Preparation method of adsorbent for complexing heavy metals in water

A heavy metal and adsorbent technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, water pollutants, etc., can solve the problems of complex process control conditions, increased investment, limited adsorption capacity of complex heavy metal ions, etc. Rich, simple process, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

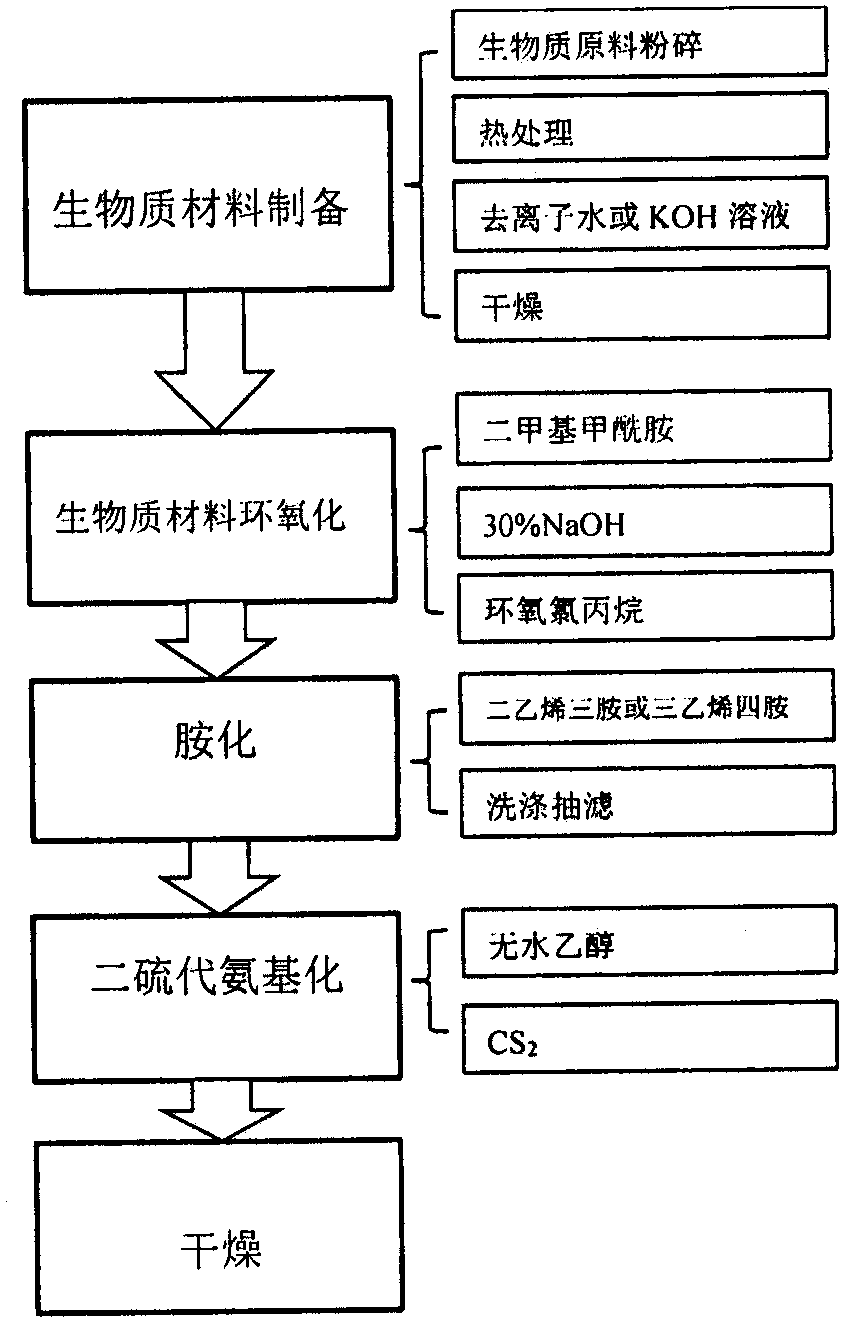

Method used

Image

Examples

Embodiment 1

[0033] Biomass material preparation: crush poplar wood chips to 60-100 meshes, heat up to 300°C at a rate of 10°C / min in a tube furnace under nitrogen protection, and keep it for 1 hour, then cool down to room temperature naturally , with 100mL of deionized strong stirring to soak the above 1g of biomass material for 2 hours, then suction filtration, and repeated washing with water for 3 times, then dried in an oven at 105°C to constant weight.

[0034] Epoxidation of biomass material: 3 g of biomass material: 20 mL of dimethylformamide: 5 mL of 30% NaOH: 15 mL of epichlorohydrin was stirred in a closed three-necked flask at 90° C. for 1 hour.

[0035] Amination: Lower the temperature in the vessel in the previous step to 40°C, slowly add 5 mL of diethylenetriamine dropwise, and stir for 1 to 5 hours. Wash and filter with appropriate amount of acetone, ethanol, and deionized water three times respectively.

[0036] Dithioamination: Add 40mL absolute ethanol, 15mL CS 2 , and ...

Embodiment 2

[0040] Biomass material preparation: crush poplar wood chips to 60-100 mesh, heat up to 500°C at a rate of 10°C / min in a tube furnace under nitrogen protection, and keep it for 2 hours, then cool down to room temperature naturally , and then soak the biomass material with 300mL of 1.5mol / L KOH solution under vigorous stirring for 2 hours, then repeatedly soak and wash with deionized water until neutral, and finally dry it in an oven at 105°C to constant weight.

[0041] Epoxidation of biomass material: 3 g of biomass material: 20 mL of dimethylformamide: 5 mL of 30% NaOH: 15 mL of epichlorohydrin was stirred in a closed three-necked flask at 90° C. for 1 hour.

[0042]Amination: Lower the temperature in the container in the previous step to 35°C, slowly drop 5 mL of diethylenetriamine into the mixture, and stir for 3 hours. Wash and filter with appropriate amount of acetone, ethanol, and deionized water three times respectively.

[0043] Dithioamination: Add 30mL absolute eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com