Water-based polyurethane dispersoid and preparation method thereof

A water-based polyurethane and prepolymer technology, applied in the field of polymer materials, can solve problems such as corneal irritation, odor, and health damage to construction workers, and achieve the effect of low VOC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

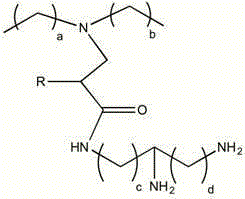

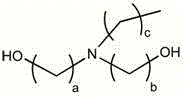

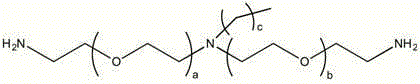

[0054] (1) Preparation of prepolymer: 100.04g of isophorone diisocyanate was added to 100g of polytetrahydrofuran ether glycol (Mn=2000) and 50.5g (Mn=232) of dihydroxy compounds containing tertiary amines (as shown in formula 17 Shown) in the mixed system, react at 80°C for 120 minutes;

[0055](2) Neutralization, chain extension and emulsification: under one atmospheric pressure, add the prepolymer and 13.04g diethanolamine to 660g saturated carbonic acid aqueous solution and emulsify and disperse at a high speed in the reaction kettle, and at the same time, pass in carbon dioxide and heat up to 80°C for reaction After 180 minutes, an aqueous polyurethane dispersion with a solid content of 30% was obtained.

[0056]

[0057] Formula 17.

Embodiment 2

[0059] (1) Preparation of prepolymer: Add 16.82g of 1,6-hexamethylene diisocyanate to 100g of polytetrahydrofuran ether diol (Mn=2000) and 50.5g (Mn=232) of dihydroxy compounds containing tertiary amines (such as In the mixed system shown in formula 17), react at 85°C for 60 minutes, then cool down to 50°C; add 68.91g of isophorone diisocyanate to the above system, and react at 80°C for 90 minutes;

[0060] (2) Neutralization, chain extension and emulsification: under one atmospheric pressure, add the prepolymer and 12.50g N-methyldiethanolamine to 660g saturated carbonic acid aqueous solution and emulsify and disperse at a high speed in the reactor, and at the same time pass in carbon dioxide, and raise the temperature to After reacting at 80°C for 180 minutes, an aqueous polyurethane dispersion with a solid content of 30% was obtained.

Embodiment 3

[0062] (1) Preparation of prepolymer: Add 100.04g of isophorone diisocyanate to 100g of polytetrahydrofuran ether glycol (Mn=2000), 25g of methyl methacrylate, 10g of butyl methacrylate and 50.5g of (Mn= 232) In the mixed system of dihydroxy compounds containing tertiary amines (as shown in formula 17), react at 80°C for 120 minutes;

[0063] (2) Neutralization, chain extension and emulsification: under one atmospheric pressure, add the prepolymer and 13.04g diethanolamine to 660g saturated carbonic acid aqueous solution and emulsify and disperse at a high speed in the reactor, and at the same time introduce carbon dioxide, heat up to 80°C for reaction After 180 minutes, a waterborne polyurethane and acrylate mixed dispersion with a solid content of 37% was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com