Method for preparing epoxy novolac nanometer anticorrosive paint

An anti-corrosion coating, epoxy phenolic technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of low curing shrinkage, slow curing reaction, low construction efficiency, etc. The effect of penetration and quick construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in combination with specific embodiments.

[0030] The preparation method of a kind of epoxy phenolic nano anticorrosion coating of the present embodiment, comprises the steps:

[0031] Step 1: Prepare Component A:

[0032] ① Weigh the raw materials of component A according to the formula: 8% epoxy resin, 16% phenolic resin, 18% mixed solvent, 1.2% nano particles, 0.3% coupling agent KH-5500.3%, 6% zinc phosphate, 18% talcum powder, Organic bentonite 9%, precipitated barium sulfate 18%, defoamer 2.3%, leveling agent 1.6% and surfactant Triton X-100 1.6%;

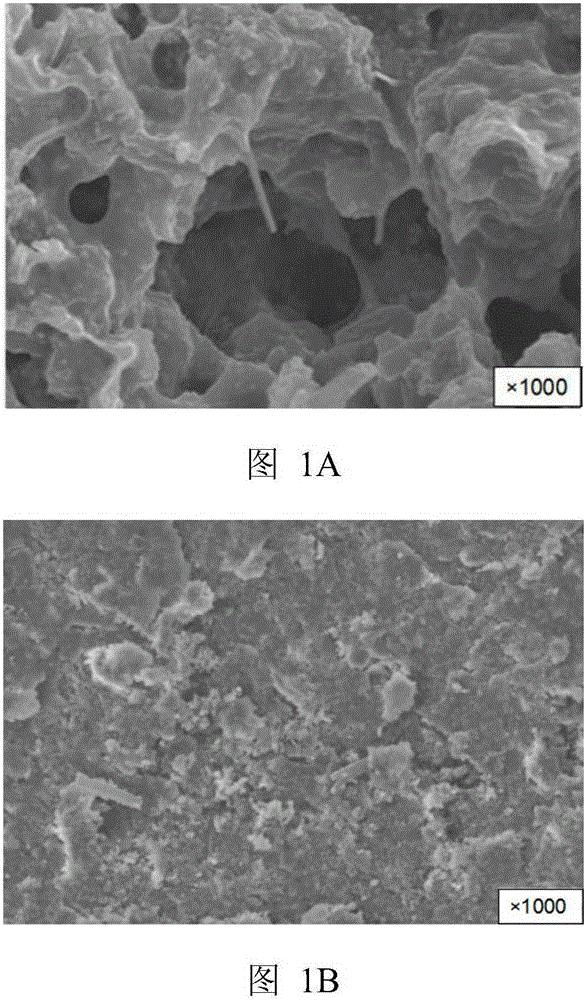

[0033] ②Use a muffle furnace to calcinate nanoparticles at 600°C for 3 hours, add them to a three-necked flask after cooling, and disperse them with absolute ethanol to form a nanoparticle suspension with a mass fraction of 4.8%; stir for 10 minutes, and then add the modified coupling agent dropwise KH-550, raise the temperature to 130°C to modify the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com