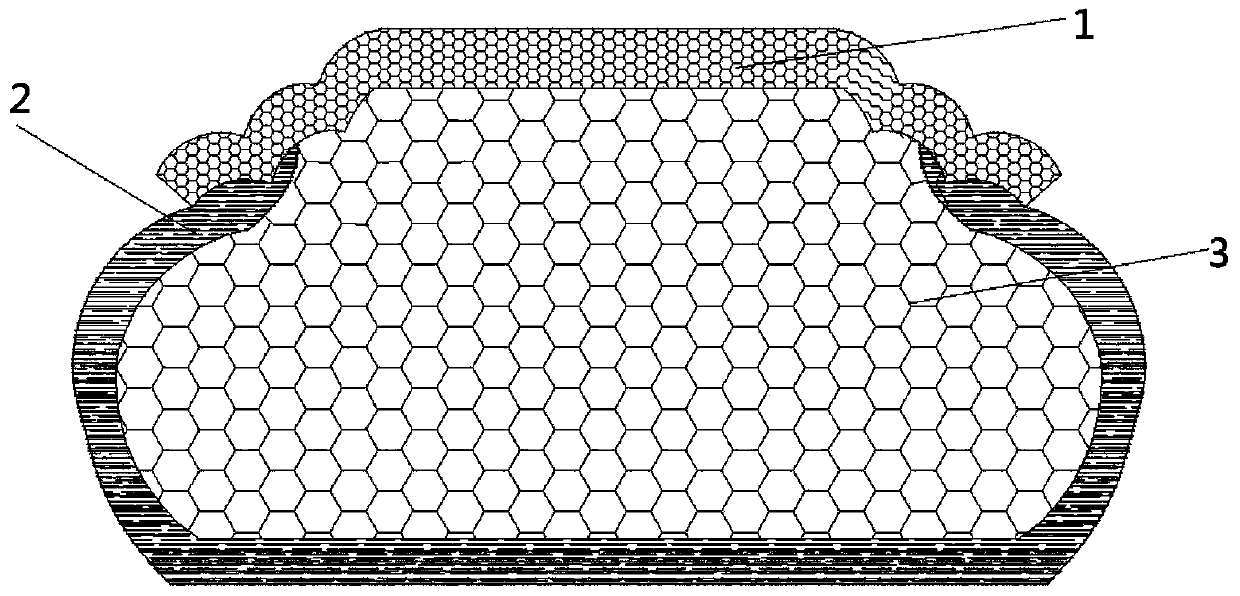

Method for making bulletproof and explosion-proof pomegranate tire

A production method and tire technology, which are applied to the reinforcement layer, tire parts, vehicle parts and other directions of pneumatic tires, can solve the problems of normal high-speed driving, etc., and achieve the effect of avoiding tire blowout and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

