A kind of concrete synergist and preparation method thereof

A concrete synergist and material technology, applied in the field of building materials, can solve the problems of insignificant reduction in the amount of cementitious materials, poor workability of concrete, and poor fluidity, so as to facilitate industrial production, increase concrete strength, improve and efficiencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

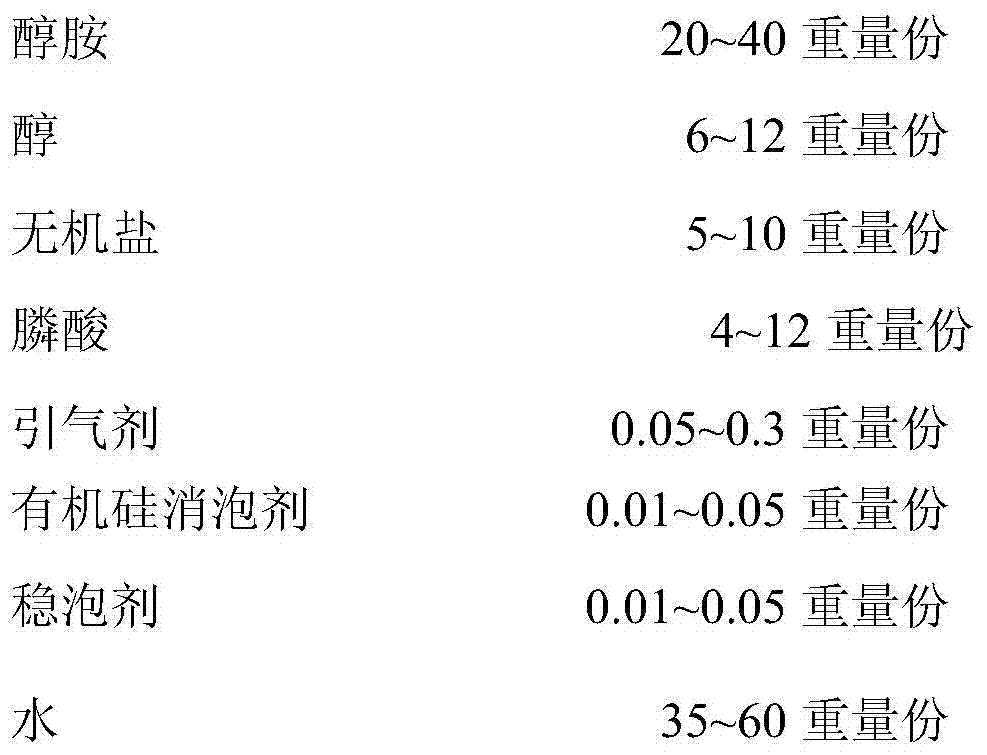

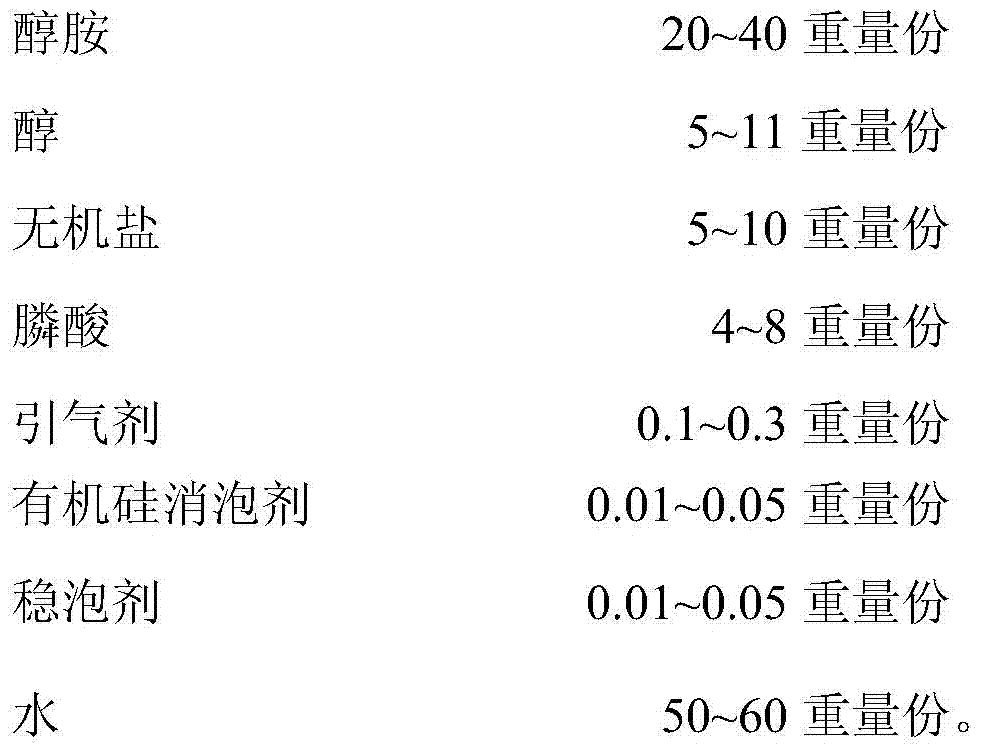

Method used

Image

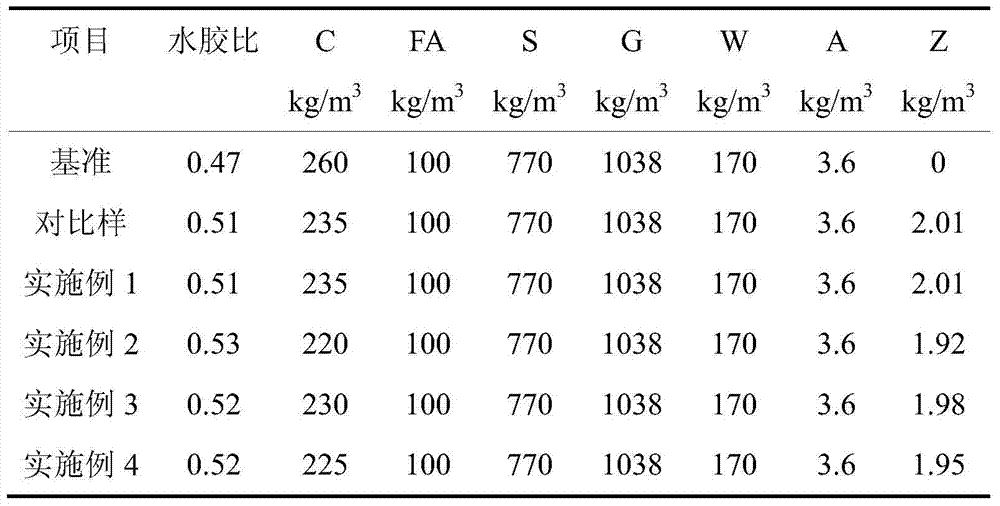

Examples

Embodiment 1

[0032] In parts by weight, take 5 parts of sodium pyrophosphate, 4 parts of hydroxyethylidene diphosphonic acid and 55 parts of water, add them into the reactor, and stir for 10 minutes; then add 20 parts of monoethanol diisopropanolamine, diethylene glycol 5 parts and 6 parts of 1,5-pentanediol, stirred for 25 minutes; then added 0.3 parts of sodium dodecylbenzenesulfonate, stirred evenly for 15 minutes; then slowly added 0.01 parts of Dow Corning DC544, and stirred slowly for 20 minutes; finally added two (Hydrogenated tallow-based) phthalic acid amide 0.01 part, uniformly stirred for 10 minutes to obtain the concrete synergist.

Embodiment 2

