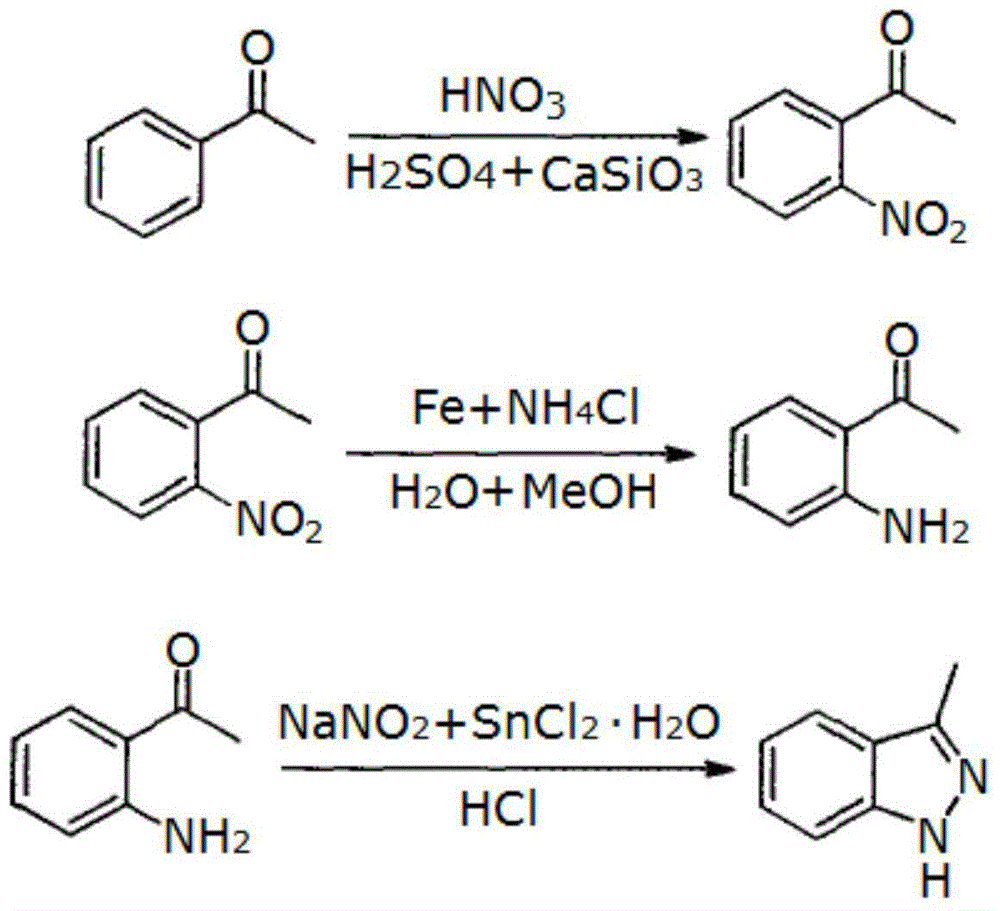

Synthesizing process of 3-methyl-1 H-indazole

A synthesis process, the technology of indazole, which is applied in the field of synthesis process of indazole derivatives, can solve the problems of low yield, unfavorable large-scale synthesis and production of 3-methyl-1H-indazole, etc., and achieve simple steps and low cost , the effect of increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] This embodiment relates to a synthesis process of 3-methyl-1H-indazole, which consists of the following steps:

[0019] Step 1: Synthesis of 2-nitroacetophenone

[0020] Slowly drop 100g of acetophenone into 500ml of sulfuric acid and nitric acid mixture (the volume ratio of concentrated sulfuric acid and concentrated nitric acid is 1:7, the temperature is -15°C), and then add 14g of 90 mesh calcium silicate powder (acetophenone and silicic acid The weight ratio of calcium powder is 1:0.14), kept stirring overnight below -15°C, then added to ice water, filtered to obtain 134g of yellow solid 2-nitroacetophenone, yield 97%, purity 99.8%, MS:m / z=165(M + ), elemental analysis: C58.1% (theoretical value 58.2%), H4.2% (theoretical value 4.2%), O29.0% (theoretical value 29.1%), N8.4% (theoretical value 8.5%), by Molecular weight and elemental analysis confirmed that it was 2-nitroacetophenone;

[0021] Step 2: Synthesis of 2-aminoacetophenone

[0022] Dissolve 110 g of t...

Embodiment 2

[0026] This embodiment relates to a synthesis process of 3-methyl-1H-indazole, which consists of the following steps:

[0027] Step 1: Synthesis of 2-nitroacetophenone

[0028] Slowly drop 100g of acetophenone into 500ml of sulfuric acid and nitric acid mixture (volume ratio of concentrated sulfuric acid and concentrated nitric acid is 1:7, temperature -15°C), and then add 23g of 80 mesh calcium silicate powder (acetophenone and silicic acid The weight ratio of calcium powder is 1:0.23), kept stirring overnight below -15°C, then added to ice water, filtered to obtain 131g of yellow solid 2-nitroacetophenone, yield 95%, purity 99.6%, MS:m / z=165(M + ), elemental analysis: C58.0% (theoretical value 58.2%), H4.2% (theoretical value 4.2%), O29.2% (theoretical value 29.1%), N8.4% (theoretical value 8.5%), by Molecular weight and elemental analysis confirmed that it was 2-nitroacetophenone;

[0029] Step 2: Synthesis of 2-aminoacetophenone

[0030] Dissolve 110 g of the above-me...

Embodiment 3

[0034] This embodiment relates to a synthesis process of 3-methyl-1H-indazole, which consists of the following steps:

[0035] Step 1: Synthesis of 2-nitroacetophenone

[0036] Slowly drop 100g of acetophenone into 500ml of sulfuric acid and nitric acid mixture (volume ratio of concentrated sulfuric acid and concentrated nitric acid is 1:7, temperature -15°C), then add 6g of 100 mesh calcium silicate powder (acetophenone and the The weight ratio of calcium silicate powder is 1:0.06), kept below -15°C and stirred overnight, then added to ice water, filtered to obtain 132g of yellow solid 2-nitroacetophenone, yield 96%, purity 99.7%, MS :m / z=165(M +), elemental analysis: C58.2% (theoretical value 58.2%), H4.1% (theoretical value 4.2%), O29.0% (theoretical value 29.1%), N8.4% (theoretical value 8.5%), by Molecular weight and elemental analysis confirmed that it was 2-nitroacetophenone;

[0037] Step 2: Synthesis of 2-aminoacetophenone

[0038] Dissolve 110 g of the above-ment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com