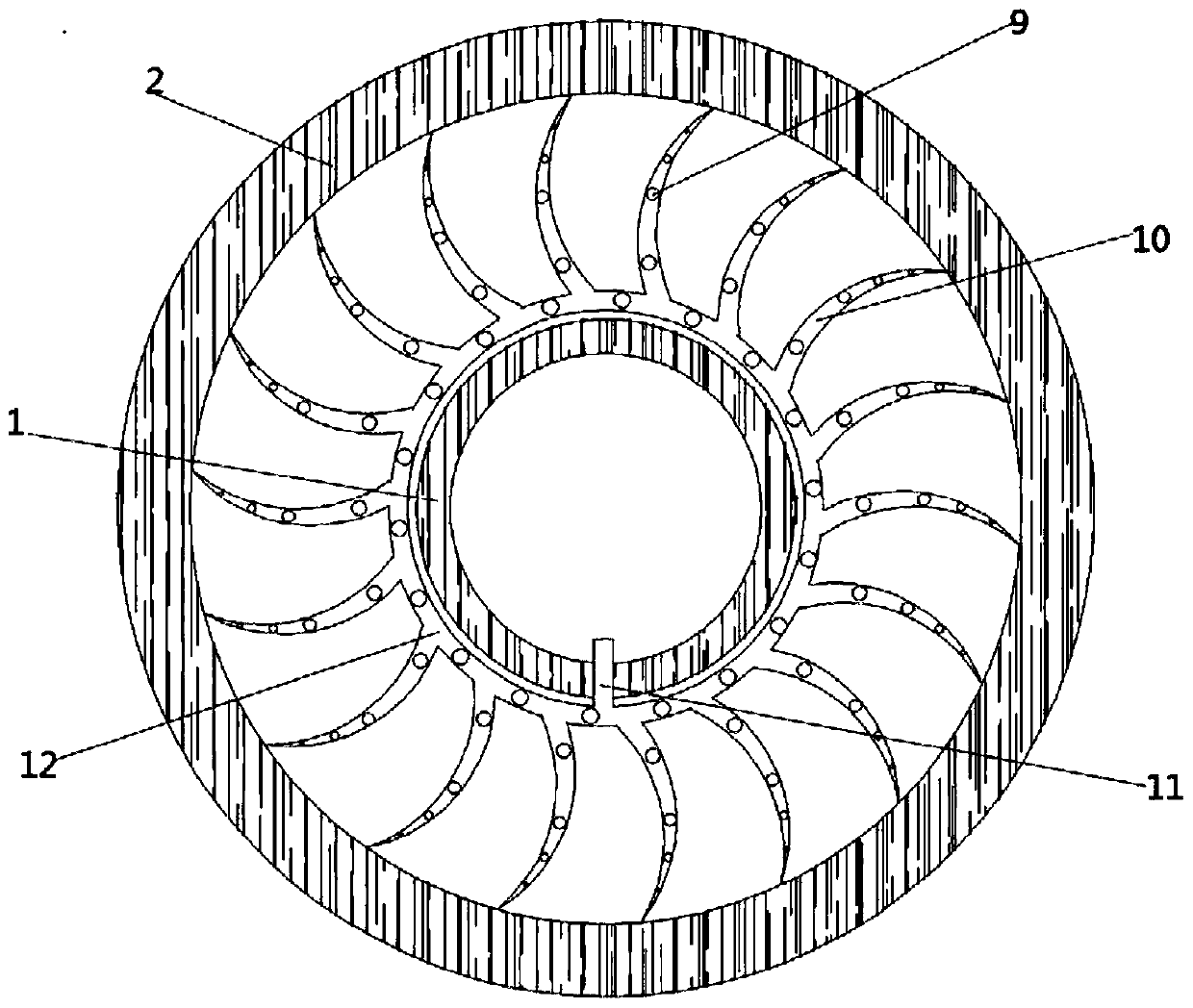

[0028] The manufacturing steps of the present invention are:

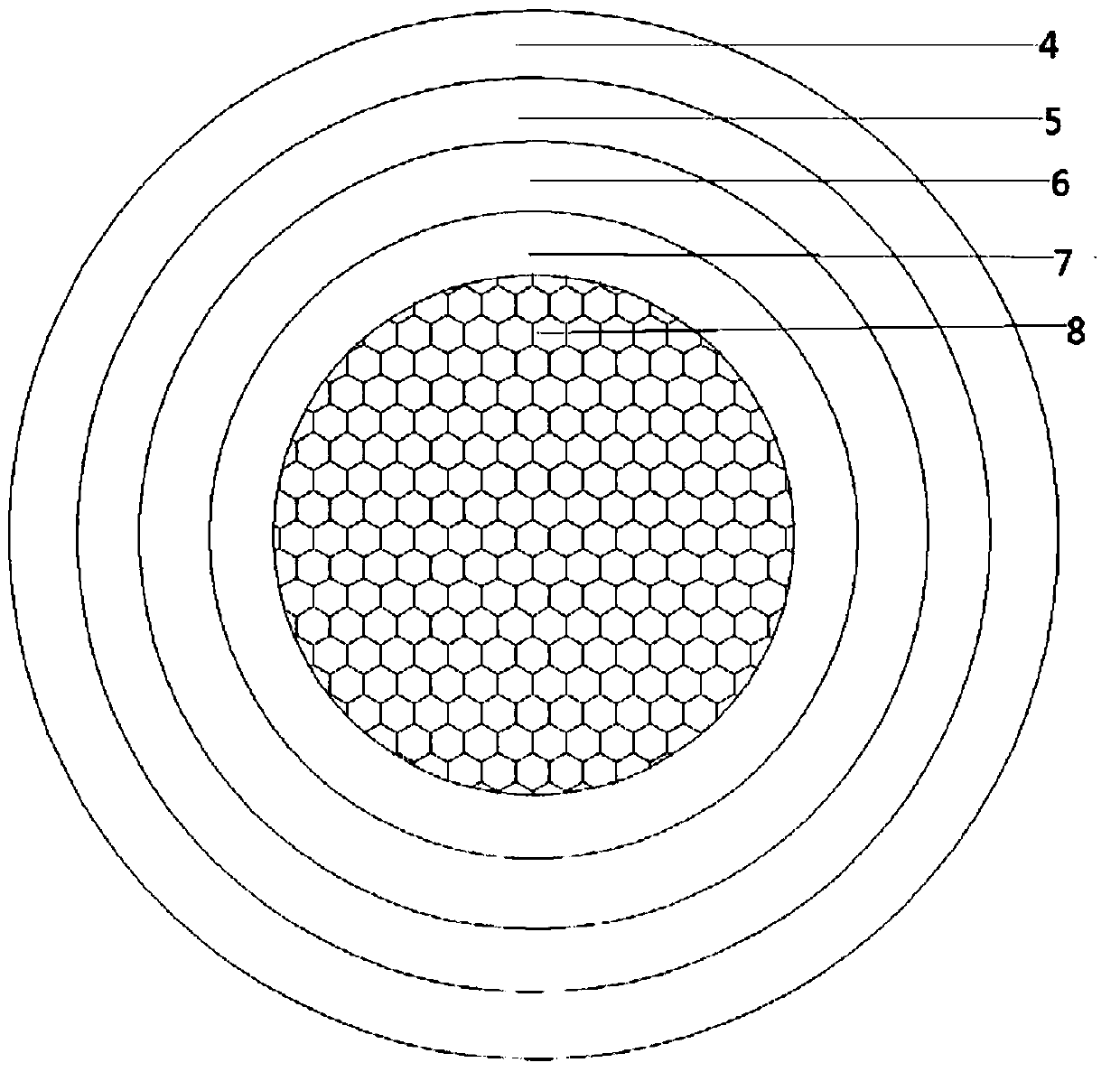

[0029] 1) Make the rubber capsule that forms the pomegranate table (see figure 2 ),

[0030] ① Prepare the gas generating agent, the mass percentage of each component of the gas generating agent: nitrocellulose 79%, combustion temperature control agent oxamide 10%, φ100um graphite grain igniter 1%, passivator camphor 2%, plasticizer benzene Dibutyl diformate 4%, combustion stabilizer titanium dioxide 2%, alcohol ether solvent 2%; The mass ratio of ethanol and ether of described alcohol ether solvent is 1:1;

[0031] The φ100um graphite grain igniter can generate a high temperature of 1000°C.

[0032] ②Make 0.5g~30g gas generating agent into a spherical shape 8,

[0033] ③ The spherical gas generating agent is dip-coated with high-molecular flame-retardant silica gel to form a high-molecular silicone rubber flame-retardant layer 7 to protect the other layers from being burned by high-temperature flames.

[0034...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com