Multifunctional composite fracturing liquid system

A composite fracturing and multi-functional technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of complex flowback fluid composition, complex fluid mixing process, and increased difficulty in quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] The associative polymer used as a drag reducing agent is hydrophobically modified hydroxyethyl cellulose, 0.05wt%; the synergist is sodium dodecylbenzenesulfonate (sodium dodecylbenzenesulfonate), 0.2wt% ; The clay stabilizer is KCl, 1wt%.

[0076] Use a balance to weigh the water (clear water) for preparing water resistance reduction, pour it into the mixer, adjust the speed of the mixer until the middle axis at the bottom of the mixer is seen, and then slowly add the associated polymer into the mixer to ensure that the associated polymer is dispersed Evenly without agglomeration, stir for 2-3 minutes, then add synergist and clay stabilizer, and continue stirring for 1-2 minutes to obtain water resistance reduction.

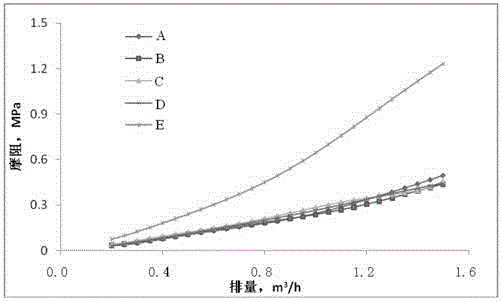

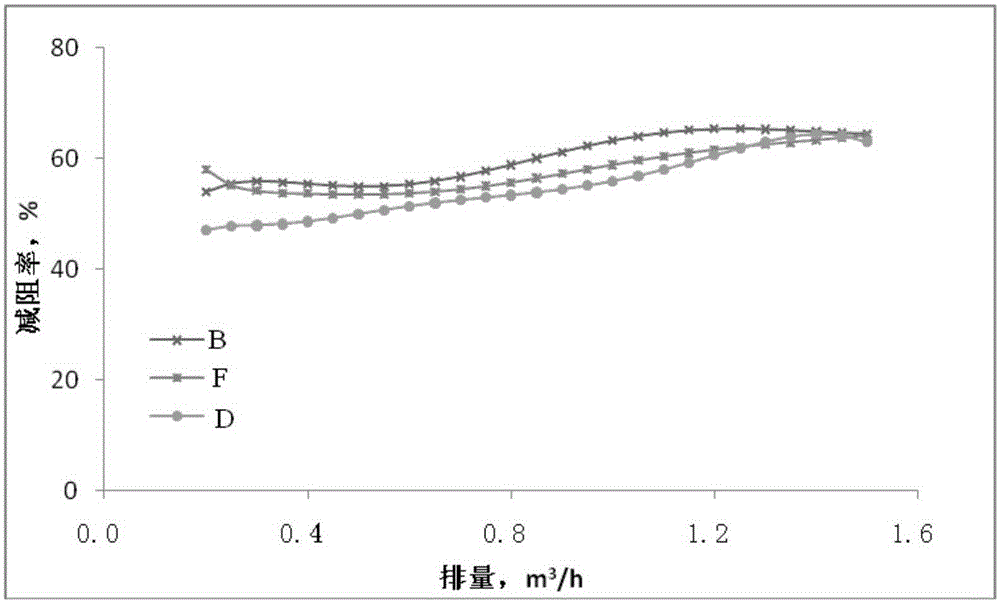

[0077] Test (25° C.) the drag-reducing water friction obtained in Example 1 to obtain a relational curve between its friction and displacement, as shown in figure 1 As shown, wherein D is the water resistance reduction obtained in Example 1. It can be s...

Embodiment 2

[0081] The associative polymer used as drag reducing agent is Sichuan Guangya Polymer Chemical Co., Ltd. associative non-crosslinked fracturing thickener GRF-1C, 0.08wt% (effective concentration of associative polymer); the synergist is GRF-2C, 0.2wt%; clay stabilizer is KCl, 1wt%.

[0082] Use a balance to weigh the water (clear water) for preparing water resistance reduction, pour it into the mixer, adjust the speed of the mixer until the middle axis at the bottom of the mixer is seen, and then slowly add the associated polymer into the mixer to ensure that the associated polymer is dispersed Evenly without agglomeration, stir for 2-3 minutes, then add synergist and clay stabilizer, and continue stirring for 1-2 minutes to obtain water resistance reduction.

[0083] Test (25° C.) the drag-reducing water friction obtained in Example 2 to obtain a relational curve between its friction and displacement, as shown in figure 1 Shown, wherein B is the water resistance reduction ob...

Embodiment 3

[0088] The associative polymer used as drag reducing agent is Sichuan Guangya Polymer Chemical Co., Ltd. associative non-crosslinked fracturing thickener GRF-1H, 0.1wt%; the synergist is GRF-2B, 0.15wt%; The clay stabilizer is KCl, 1 wt%.

[0089] Use a balance to weigh the water (clear water) for preparing water resistance reduction, pour it into the mixer, adjust the speed of the mixer until the middle axis at the bottom of the mixer is seen, and then slowly add the associated polymer into the mixer to ensure that the associated polymer is dispersed Evenly without agglomeration, stir for 2-3 minutes, then add synergist and clay stabilizer, and continue stirring for 1-2 minutes to obtain water resistance reduction.

[0090] Test (25° C.) the drag-reducing water friction obtained in Example 3 to obtain a relational curve of its friction and displacement, as shown in figure 1 As shown, wherein C is the anti-resistance water obtained in Example 3, A is 0.1wt% anionic polyacryla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com