Liquid bandage

A liquid band-aid and wound technology, applied in the medical field, can solve the problems of insufficient viscosity, permanent non-fading, and decreased effect, and achieve the effects of good biocompatibility, inhibition of abnormal proliferation, and simple and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

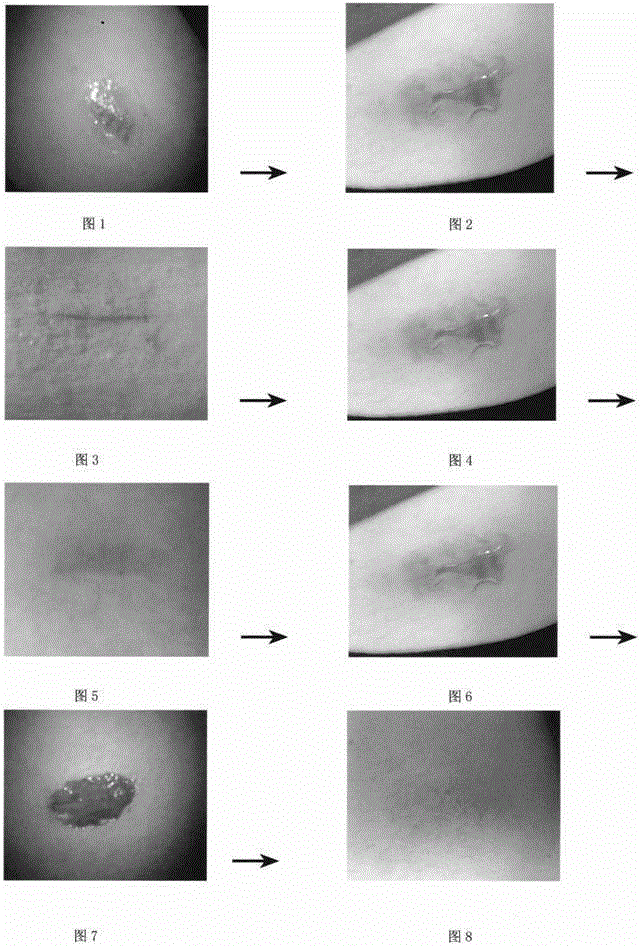

Image

Examples

Embodiment example 1

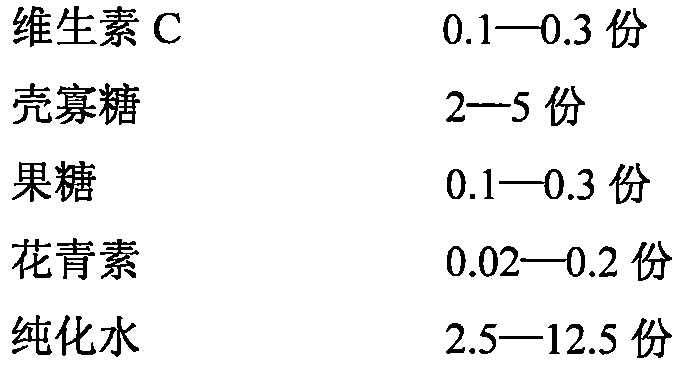

[0037]

[0038] Among them, when the raw materials such as chitosan, vitamin C, chitosan oligosaccharides, fructose, and anthocyanins are of pharmaceutical grade, and there is no pharmaceutical grade, they are required to meet the food-grade quality standards.

[0039] The preparation method is as follows:

[0040]1) At room temperature, when the humidity is below 35% or below 35%, the chitosan, vitamin C, chitooligosaccharides, fructose, and anthocyanins are passed through an 80-mesh sieve according to the components and parts by weight of Example 1 Weigh, mix, dispense into A medicine bottle, cover with medicine cap, sterilize with gamma ray for later use, and obtain A. Add purified water into medicine bottle B, cover the medicine cap, seal, sterilize and set aside.

[0041] 2) When you need to use it, pour the purified water in bottle B into bottle A, cover the medicine cap and shake it to dissolve to get a liquid bandage.

Embodiment example 2

[0043]

[0044]

[0045] Among them, when the raw materials such as chitosan, vitamin C, chitosan oligosaccharides, fructose, and anthocyanins are of pharmaceutical grade, and there is no pharmaceutical grade, they are required to meet the food-grade quality standards.

[0046] The preparation method is as follows:

[0047] 1) At room temperature, when humidity is below 35% or below 35%, chitosan, vitamin C, chitooligosaccharides, fructose, and anthocyanins are passed through an 80-mesh sieve according to the components and parts by weight ratio of Example 2 Weigh, mix, dispense into A medicine bottle, cover with medicine cap, sterilize with gamma ray for later use, and obtain A. Add purified water into medicine bottle B, cover the medicine cap, seal, sterilize and set aside.

[0048] 2) When you need to use it, pour the purified water in bottle B into bottle A, cover the medicine cap and shake it to dissolve to get a liquid bandage.

Embodiment example 3

[0050]

[0051] Among them, when the raw materials such as chitosan, vitamin C, chitosan oligosaccharides, fructose, and anthocyanins are of pharmaceutical grade, and there is no pharmaceutical grade, they are required to meet the food-grade quality standards.

[0052] The preparation method is as follows:

[0053] 1) At room temperature, when humidity is below 35% or below 35%, chitosan, vitamin C, chitooligosaccharides, fructose, and anthocyanins are passed through an 80-mesh sieve according to the components and parts by weight of Example 4 Weigh, mix, dispense into A medicine bottle, cover with medicine cap, sterilize with gamma ray for later use, and obtain A. Add purified water into medicine bottle B, cover the medicine cap, seal, sterilize and set aside.

[0054] 2) When you need to use it, pour the purified water in bottle B into bottle A, cover the medicine cap and shake it to dissolve to get a liquid bandage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com