Biomass low-carbon diesel oil

A biomass and diesel technology, applied in the fields of biofuel, petroleum industry, liquid carbon-containing fuel, etc., to achieve the effect of easy expansion, weak sensitivity, and lower cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

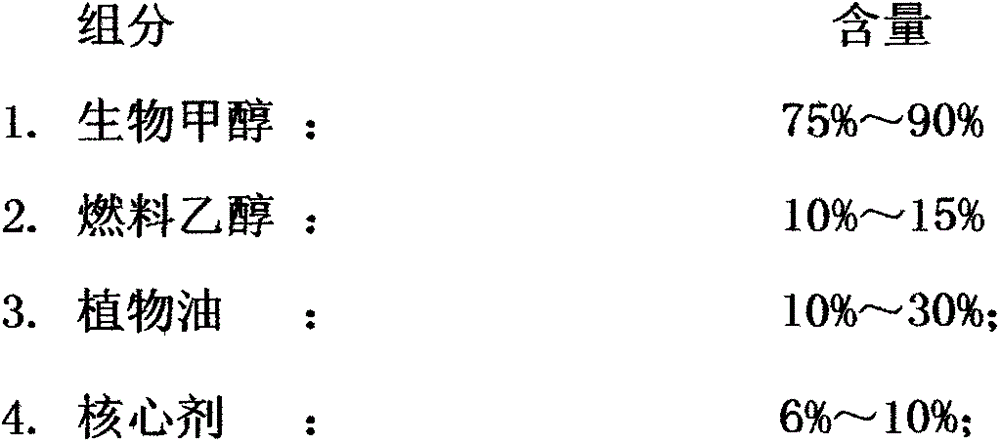

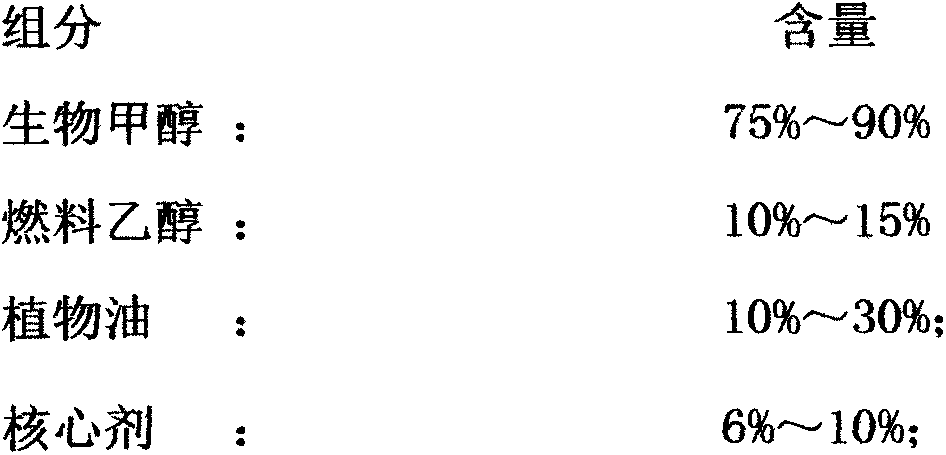

Method used

Image

Examples

Embodiment 1

[0030] The weight ratio of the core agent of this kind of biomass low-carbon diesel oil:

[0031] 2kg of fumarate, 2kg of ethyl nitrate, 1kg of 2.6-di-tert-butyl-p-cresol, 1kg of succinimide, 2kg of petroleum sulfonate, 8kg of five additives, dissolved in 2 times of bio-methanol , blended into 24kg mother liquor, weighed 6kg as the core agent.

[0032] Add 150kg of vegetable oil, 750kg of biomethanol, 6kg of core agent, and 94kg of fuel ethanol to a 1,000kg container in sequence, and mix and stir evenly under normal temperature and pressure to obtain 1,000kg of biomass low-carbon diesel oil with a calorific value of 35kJ / g.

[0033] The bench test shows that the diesel engine runs smoothly without changing the structure of the diesel engine, and there is no black smoke at the maximum throttle, and the emission fully meets the European No. 3 standard.

Embodiment 2

[0035] The weight ratio of the core agent of this kind of biomass low-carbon diesel oil:

[0036] Sodium hydroxide 2kg, alkyl nitrate 1kg, isobutanol 2kg, alkenyl succinimide 2kg, ferrocene 3kg, five kinds of additives are blended into 10kg, dissolved in 2 times of bio-methanol, blended into 30kg mother liquor , Take by weighing 8kg as the core agent.

[0037] Add 142kg of vegetable oil, 750kg of biomethanol, 8kg of core agent, and 100kg of fuel ethanol to a 1000kg container in sequence, and mix and stir evenly under normal temperature and pressure to obtain 1000kg of biomass low-carbon diesel oil with a calorific value of 34kJ / g.

[0038] Bench test result is the same as embodiment 1.

Embodiment 3

[0040] The weight ratio of the core agent of this kind of biomass low-carbon diesel oil:

[0041] Fumarate 1kg, sodium hydroxide 1kg, ethyl nitrate 1kg, alkyl nitrate 1kg, 2.6-di-tert-butyl p-cresol 1kg, isobutanol 1kg, succinimide 1kg, alkenyl butanedi 1kg of imide, 1kg of petroleum sulfonate, 1kg of ferrocene, and ten kinds of additives were blended into 10kg, dissolved in 2 times biomethanol, blended into 30kg of mother liquor, and the weight of 10kg was weighed as the core agent.

[0042] Add 60kg of vegetable oil and 900kg of biomethanol, 10kg of core agent, and 30kg of fuel ethanol in a 1000kg container in sequence, and mix and stir evenly under normal temperature and pressure to obtain 1000kg of biomass low-carbon diesel oil with a calorific value of 35kJ / g.

[0043] Bench test result is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com