Preparation method of rare earth Eu and Dy doped strontium magnesium silicate powder

A technology of strontium magnesium silicate and powder, which is applied in the field of materials science, can solve the problems of low solid content of silica sol, high price, and difficulty in large-scale promotion, and achieve significant technological progress, low cost, and simple equipment and processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

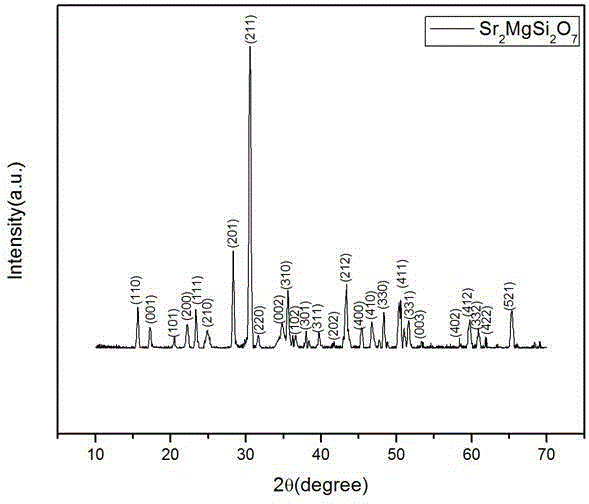

[0016] According to the molar ratio of strontium nitrate: magnesium nitrate: europium nitrate: dysprosium nitrate: sodium silicate: urea=1.97:1:0.01:0.02:1:6 ratio, strontium nitrate, magnesium nitrate, europium nitrate, dysprosium nitrate and urea Completely dissolve in deionized water, then pour into sodium silicate dissolved in water, then heat to 90°C with a magnetic stirrer, and after continuous stirring for 1 hour, move the solution directly into a high-temperature sintering furnace preheated to 850°C, With the evaporation of water, it burns violently to obtain a fluffy and foamy product, and its XRD is as follows: figure 1 As shown, it can be seen from the XRD pattern that the product is strontium magnesium silicate Sr 2 MgSiO 7 : Eu, Dy powder.

Embodiment 2

[0018] According to the molar ratio of strontium nitrate: magnesium nitrate: europium nitrate: dysprosium nitrate: sodium silicate: urea = 1.8:0.95:0.1:0.1:1:30, completely dissolve strontium nitrate, magnesium nitrate and urea in deionized water , then pour the sodium silicate dissolved in water into it, and then heat it to 100°C with a magnetic stirrer. After stirring continuously for 0.3 hours, move the solution directly into a high-temperature sintering furnace preheated to 650°C. With the evaporation of water, Combust violently to obtain a fluffy and foamy product, and all the other implementation conditions are the same as in Example 1 to obtain strontium magnesium silicate Sr 2 MgSiO 7 : Eu, Dy powder.

Embodiment 3

[0020] According to the molar ratio of strontium nitrate: magnesium nitrate: europium nitrate, dysprosium nitrate, sodium silicate: citric acid = 1.98:2:0.01:0.01:2:3, completely dissolve strontium nitrate, magnesium nitrate and citric acid in the Then pour the sodium silicate dissolved in the water into the ionized water, and then heat it to 95°C with a magnetic stirrer. After stirring continuously for 0.5 hours, move the solution directly into a high-temperature sintering furnace preheated to 700°C. Evaporate, burn violently, obtain fluffy foamy product, all the other implementation conditions are the same as embodiment 1, have obtained SrMgSiO 4 : Eu, Dy powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com