Carbon-based nanoparticle film having anti-reflection micro-nanometer structure and preparation method

A micro-nano structure, carbon-based nano technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, to achieve uniform particle size, excellent infrared light detection performance, fine structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

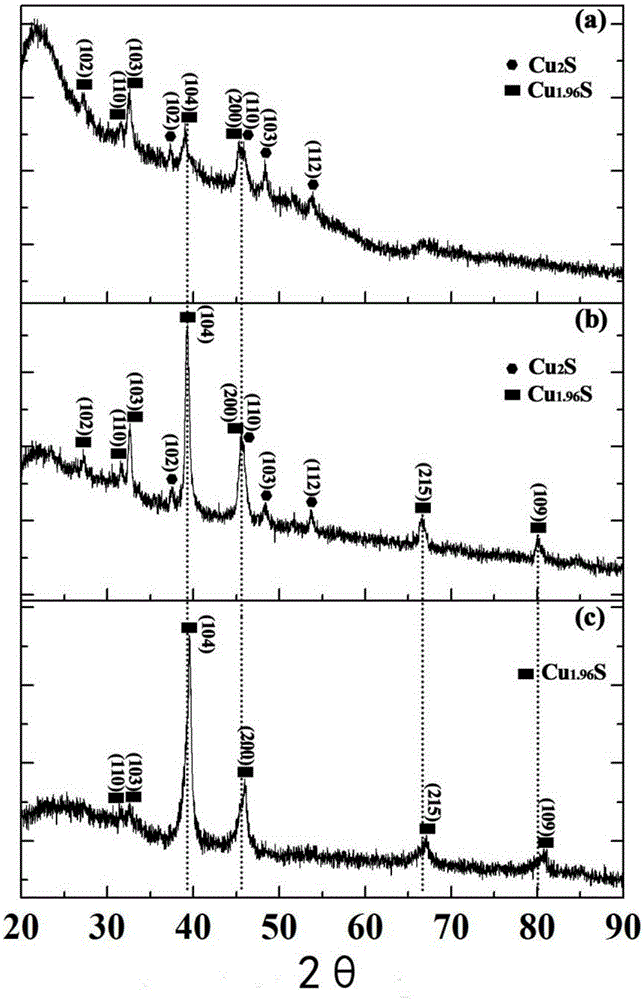

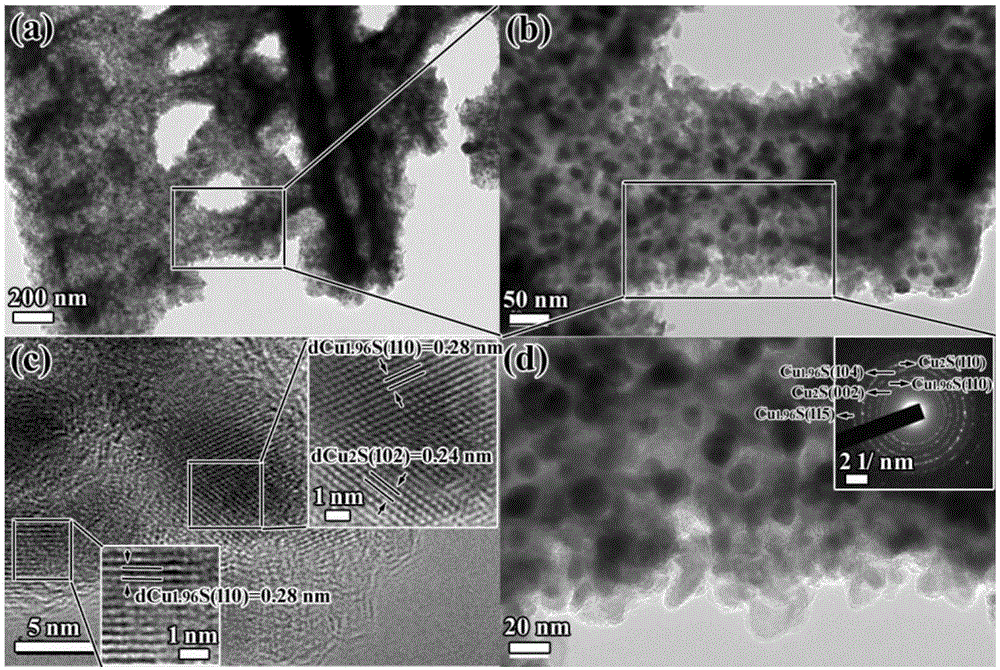

[0051] The composite solid-solution semiconductor coupled carbon-based nanoparticle film of this embodiment (marked as Cu 1.96 S-Cu 2 S@C_T_FW) preparation method, comprises the following steps:

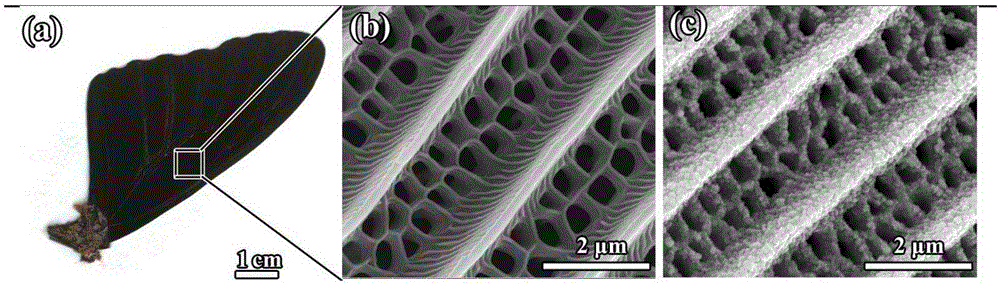

[0052] (1) Select the forewing of Papilionaceae as the black light-absorbing butterfly wing with anti-reflection microstructure;

[0053] (2) Carry out the following pretreatment and activation treatment to the forewings of the selected Papilionidae: first, the butterfly wings are soaked in absolute ethanol for 30 minutes, and then cleaned with deionized water; then the butterfly wings are immersed in a 15vol% volume fraction HNO 3 Put it in the solution for 2 hours, take it out and wash it; then soak the butterfly wings in 40% ethylenediamine absolute ethanol solution for 6 hours, then take it out, and wash it several times with deionized water; the above steps are used to remove pigments and impurities , and improve its surface adsorption properties;

[0054] (3) Deposition of ...

Embodiment 2

[0087] The carbon-based composite Cd of the present embodiment 2 The preparation method of S nanoparticle system, comprises the following steps:

[0088] (1) Select the forewing of Papilion butterfly as the butterfly wing with anti-reflection microstructure;

[0089] (2) Carry out the following pretreatment and activation treatment to the selected Papilio forewing: first put the butterfly wing in absolute ethanol to soak for 15min, and clean it with deionized water; then dip the butterfly wing in 5vol% HNO 3 Put it in the solution for 2 hours, take it out and wash it; then soak the butterfly wings in 10% ethylenediamine absolute ethanol solution for 6 hours, then take it out, and wash it several times with deionized water; the above steps are used to remove pigments and impurities , and improve its surface adsorption properties;

[0090] (3) Deposition of Au nanoparticles: immerse the activated butterfly wings in the chloroauric acid precursor solution at a constant tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com