[0034] In parts by weight, take 8 parts of sodium pyrophosphate, 5 parts of 2-phosphonic acid butane-1,2,4-tricarboxylic acid and 60 parts of water, add them into the reactor, stir for 10 minutes; 40 parts of ethyl ethanolamine and 10 parts of 1,5-pentanediol, stirred for 35 minutes; then added 0.06 parts of sodium cetyl benzene sulfonate and 0.09 parts of sodium lauryl sulfate, stirred evenly for 20 minutes; then slowly added Figure 0.04 part of SAG 470, stirred slowly for 25 minutes; finally added 0.03 part of di(hydrogenated tallow) phthalic acid amide, and stirred evenly for 20 minutes to obtain the concrete synergist.

Embodiment 3

[0036] In parts by weight, 5 parts of potassium pyrophosphate, 4 parts of aminotrimethylene phosphonic acid, 8 parts of ethylenediamine tetramethylene phosphonic acid and 60 parts of water are added to the reactor and stirred for 10 minutes; , 25 parts of N-diethylpropanolamine, 3 parts of diethylene glycol and 3 parts of 1,5-pentanediol, stirred slowly for 25 minutes; then added 0.3 parts of sodium cetyl alcohol ether sulfate, and stirred evenly for 10 minutes; Slowly add 0.05 parts of South Korea's Sano Puke HS-DEFOAMER567, and stir for 15 minutes; finally add 0.05 parts of di(hydrogenated tallow) phthalic acid amide, and stir for 15 minutes to obtain the concrete synergist.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com