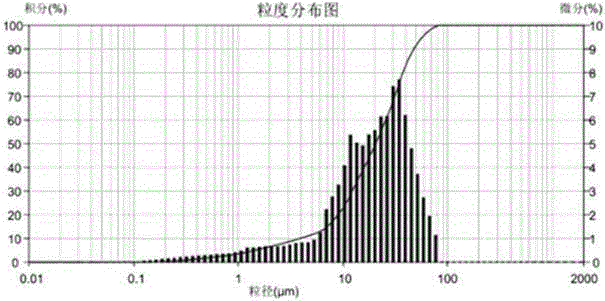

Freeze-dried oral preparation containing agomelatine and preparation method thereof

An oral preparation and freeze-drying technology, applied in the field of pharmaceutical preparations, can solve the problems of difficulty in taking ordinary tablets, long absorption process time, slow drug release speed, etc., achieve pregastric absorption and water-free delivery, and improve compliance. , the effect of accelerating the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

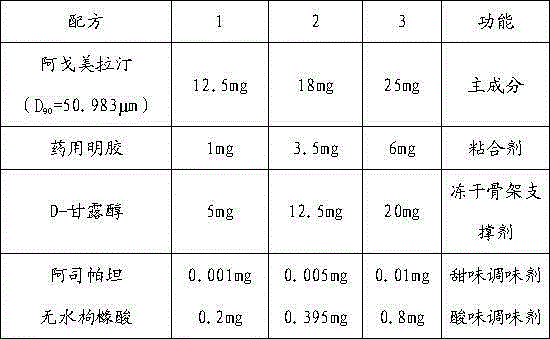

[0042] This example provides a lyophilized oral formulation containing agomelatine, the prescription of which is shown in Table 1 below.

[0043]

[0044] Table 1

[0045]The flavoring agent in the above prescription can be one of aspartame or anhydrous citric acid alone, and the dosage is 0.001mg~0.81mg. Preferably, the flavoring agent includes aspartame and anhydrous citric acid, wherein aspartame is located in the sweetness regulator, and anhydrous citric acid is used as the sourness regulator.

[0046] It is easy to understand that according to the actual use, the above-mentioned excipients of the freeze-dried preparation can also be replaced by other similar excipients, and the dosage of the above-mentioned excipients can be adjusted appropriately to meet the pharmaceutical dosage requirements of the components.

Embodiment 2

[0048] According to the prescription in Example 1, this implementation provides a preparation method of a freeze-dried oral preparation containing agomelatine, comprising the following steps:

[0049] A. Dissolve the prescribed amount of flavoring agent in 300ml of purified water, add the prescribed amount of freeze-dried skeleton proppant and binder, and stir until dissolved; then add agomelatine raw material, and continue to stir until dissolved Add purified water to make the volume to 500ml to obtain the medicinal solution;

[0050] B. The fully stirred medicinal solution in step A is left to stand, and degassed by ultrasound; the degassed medicinal solution is respectively packaged and poured into each aluminum foil blister mold, and heated at -40°C~ Quick-frozen and shaped at -120°C, then transferred to a freeze dryer for freeze-drying so that the moisture content was <2%, and a freeze-dried oral preparation was obtained.

[0051] The above-mentioned freeze-drying includ...

Embodiment 3

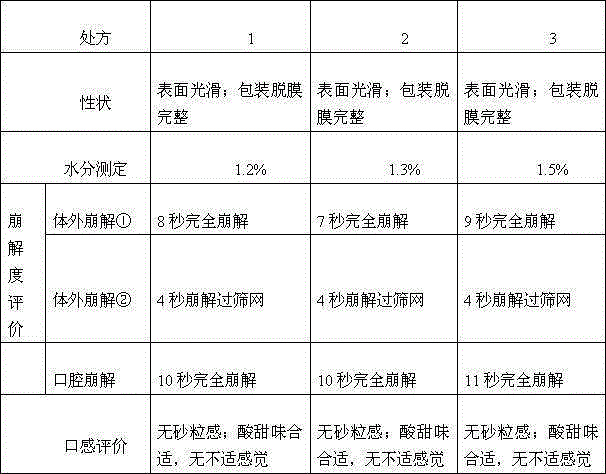

[0055] In this example, the quality evaluation of the freeze-dried oral preparation in Example 1 was carried out.

[0056] (1) Disintegration evaluation

[0057] In vitro disintegration ①: Put the product on a glass plane, add 1 drop of water (about 0.02ml) (37°C±0.5°C) at a distance of 0.5cm from the tablet surface of the product and time it accurately. The standard limit is no more than 15 seconds;

[0058] In vitro disintegration ②: Measured by (Chinese Pharmacopoeia 2015 Edition, Part IV General Rule 0921), the standard limit is no more than 10 seconds.

[0059] (2) Taste evaluation: 5 volunteers evaluated the taste, put the product on the tip of their tongues, observed the disintegration situation and recorded the oral disintegration time, whether there is a sandy feeling after complete disintegration, whether the sweet and sour taste is good, etc.

[0060] (3) Character evaluation: The surface of the product is required to be smooth; the packaging is completely stripped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com