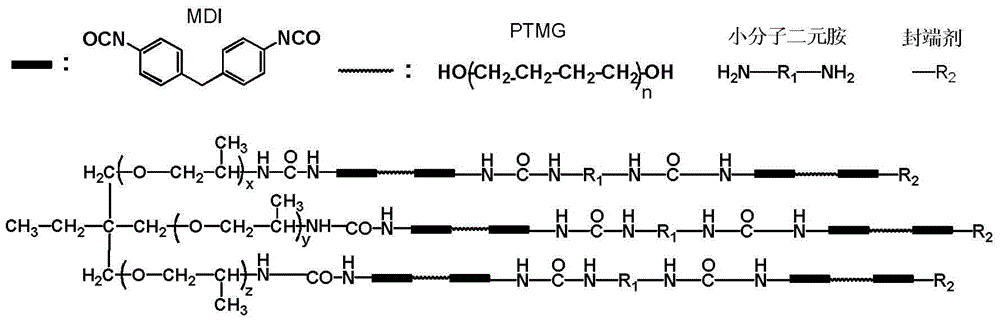

A kind of high concentration polyurethane urea spinning solution and preparation method thereof

A technology of polyurethane urea spinning and polyurethane urea, which is used in the preparation of spinning solutions, single-component synthetic polymer rayon, textiles and papermaking, etc., can solve the problems of branched entanglement and poor fluidity of branched polymers. , to achieve the effect of normal and stable process, stable and uniform properties, and small molecular size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

