Tin-titanium-silicon molecular sieve and preparation method and application thereof, and method for hydroxylation of phenol

A technology of tin-titanium-silicon molecular sieve and silicon molecular sieve, which is applied in molecular sieve catalysts, chemical instruments and methods, and the preparation of organic compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

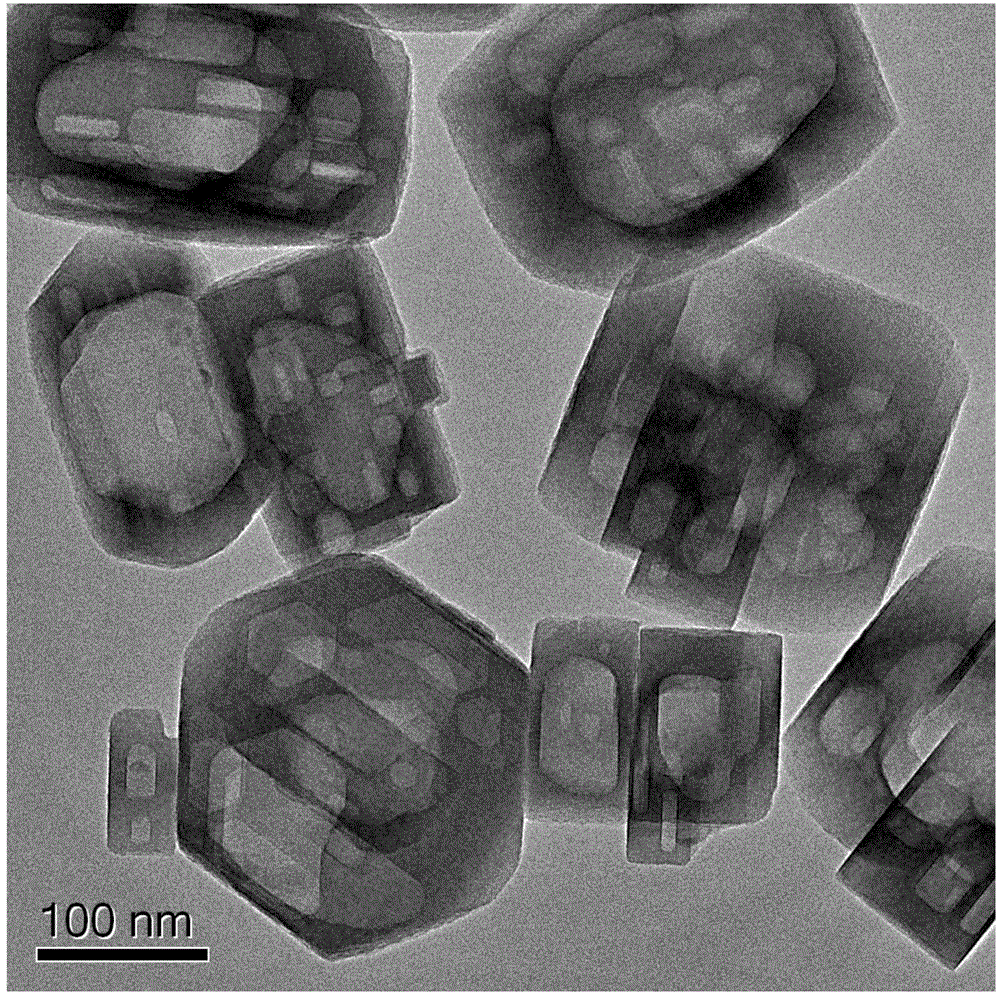

Image

Examples

preparation example Construction

[0038] The aforementioned tin-titanium-silicon molecular sieve of the present invention has the advantages of high catalytic activity, good selectivity, and is conducive to the diffusion of reactants and products. Tin-titanium-silicon molecular sieves are sufficient. According to a preferred embodiment of the present invention, the present invention provides a method for preparing tin-titanium-silicon molecular sieves, wherein the method includes:

[0039] (1) contacting the tin source, the titanium source and the templating agent in the presence of an aqueous solvent to obtain the first mixture;

[0040] (2) mixing the first mixture with silicon molecular sieves to obtain a second mixture;

[0041] (3) Under hydrothermal crystallization conditions, the second mixture is crystallized.

[0042] According to the present invention, the temperature of the contact can be selected in a wide range. For the preferred step (1) of the present invention, the conditions of the contact in...

Embodiment 1

[0086] (1) At 25°C, stirring and contacting tetrapropylammonium hydroxide aqueous solution (concentration: 15% by weight) with tetrabutyl titanate and tin tetrachloride pentahydrate for 30 minutes to obtain a mixture;

[0087] (2) At 60°C, add silicon molecular sieve S-1 to the above mixture and stir for 0.5h to obtain the mixture (during this contact process, add water or not add water as required, if the feeding in step (1) can meet the requirement of water Feeding requirements, there is no need to add water, if it is not met, you can add water when the mixture containing tetrapropylammonium hydroxide, tetrabutyl titanate and tin chloride is stirred and contacted with silicon molecular sieve, or distill off water, and the rest Embodiment is similar, no longer repeat description); Wherein, the molar ratio that guarantees each material is: silicon source (silicon molecular sieve): alkali source templating agent (tetrapropyl ammonium hydroxide): titanium source (tetrabutyl titan...

Embodiment 2

[0099] (1) At 25°C, stirring and contacting tetrapropylammonium hydroxide aqueous solution (concentration: 20% by weight) with tetrabutyl titanate and tin tetrachloride pentahydrate for 30 minutes to obtain a mixture;

[0100] (2) At 25°C, add silicon molecular sieve S-1 to the above mixture and stir for 0.5h to obtain the mixture; wherein, ensure that the molar ratio of each substance is: silicon source (silicon molecular sieve): alkali source template (four Propyl ammonium hydroxide): titanium source (tetrabutyl titanate): tin source (tin tetrachloride): water=100:15:2:0.1:200, wherein the silicon source is SiO 2 In terms of titanium source as TiO 2 Tin source is calculated as tin element;

[0101] (3) Transfer the above mixture into a sealed stainless steel reaction kettle, crystallize at 160°C for 120 hours under autogenous pressure, filter the resulting crystallized product, wash with water, and dry at 110°C for 120 minutes, then heat at 550°C Roasting at high temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| External specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com