Graphene transparent conductive film and preparation method thereof

A technology of transparent conductive film and graphene, which is applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of inapplicability to large-scale production, high temperature in the growth process, and high production cost, so as to promote wide application and low cost , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of the graphene transparent conductive film described in the present embodiment comprises the following steps:

[0026] 1. Prepare graphene oxide by the Hummers method, take 0.5 g of the graphene oxide, disperse it in 100 g of ethanol to obtain mixture A, and raise the temperature to 60 ° C;

[0027] Dissolve 1g of vinyltrimethoxysilane in 10g of ethanol to obtain a mixed solution with a concentration of 10%, that is, mixture B; then slowly add mixture B to mixture A, stir and react at 60°C for 3h to obtain mixture C;

[0028] Add 5ml of hydrazine hydrate to the mixture C, stir and react at 75°C for 10h; finally, filter and wash with ethanol and deionized water respectively, and freeze-dry to obtain modified reduced graphene powder;

[0029] 2. Disperse 0.1 g of the modified reduced graphene powder in 20 g of ethyl acetate solvent by ultrasonic dispersion to obtain a graphene solution;

[0030] 3. Mix the graphene solution and polyurethane in a m...

Embodiment 2

[0032] The preparation method of the graphene transparent conductive film described in the present embodiment comprises the following steps:

[0033] 1. Prepare graphene oxide by the Hummers method, take 0.5 g of the graphene oxide, disperse it in 100 g of ethanol to obtain mixture A, and raise the temperature to 60 ° C;

[0034] Dissolve 1g of vinyltrimethoxysilane in 10g of ethanol to obtain a mixed solution with a concentration of 10%, that is, mixture B, then slowly add mixture B to mixture A, stir and react at 60°C for 3h to obtain mixture C;

[0035] Add 5ml of hydrazine hydrate to the mixture C, stir and react at 75°C for 10h; finally, filter and wash with ethanol and deionized water respectively, and freeze-dry to obtain modified reduced graphene powder;

[0036] 2. Disperse 0.1 g of the modified reduced graphene powder in 20 g of ethyl acetate solvent by ultrasonic dispersion to obtain a graphene solution;

[0037] 3. Mix the graphene solution and polyurethane in a m...

Embodiment 3

[0040] The preparation method of the graphene transparent conductive film described in the present embodiment comprises the following steps:

[0041] 1. Prepare graphene oxide by the Hummers method, take 0.5 g of the graphene oxide, disperse it in 100 g of ethanol to obtain mixture A, and raise the temperature to 60 ° C;

[0042] Dissolve 1g of vinyltrimethoxysilane in 10g of ethanol to obtain a mixed solution with a concentration of 10%, that is, mixture B, then slowly add mixture B to mixture A, stir and react at 60°C for 3h to obtain mixture C;

[0043] Add 5ml of hydrazine hydrate to the mixture C, stir and react at 75°C for 10h; finally, filter and wash with ethanol and deionized water respectively, and freeze-dry to obtain modified reduced graphene powder;

[0044] 2. Disperse 0.1 g of the modified reduced graphene powder in 20 g of ethyl acetate solvent by ultrasonic dispersion to obtain a graphene solution;

[0045] 3. Mix the graphene solution and polyurethane in a m...

PUM

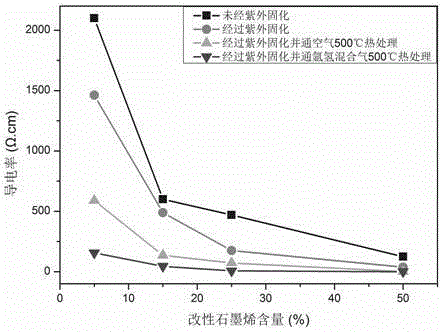

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com