Formaldehyde purifying type dry powder paint and preparation method thereof

A dry powder coating and formaldehyde purification technology, applied in powder coatings, coatings, etc., can solve problems such as difficult to effectively purify formaldehyde, achieve the effect of not easy to precipitate and delaminate, reduce the use of additives, and increase stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Example 1 Lanbo Bay Biotechnology, Baojian Nanotechnology, Qingdao Yanxin Technology.

[0055] Take the preparation of 100 kilograms of formaldehyde purification type dry powder coating as an example, sampling according to the quality of the following components:

[0056] 1250 mesh calcined kaolin 40kg, zinc oxide 25kg, latex powder 5kg, concave-convex powder 15kg, diatomaceous earth 5kg, redox formaldehyde scavenger 8kg (Lambo Bay Biotechnology Company), liquid metal soap defoamer 2kg.

[0057] After the raw material components are uniformly mixed according to the weight percentage, the finished product can be obtained by packaging. When painting, take an appropriate amount of powder product, add 40% of the powder mass of distilled water, stir evenly to make the powder as wet as possible, and stir evenly at a slow speed for construction.

Embodiment 2

[0059] Take the preparation of 100 kilograms of formaldehyde purification type dry powder coating as an example, sampling according to the quality of the following components:

[0060] 1650 mesh kaolin 10kg, 2000 mesh calcium carbonate 70kg, titanium dioxide 5kg, latex powder 11.9kg, uneven powder 1kg, diatomaceous earth 1kg, neutralization reaction type formaldehyde scavenger 1kg (Baojian Nano Technology Co., Ltd.), and sodium polyacrylate 0.1kg.

[0061] After the raw material components are uniformly mixed according to the weight percentage, the finished product can be obtained by packaging. When painting, take an appropriate amount of powder product, add 50% of the powder mass in distilled water, stir evenly to make the powder as wet as possible, and stir evenly at a slow speed for construction.

Embodiment 3~8

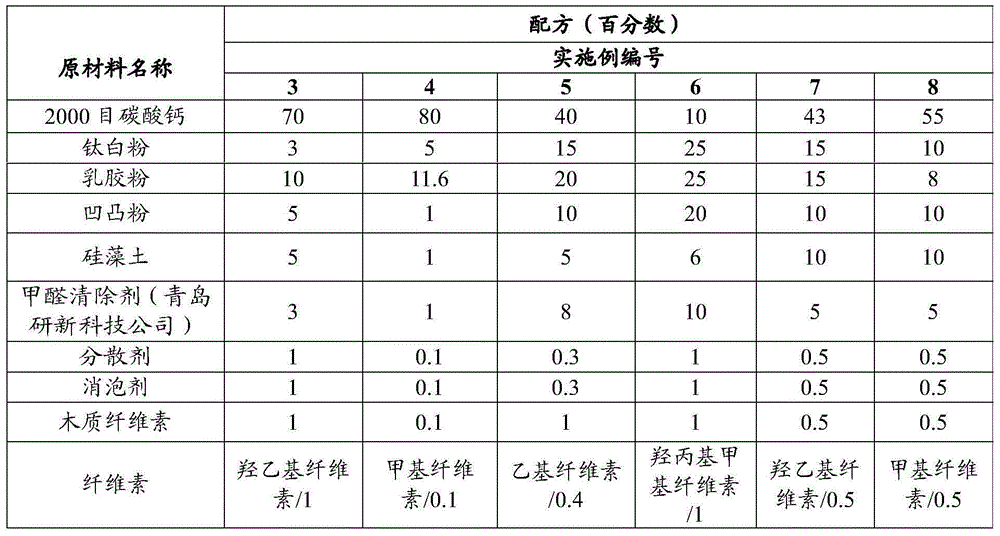

[0063] A formaldehyde purification type dry powder paint is prepared according to the weight percentage of each component of Example No. 3-8 in Table 1.

[0064] The above components are mixed, added to the powder mixing tank, stirred to make the dispersion uniform, and packaged to obtain a powder product. When painting, take an appropriate amount of powder product, add about 50% of the powder mass in distilled water, stir evenly to make the powder as wet as possible, and stir evenly at a slow speed for construction.

[0065] Table 1 Formaldehyde purification type dry powder coating formula example

[0066]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com