Spray gun used for desulphurizing by directly spraying and blowing magnesium desulfurizing agent to molten iron

A technology of hot metal desulfurization and magnesium desulfurization agent, applied in the field of hot metal pretreatment, can solve the problems of short service life, high bonding strength of blockages, poor fluidity, etc., to ensure integrity and air tightness, and improve air bubble penetration , Improve the effect of slag breaking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

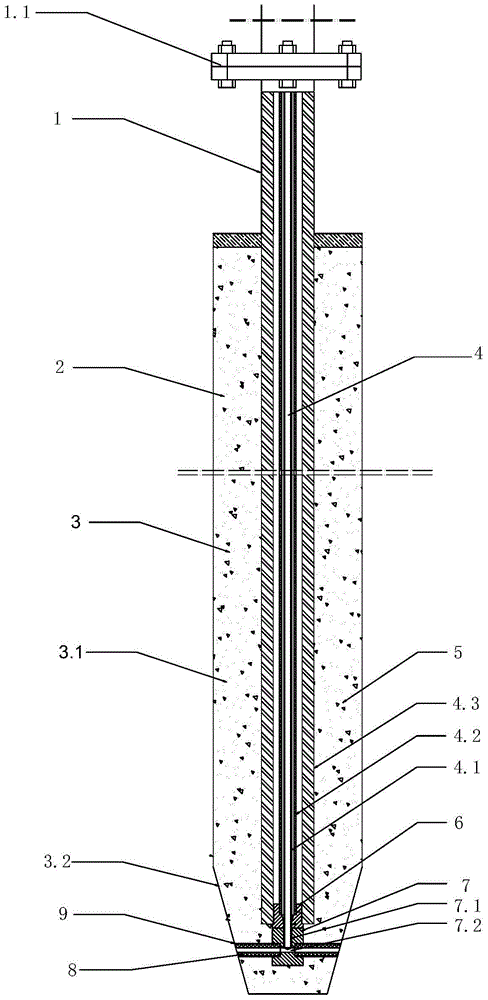

[0027] Such as figure 1 As shown, a desulfurization spray gun for direct injection of molten iron by magnesium desulfurizer is composed of connecting section 1, gun body section 2 and injection section 3, connecting section 1 is sequentially composed of connecting flange 1.1 and composite gun core 4, the gun The outer wall of the body 2 and the injection section 3 is made of refractory material lining and poured into the gun wall 5; it is characterized in that: the injection section 3 includes the injection section gun body 3.1 and the special-shaped gun head 3.2 arranged on the top of the injection section gun body 3.1 , the composite gun core 4 runs through the entire gun body section 2 and the injection section gun body 3.1 and extends into the middle of the special-shaped gun head 3.2; the shape of the special-shaped gun head 3.2 is rounded;

[0028] The composite gun core 4 includes an inner intubation tube 4.1, a main pipe 4.2 and a reinforcing tube 4.3 from the inside t...

