Preparation method of cellulose nanocrystal cholesteric liquid crystal texture anti-counterfeiting mark

A cholesteric liquid crystal and nano-crystal technology, applied in stamps, instruments, identification devices, etc., can solve the problems of no packaging texture research, etc., and achieve the effect of size balance, good stability, and clear lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A preparation method of a cellulose nanocrystal cholesteric liquid crystal texture anti-counterfeiting mark, comprising the following process steps:

[0022] The microcrystalline cellulose described in step a) prepares the nanocrystal suspension, and its specific method steps include:

[0023] (1) Weigh 1-10g of microcrystalline cellulose and add it to 50-100ml of 50-65wt% sulfuric acid, and carry out acidic hydrolysis for 30-120min under magnetic stirring at 40-55°C;

[0024] (2) Add deionized water to terminate the above reaction, and the obtained solution is centrifuged several times and then transferred to a dialysis bag for dialysis for 1 to 2 days to obtain a nanocrystal suspension, which is filtered and stored for later use;

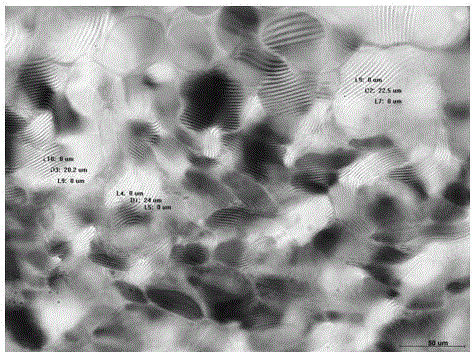

[0025] Step b) Observing the cholesteric liquid crystal texture pattern with a polarizing microscope, the specific method steps include:

[0026] (1) Take 10-25ml of the above-mentioned nanocrystal suspension, conduct ultrasonic treatment ...

Embodiment 1

[0036] Microcrystalline cellulose to prepare nanocrystalline suspension: (1) Weigh 5g of microcrystalline cellulose and add it to 80ml of 64wt% sulfuric acid, and carry out acidic hydrolysis for 80min under constant temperature water bath at 45°C. (2) Add deionized water to terminate the above reaction, After the obtained solution was left to stand, centrifuge at a speed of 5000rpm / m for 10min with a centrifuge, then wash the precipitate, centrifuge again, and repeat several times until no obvious precipitate appears, then transfer the solution to a dialysis bag for dialysis for 2 days, after filtration Save for future use, the pH value of the nanocrystal suspension thus obtained is 5.5, and the concentration is 0.8wt%.

[0037] Observing the texture pattern of cholesteric liquid crystal with a polarizing microscope: (1) Measure 20ml of the above-mentioned nanocrystal suspension with a graduated cylinder, and ultrasonically treat it in an ice-water bath for 5 minutes (ultrasoni...

Embodiment 2

[0039] Microcrystalline cellulose to prepare nanocrystalline suspension: (1) Weigh 5g of microcrystalline cellulose and add it to 80ml of 64wt% sulfuric acid, and carry out acidic hydrolysis for 80min under constant temperature water bath at 45°C. (2) Add deionized water to terminate the above reaction, After the obtained solution was left to stand, centrifuge at a speed of 5000rpm / m for 10min with a centrifuge, then wash the precipitate, centrifuge again, and repeat several times until no obvious precipitate appears, then transfer the solution to a dialysis bag for dialysis for 2 days, after filtration Save for future use, the pH value of the nanocrystal suspension thus obtained is 5.5, and the concentration is 0.8wt%.

[0040] Observing the texture pattern of cholesteric liquid crystal with a polarizing microscope: (1) Take 0.2 ml of the above-mentioned nanocrystal suspension and drop it on a glass slide with a plastic dropper. (2) After the suspension is dried, observe it u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com