Technological method for dyeing wool tops through plant indigo dye

A technology of indigo dye and process method, which is applied in the fields of dyeing, textiles and papermaking, and can solve problems such as yellowing of color, increase of fabric surface defects, and decline in yarn quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

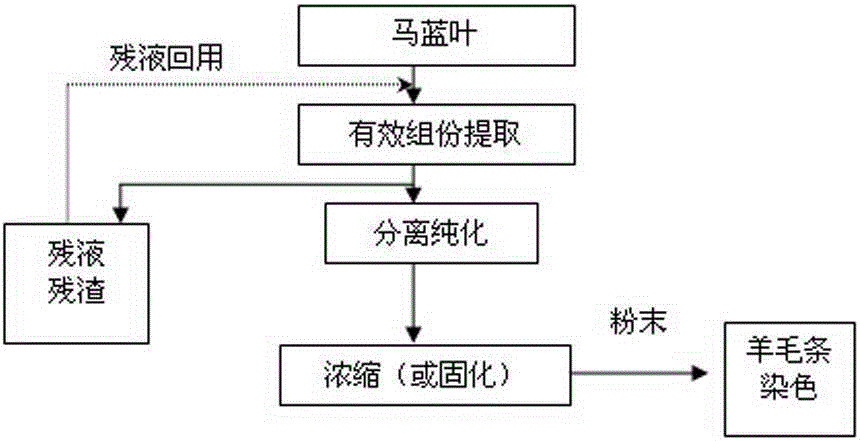

Image

Examples

Embodiment 1

[0021] Such as figure 1 As shown, the collected horse blue leaves are fully cleaned to remove impurities, dried naturally or at low temperature, and then pulverized in a pulverizer to obtain horse blue leaf plant powder residue, and the mixed solution of ethanol and water is poured into horse blue leaves In the plant powder residue, the concentration of ethanol is 60%, ultrasonic treatment is adopted, the ultrasonic power is 250W, the extraction temperature is 80°C, and the extraction time is 60min, to obtain the plant indigo extract. The extract was subjected to high-speed centrifugation at a centrifugation speed of 8500r / min and a centrifugation time of 20 minutes. After removing impurities, vacuum concentration and drying were carried out at a vacuum pressure of 0.2 MPa, a drying temperature of 60°C, and a drying time of 45 minutes to obtain plant indigo powder.

[0022] 66S Australian Merino wool (fineness 21 microns) was dyed with the plant indigo powder extracted above. ...

Embodiment 2

[0025] Fully wash the collected horse blue leaves to remove impurities, dry them naturally or at low temperature, and then pulverize them in a pulverizer to obtain the horse blue leaf plant powder residue, pour the mixed solution of ethanol and water into the horse blue leaf plant powder residue In this method, the ethanol concentration is 60%, ultrasonic treatment is adopted, the ultrasonic power is 250W, the extraction temperature is 80°C, and the extraction time is 60min, to obtain plant indigo extract. The extract was subjected to high-speed centrifugation at a centrifugation speed of 8500r / min and a centrifugation time of 20 minutes. After removing impurities, vacuum concentration and drying were carried out at a vacuum pressure of 0.2 MPa, a drying temperature of 60°C, and a drying time of 45 minutes to obtain plant indigo powder.

[0026] 70S Australian Merino mercerized wool (fineness 19.5 microns) was dyed with the plant indigo powder extracted above. Dyeing formula: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com