Preparing method for high-solar-energy-absorption-rate and high-emissivity black matt film on surface of titanium alloy

A high-emissivity, titanium alloy technology, applied in the direction of surface reaction electrolytic coatings, coatings, electrolytic coatings, etc., can solve the problems of low bonding force between the film layer and the substrate, low emissivity, and low solar absorption rate, and achieve Excellent binding force and thermal stability, high absorption rate, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

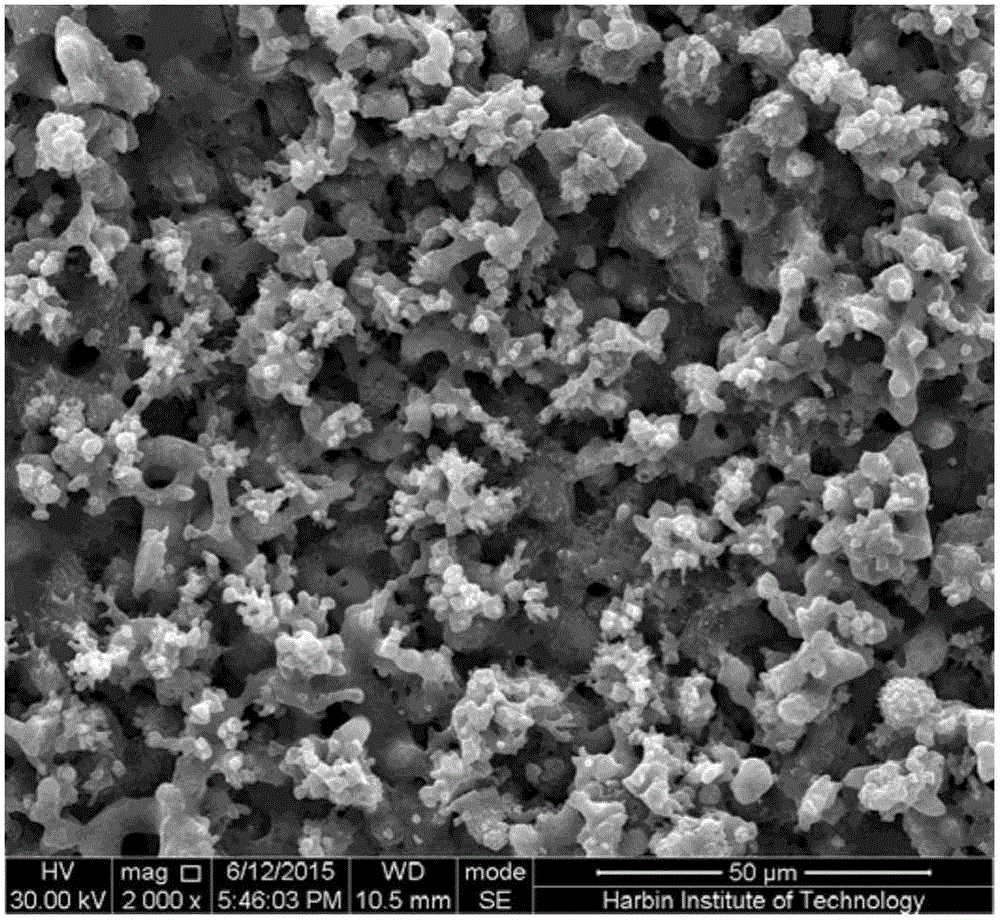

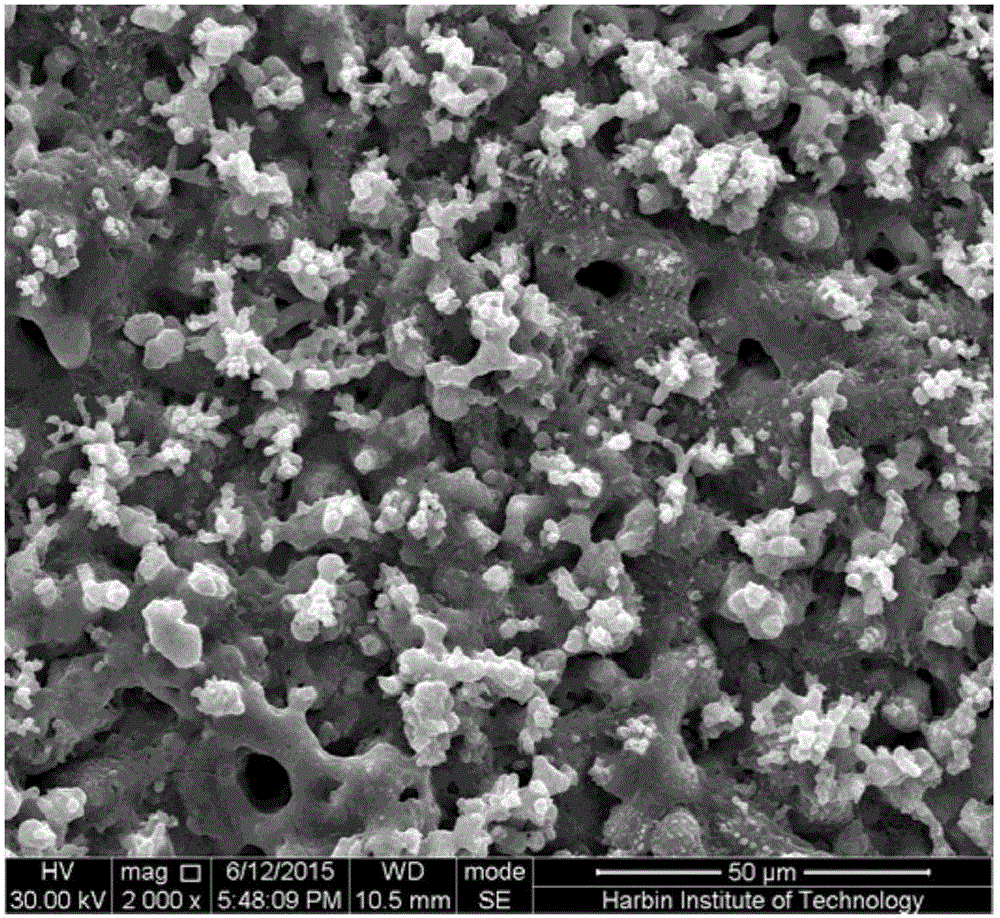

Image

Examples

specific Embodiment approach 2

[0036] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the film-forming agent described in step two is trisodium phosphate, sodium metasilicate, sodium polyphosphate, sodium hexametaphosphate, sodium tungstate , disodium edetate and ammonium metavanadate. Others are the same as the first embodiment.

specific Embodiment approach 3

[0037] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the additive described in step 2 is one of ferrous sulfate, nickel acetate and cobalt acetate or a mixture of several of them. Other steps are the same as those in Embodiment 1 or 2.

specific Embodiment approach 4

[0038]Embodiment 4: The difference between this embodiment and Embodiments 1 to 3 is that in step 2, the processed titanium alloy is placed in the electrolyte in stainless steel, and the processed titanium alloy is connected to the positive pole of the power supply. As the anode, the stainless steel electrolytic cell is connected to the negative pole of the power supply as the cathode; the pulse micro-arc oxidation power supply is used for power supply, at a constant voltage of 350V, a power frequency of 500Hz, a duty cycle of 30%, and an electrolyte temperature of 25°C and React for 10 minutes under the condition that the pH value of the electrolyte is 12, and obtain a black matte film layer with high solar energy absorption rate and high emissivity on the surface of the titanium alloy. Other steps are the same as those in Embodiments 1 to 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com