Method of preparing phosphatidylserine

A technology of phosphatidylserine and serine, which is applied in the field of marine biology, can solve problems such as environmental pollution, flammable, explosive, toxic and harmful, and achieve the effects of ensuring reaction efficiency, improving production safety, and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

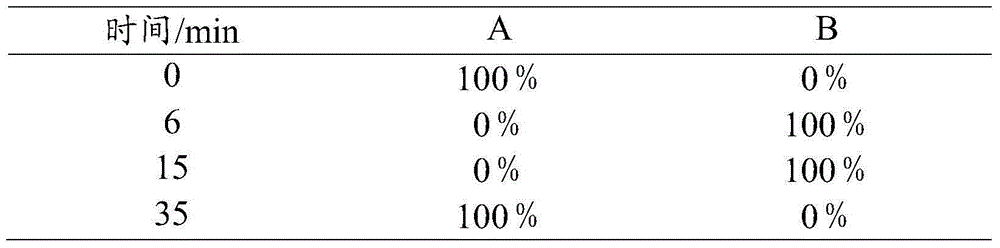

Method used

Image

Examples

Embodiment 1

[0056] Extracting 20g of phospholipid raw materials with a total phospholipid content of 40% from marine animal capry roe is dissolved in 40g ethyl octanoate to obtain solution A; 0.2g activity is 80U / mg powder phospholipase D, 30gL-serine is dissolved in 40g , acetic acid buffer solution with a pH value of 5.6 to obtain solution B; add the obtained solution A to the obtained solution B to obtain a mixed solution C, heat the obtained mixed solution C to 20°C and stir for 24 hours to obtain the reacted Solution D; after the reaction, the oil phase and the water phase of the solution D are separated by a centrifugation method, and the obtained oil phase part is completely or partially removed by a molecular distillation method, and the distillation temperature in the molecular distillation is 60 ℃, the distillation pressure is 0.1~1.0Pa, the feed rate is 2.5g / min, the speed of scraping film is 150rpm, and the molecular distillation heavy phase component is collected to obtain pho...

Embodiment 2

[0058] The 20g phospholipid raw material that extracts total phospholipid content from marine animal herring roe and is 70% is dissolved in 20g fish oil ethyl ester (DHA content is 17.96%), obtains solution A; 0.3g activity is 85U / mg powder phospholipase D, 35gL - Serine was dissolved in 120g of acetic acid buffer solution with a pH value of 6.0 to obtain solution B; the obtained solution A was added to the obtained solution B to obtain a mixed solution C, and the obtained mixed solution C was heated to 30°C and stirred for 20 hours , to obtain the solution D after the reaction; after the reaction, the solution D is centrifuged to separate the oil phase and the water phase, and the obtained oil phase is partially or completely removed by molecular distillation. The distillation temperature is 70°C, the distillation pressure is 1-5Pa, the feed rate is 2.5g / min, the speed of scraping film is 150rpm, and the heavy phase component of molecular distillation is collected to obtain ph...

Embodiment 3

[0060] Extract 2g phospholipid raw material that total phospholipid content is 50% from marine animal squid ovum and be dissolved in 20g ethyl oleate, obtain solution A; 1g activity is that 95U / mg powder phospholipase D, 2gL-serine are dissolved in 300g, PH In the acetic acid buffer solution with a value of 4.5, the solution B was obtained; the obtained solution A was added to the obtained solution B to obtain a mixed solution C, and the obtained mixed solution C was heated to 50°C and stirred for 8 hours to obtain the reacted solution D After the reaction, the solution D is centrifuged to separate the oil phase and the water phase, and the obtained oil phase is partially or partially removed by molecular distillation to remove medium and long-chain fatty acid ethyl esters. The distillation temperature in the molecular distillation is 90 ° C. The distillation pressure is 5-15Pa, the feed rate is 2.5g / min, the speed of scraping film is 150rpm, and the molecular distillation heav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com