Method for synthesizing an S and N synergistic mesoporous carbon material with excellent ORR and lithium-ion electric performance through one-step method

A synergistic, mesoporous carbon technology, applied in nanotechnology, circuits, electrical components, etc. for materials and surface science, can solve problems such as high cost, low yield, and difficulty in industrialization, and achieve high lithium battery performance, The effect of high yield, huge economic benefit and social benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

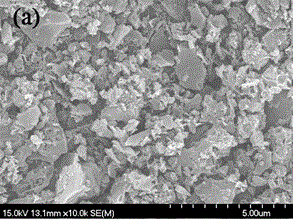

[0068] The preparation of embodiment 1 mesoporous carbon material SNPC-800

[0069] Weigh ZnCl 2 (0.8815g), 2-aminothiazole (0.1282g), ZnCl 2 (0.8815g), ZnCl 2 2-aminothiazole placed on two layers of ZnCl 2 In the middle of the material, in a sandwich shape, placed in a quartz boat, placed in a tube furnace, N 2 (The speed is 30ml / min) under the atmosphere, the temperature is raised to 800°C at 5°C / min, and kept for 8h, a black powder is obtained, and the residual ZnCl is washed with 35% hydrochloric acid 2 , washed three times with deionized water and ethanol, dried in a vacuum oven at 80°C for 3 h, and finally in a tube furnace for N 2 (speed 30ml / min) atmosphere, 200 ° C for 2 hours, to obtain the final product S, N co-doped mesoporous carbon material SNPC-800.

[0070] Mix the prepared S, N co-doped mesoporous carbon material SNPC-800, ethanol and nafion at a ratio of 2mg: 1.8mL: 200μL, ultrasonically disperse evenly, drop it on the electrode, and then Dry and make a...

Embodiment 2

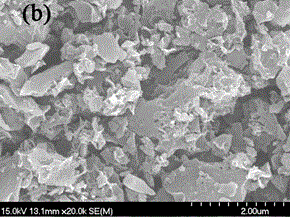

[0072] Preparation of Example 2 mesoporous carbon material SNPC-700

[0073] Weigh ZnCl 2 (0.8815g), 2-aminothiazole (0.1282g), ZnCl 2 (0.8815g), ZnCl 2 2-aminothiazole placed on two layers of ZnCl 2 In the middle of the material, in a sandwich shape, placed in a quartz boat and placed in a tube furnaceN 2 (30ml / min) under the atmosphere, the temperature was raised to 700°C at 5°C / min, and kept for 8h to obtain a black powder, which was washed with 35% hydrochloric acid to remove residual ZnCl 2 , washed five times with deionized water and ethanol, dried in a vacuum oven at 80°C for 3 h, and finally in a tube furnace with N 2 (30ml / min) atmosphere, 200°C for 2h, the final product S, N co-doped mesoporous carbon material SNPC-700 was obtained.

[0074] The test conditions for catalytic oxygen reduction reaction performance are the same as those in Example 1.

Embodiment 3

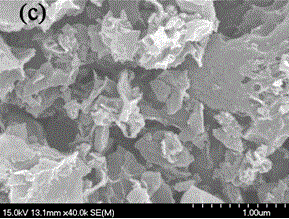

[0075] Example 3 Preparation of Mesoporous Carbon Material SNPC-600

[0076] Weigh ZnCl 2 (0.8815g), 2-aminothiazole (0.1282g), ZnCl 2 (0.8815g), ZnCl 2 2-aminothiazole placed on two layers of ZnCl 2 In the middle of the material, in a sandwich shape, placed in a quartz boat and placed in a tube furnaceN 2 (30ml / min) under the atmosphere, the temperature was raised to 600°C at 5°C / min, and kept for 8h to obtain a black powder, which was washed with 35% hydrochloric acid to remove residual ZnCl 2 , washed several times with deionized water and ethanol, dried in a vacuum oven at 80 °C for 3 h, and finally in a tube furnace for N 2 (30ml / min) atmosphere, 200°C for 2h, the final product S, N co-doped mesoporous carbon material SNPC-600 was obtained.

[0077] The test conditions for catalytic oxygen reduction reaction performance are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com