Electrostatic spinning device for preparing axial orderly arranged tubes by means of magnetic field inducement

An electrospinning, ordered arrangement technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problem of less research on three-dimensional ordered tubular stents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

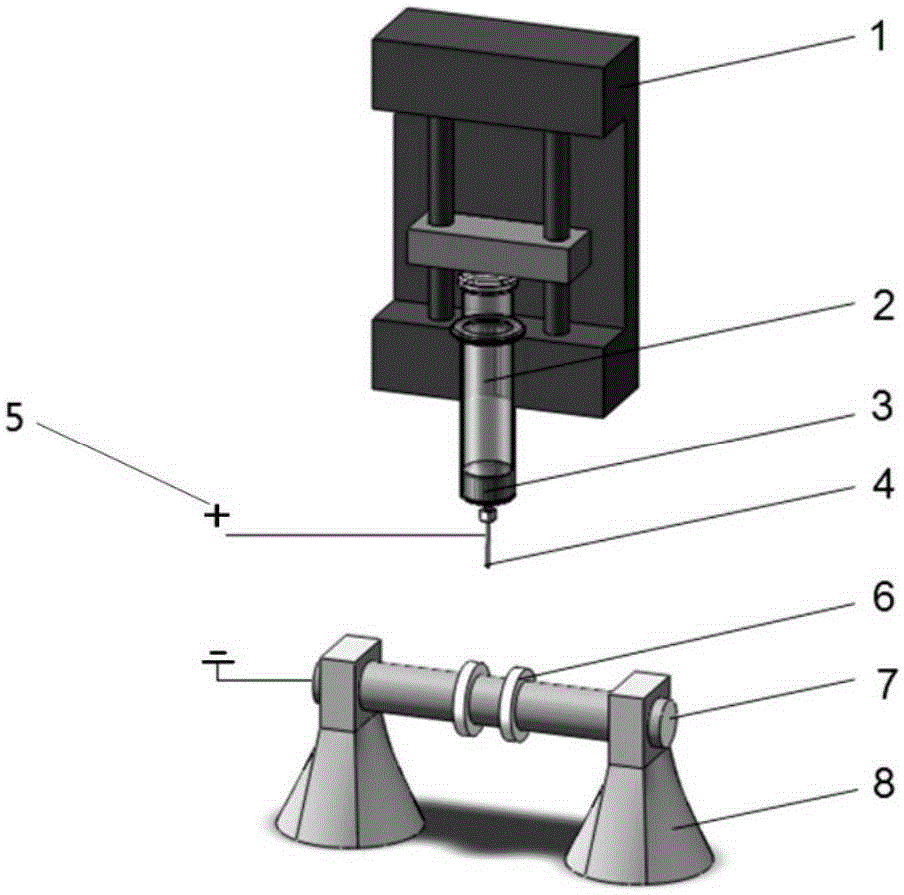

[0020] Embodiment 1, adopt as figure 1 The device shown performs electrospinning. Poly(lactic-co-glycolic acid) (PLGA) (Mv=5×10 4 KDa) was dissolved in N,N-dimethylformamide (DMF) / dichloromethane, the volume ratio of DMF and dichloromethane was 1:1, and the mass volume ratio of PLGA was 36wt.%. in the reservoir. The high-voltage DC power supply voltage is 12kV, the positive pole is connected to the needle of the stainless steel syringe, and the rotation speed of the roller is controlled by the motor and grounded through the wire. The micro-injection pump fixed with the liquid reservoir is placed vertically, and the distance from the stainless steel injection needle tip to the drum is 15 cm. The outer diameter of the ring magnet is 7cm, the inner diameter is 3cm (consistent with the outer diameter of the drum), and the distance between the two magnets is 5cm. In this example, the diameter of the drum is 3cm, and the rotating speed is 2000r / min. The inner diameter of the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com