Method for preparing cyclohexanone-oxime from cyclohexanone through liquid-phase ammoximation

A technology of cyclohexanone liquid-phase ammonia oxime and cyclohexanone oxime, which is applied in the field of green chemistry, can solve problems such as weak alkali resistance, easy inactivation, and difficult separation and recovery, and achieve the effect of reducing separation costs and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Stir and mix butyl titanate and phosphoric acid according to different molar ratios, transfer the mixture into a polytetrafluoroethylene-lined stainless steel reaction kettle, put it in a constant temperature drying oven at 180°C for 6 hours, cool to room temperature, and centrifuge. Fully washed to neutral, vacuum dried overnight at 80°C. The titanium hydrogen phosphate catalysts synthesized with Ti / P molar ratios of 1:28.4, 1:38, 1:50, and 1:65.4 were designated as TP-1, TP-2, TP-3, and TP-4, respectively.

Embodiment 2

[0018] In the phosphoric acid solution, add ethyl orthosilicate (containing an equal volume of absolute ethanol), CTAB and butyl titanate, stir vigorously at different temperatures for 8 hours, cool to room temperature, centrifuge, and fully wash until neutral. Dry overnight at 80°C under vacuum. Among them, the molar ratio of butyl titanate, phosphoric acid, ethyl orthosilicate and CTAB is 1:4:3.93:0.018. The titanium hydrogen phosphate catalysts synthesized at 110°C, 140°C, and 180°C are designated as TP-5, TP-6, and TP-7, respectively.

Embodiment 3

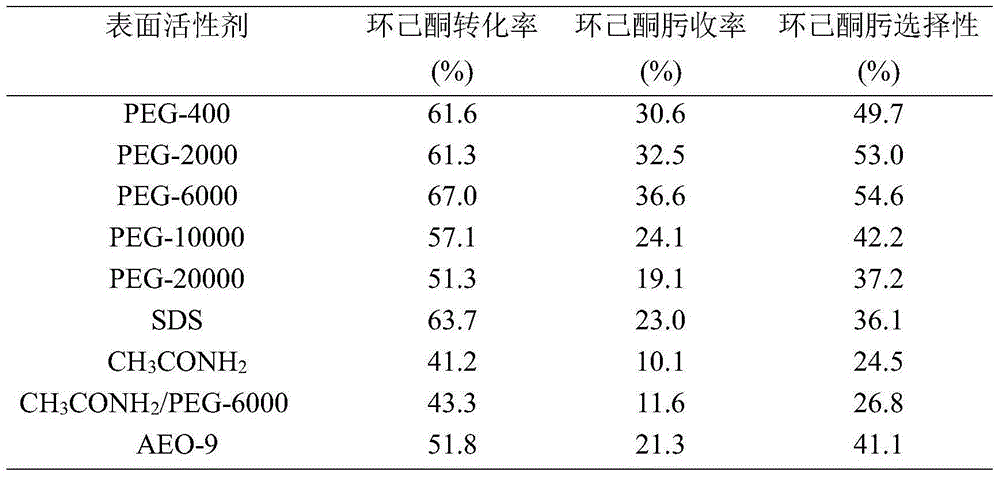

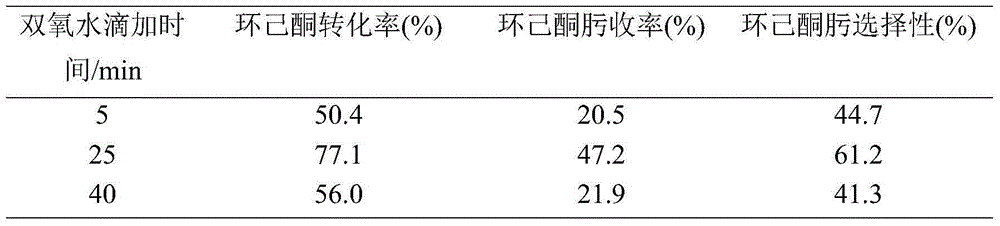

[0020] In a 100ml round-bottomed three-neck flask equipped with a condenser tube and a thermometer, add 0.5g of zirconium hydrogen phosphate (the catalyst for zirconium hydrogen phosphate is commercially available, and dry it overnight before use), 1ml of surfactant AEO-9, co-surfactant 2ml of tert-butanol, 4ml of water, 0.01mol of cyclohexanone (0.9814g, the molar mass of cyclohexanone is 98.14g / mol), put it in a constant temperature water bath at 70°C, stir at a speed of 495r / min, and make a disposable Add 0.05molNH 3 (mass fraction is 25% ammonia solution), then dropwise add 0.02mol of H 2 o 2 (Hydrogen peroxide solution with a mass fraction of 30%), the dropwise addition time is 25 minutes, and after the dropwise addition is completed, the reaction is carried out at a constant temperature of 70° C. for 4 hours. After the reaction, the temperature of the reaction solution was down to room temperature, the reaction solution was extracted several times with toluene, the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com