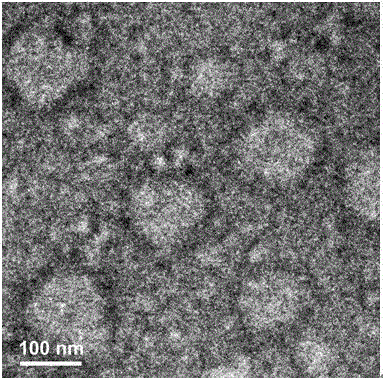

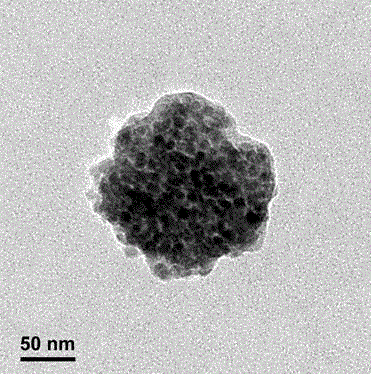

Embodiment 1

[0022] Take 0.2g of polyethylene glycol monomethyl ether with a molecular weight of 2000, 0.1g of L-lactide and 0.1mg of stannous octoate into a reaction bottle, protect with argon, react at 110°C for 12 hours, dissolve dichloromethane, and precipitate with ether 2 to 3 times, filter, and vacuum dry the filter cake to obtain L-polylactic acid-polyethylene glycol block copolymer; take 0.2g of polyethylene glycol monomethyl ether with a molecular weight of 2000, 0.1g of D-lactide and octanoic acid Put 0.2 mg of stannous into the reaction bottle, under argon protection, react at 105°C for 12 hours, dissolve in dichloromethane, precipitate with ether for 2 to 3 times, filter, and dry the filter cake in vacuum to obtain the D-polylactic acid-polyethylene glycol block Copolymer; Dissolve the product in dichloromethane respectively, and prepare 10mg / mL L-polylactic acid-polyethylene glycol block copolymer solution and D-polylactic acid-polyethylene glycol block copolymer solution. Th...

Embodiment 2

[0025] Take 0.2g of polyethylene glycol monomethyl ether with a molecular weight of 2000, 0.1g of L-lactide and 0.1mg of stannous octoate into a reaction bottle, protect with argon, react at 110°C for 12 hours, dissolve dichloromethane, and precipitate with ether 2 to 3 times, filter, and vacuum dry the filter cake to obtain L-polylactic acid-polyethylene glycol block copolymer; take 0.2g of polyethylene glycol monomethyl ether with a molecular weight of 2000, 0.1g of D-lactide and octanoic acid Put 0.2 mg of stannous into the reaction bottle, under argon protection, react at 105°C for 12 hours, dissolve in dichloromethane, precipitate with ether for 2 to 3 times, filter, and dry the filter cake in vacuum to obtain the D-polylactic acid-polyethylene glycol block Copolymer; Dissolve the product in dichloromethane respectively, and prepare 10mg / mL L-polylactic acid-polyethylene glycol block copolymer solution and D-polylactic acid-polyethylene glycol block copolymer solution. Th...

Embodiment 3

[0028]Take 0.25g of polyethylene glycol monomethyl ether with a molecular weight of 5000, 0.12g of L-lactide and 0.13mg of stannous octoate into a round bottom flask, protect it with argon, and react at 130°C for 24 hours, dissolve dichloromethane, diethyl ether Precipitate 2 to 3 times, filter, and vacuum-dry the filter cake to obtain L-polylactic acid-polyethylene glycol block copolymer; take 0.25g of polyethylene glycol monomethyl ether with a molecular weight of 5000, 0.12g of D-lactide and Put 0.13 mg of stannous octoate into a round-bottomed flask, protect it with argon, react at 130°C for 24 hours, dissolve in dichloromethane, precipitate with ether for 2 to 3 times, filter, and dry the filter cake in vacuum to obtain D-polylactic acid-polyethylene glycol Block copolymer; dissolve the product in dichloromethane respectively, and make 15mg / mL L-polylactic acid-polyethylene glycol block copolymer solution and D-polylactic acid-polyethylene glycol block copolymer solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com