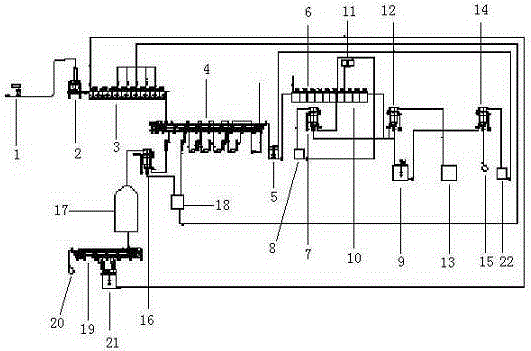

Production method and device for extracting rare earth from monazite ores

A technology for monazite ore and rare earth, which is applied in the field of rare earth extraction, can solve the problems of physical injury of operators, high labor intensity of workers, and high production cost, and achieve the effects of reducing energy consumption, reducing impurity removal procedures, and reducing production and operation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Take 320 mesh, 53% rare earth content of monazite ore powder 300g, temperature 155℃ as an example

[0051] Process steps:

[0052] 1. Weigh 300g of monazite ore powder into the reactor;

[0053] 2. Prepare NaOH solution with 288g of solid alkali with a content of 96% and 1006ml of water and add it to the reactor;

[0054] 3. Start the reactor mixer and heater, adjust the stirring speed to 180 rpm, and start timing after boiling;

[0055] 4. When the temperature rises to 155°C, the temperature is kept constant, controlled at 155±5°C, and the reaction time is controlled at 240±10 minutes;

[0056] 5. Decomposition products were diluted, filtered, washed, and dried. The total volume after dilution was 3568ml, and the washing water was 1200ml; the output of phosphorus lye was 3425ml, and the output of alkali cake was 325.2g;

[0057] 6. Cool and crystallize the phosphorus lye, and start to filter when the temperature is lowered to 40 degrees, and produce 400g of trisodiu...

Embodiment 2

[0063] Take 320 mesh, 53% rare earth content of monazite ore powder 300g, temperature 130℃ as an example

[0064] Process steps:

[0065] 1. Weigh 300g of monazite ore powder into the reactor;

[0066] 2. Prepare NaOH solution with 288g of solid alkali with a content of 96% and 1006ml of water and add it to the reactor;

[0067] 3. Start the reactor mixer and heater, adjust the stirring speed to 180 rpm, and start timing after boiling;

[0068] 4. When the temperature rises to 130°C, the temperature is kept constant, controlled at 130±5°C, and the reaction time is controlled at 380±10 minutes;

[0069] 5. Decomposition products were diluted, filtered, washed, and dried. The total volume after dilution was 3592ml, and the washing water was 1200ml; the output of phosphorus lye was 3425ml, and the output of alkali cake was 325.2g;

[0070] 6. Cool and crystallize the phosphorus lye, and start to filter when the temperature is lowered to 40 degrees, and produce 398g of trisodiu...

Embodiment 3

[0076] Take 320 mesh, 53% rare earth content of monazite ore powder 300g, temperature 170℃ as an example

[0077] Process steps:

[0078] 1. Weigh 300g of monazite ore powder into the reactor;

[0079] 2. Prepare NaOH solution with 288g of solid alkali with a content of 96% and 1006ml of water and add it to the reactor;

[0080] 3. Start the reactor mixer and heater, adjust the stirring speed to 180 rpm, and start timing after boiling;

[0081] 4. When the temperature rises to 170°C, the temperature is kept constant, controlled at 170±5°C, and the reaction time is controlled at 240±10 minutes;

[0082] 5. Decomposition products were diluted, filtered, washed, and dried. The total volume after dilution was 3521ml, and the washing water was 1200ml; the output of phosphorus lye was 3420ml, and the output of alkali cake was 325g;

[0083] 6. Cool and crystallize the phosphorus lye, and start to filter when the temperature is lowered to 40 degrees, and produce 399g of trisodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com