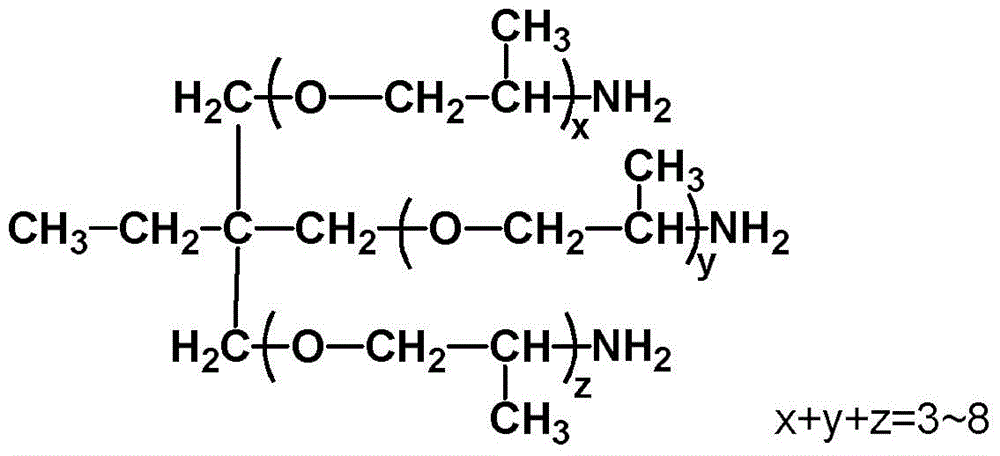

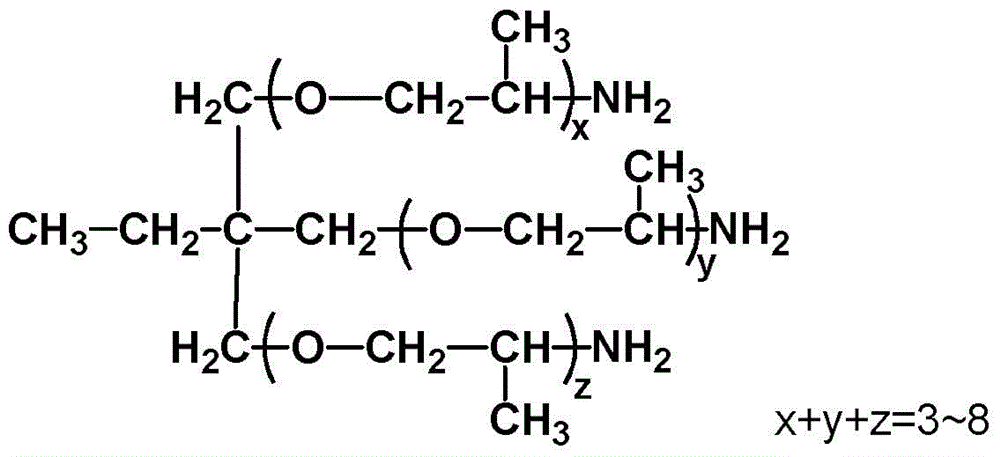

Method used

Image

Examples

Embodiment 1

[0045] 1. Add 4.0kg of PTMG2000 and 1.0kg of MDI into the reactor, and react at a constant temperature of 80°C for 2.5 hours; then add 3.6kg of organic solvent dimethylacetamide to dissolve and dilute, and cool to 15°C.

[0046] 2. Mix 67.2g of ethylenediamine and 800g of dimethylacetamide evenly, and then add dropwise to the product of step 1. The time used is controlled within 30 minutes to obtain a polymer solution with a viscosity of 800 Poise;

[0047] 3. Select 616g of polyetheramine with a relative molecular weight of 400, 8.5g of ethanolamine and 2.5kg of dimethylacetamide, mix evenly, add dropwise to the product of step 2, and control the time used within 60 minutes to obtain a polymer solution with a viscosity of 5400 Poise ;

[0048] 4. Add 10g of antioxidant auxiliary agent, 15g of light stabilizer, 25g of lubricant and 15g of dyeing auxiliary agent into the product of step 3, and fully stir for 24 hours to obtain a polyurethane urea spinning solution with a viscos...

Embodiment 2

[0050] 1. Add 4.0kg of PTMG2000 and 1.8kg of MDI into the reactor, and react at a constant temperature of 60°C for 2.0 hours; then add 3.5kg of organic solvent dimethylformamide to dissolve and dilute, and cool to 15°C.

[0051] 2. Mix 60.5g of 1,2-propylenediamine and 850g of dimethylformamide evenly, and then add it dropwise to the product of step 1. The time used is controlled within 40 minutes to obtain a polymer solution with a viscosity of 720 Poise;

[0052] 3. Select 750g of polyetheramine with a relative molecular weight of 520, mix 9.8g of n-butylamine and 3.0kg of dimethylformamide evenly, and add it dropwise to the product of step 2. The time used is controlled at 75 minutes to obtain a polymer with a viscosity of 6000 Poise substance solution;

[0053] 4. Add 20g antioxidant additive, 18g light stabilizer, 30g lubricant and 10g dyeing assistant to the product of step 3, and stir thoroughly for 16 hours to obtain a polyurethane urea spinning solution with a viscosi...

Embodiment 3

[0055] 1. Add 5.0kg of PTMG2000 and 2.2kg of MDI into the reactor, and react at a constant temperature of 72°C for 1.5 hours; then add 3.2kg of organic solvent dimethylacetamide to dissolve and dilute, and cool to 15°C.

[0056] 2. Mix 72.8g of 1,5-pentanediamine and 1.00kg of dimethylacetamide evenly, and then add it dropwise to the product of step 1. The time used is controlled within 40 minutes to obtain a polymer solution with a viscosity of 900 Poise;

[0057] 3. Select 650g of polyetheramine with a relative molecular weight of 475, mix 7.6g of n-butanol and 2.0kg of dimethylacetamide evenly, add dropwise to the product of step 2, and control the time used for 60 minutes to obtain a polymer with a viscosity of 7400Poise substance solution;

[0058] 4. Add 16g antioxidant additive, 18g light stabilizer, 35g lubricant and 13g dyeing assistant to the product of step 3, and stir thoroughly for 20 hours to obtain a polyurethane urea spinning solution with a viscosity of 7700 P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com