Embodiment 2

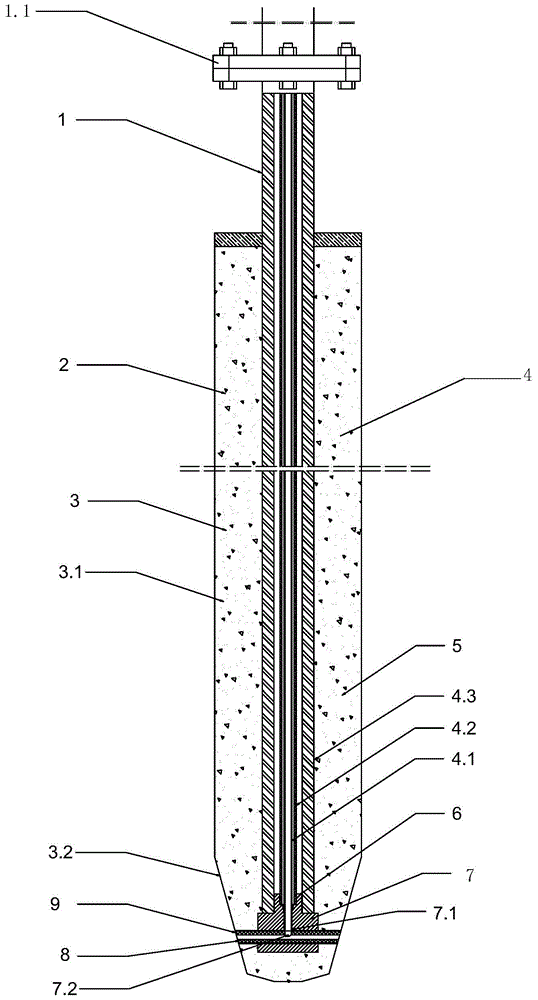

[0037] Such as figure 2 Shown, the structure of the spray gun of the present embodiment is basically the same as that of embodiment 1, the difference is:

[0038] The shape of the special-shaped gun head 3.2 is a combined structure of an inverted spherical crown and an inverted round table; the spray pipe connector 7 and the inner cannula connector 6 are integrally processed and fixed on the outer wall of the bottom of the reinforcing pipe 4.3.

[0039] The radial horizontal channel 7.2 is a horizontal straight through hole, and a single graphite injection pipe 8 is arranged in the radial horizontal channel 7.2, half of the graphite injection pipe 8 is wrapped in the radial horizontal channel 7.2 and the graphite injection pipe 8 is parallel to the radial horizontal channel 7.2. The channel 7.2 is coaxial; the diameter of the radial horizontal channel 7.2 is 1-2 mm larger than the outer diameter of the inner tube 8 of the spray gun, and the inner hole area of the graphite s...

Embodiment 3

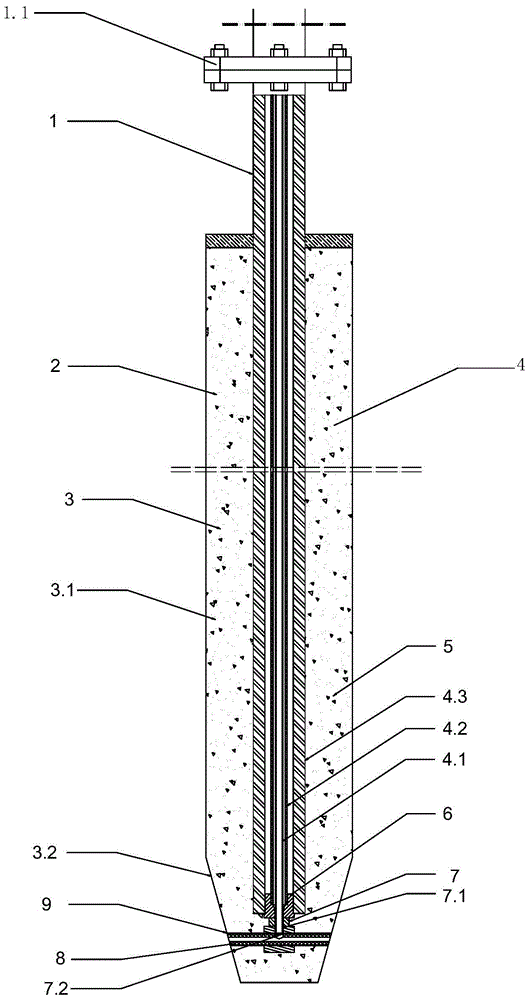

[0041] Such as image 3 Shown, the structure of the spray gun of the present embodiment is basically the same as that of embodiment 1, the difference is:

[0042] The blowing pipe connector 7 is an inverted T-shaped structure formed by connecting the vertical round pipe and the horizontal round pipe. Straight-through hole, a single graphite blowing pipe 8 is arranged in the radial horizontal passage 7.2, and the graphite blowing pipe 8 is coaxial with the radial horizontal passage 7.2; the diameter of the radial horizontal passage 7.2 is larger than the outer diameter of the inner insertion pipe 8 of the spray gun 1-2 mm, the area of the inner hole of the graphite blowing pipe 8 is 1 / 2 of the inner hole area of the inner insertion tube. The two ends of the graphite blowing pipe 8 extend into the installation holes 9 of the graphite blowing pipe respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com