Method for extracting manganese metal from vanadium precipitation wastewater and vanadium extraction tailings

A technology for extracting vanadium tailings and vanadium-precipitated wastewater, which is applied to the improvement of process efficiency, photography technology, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

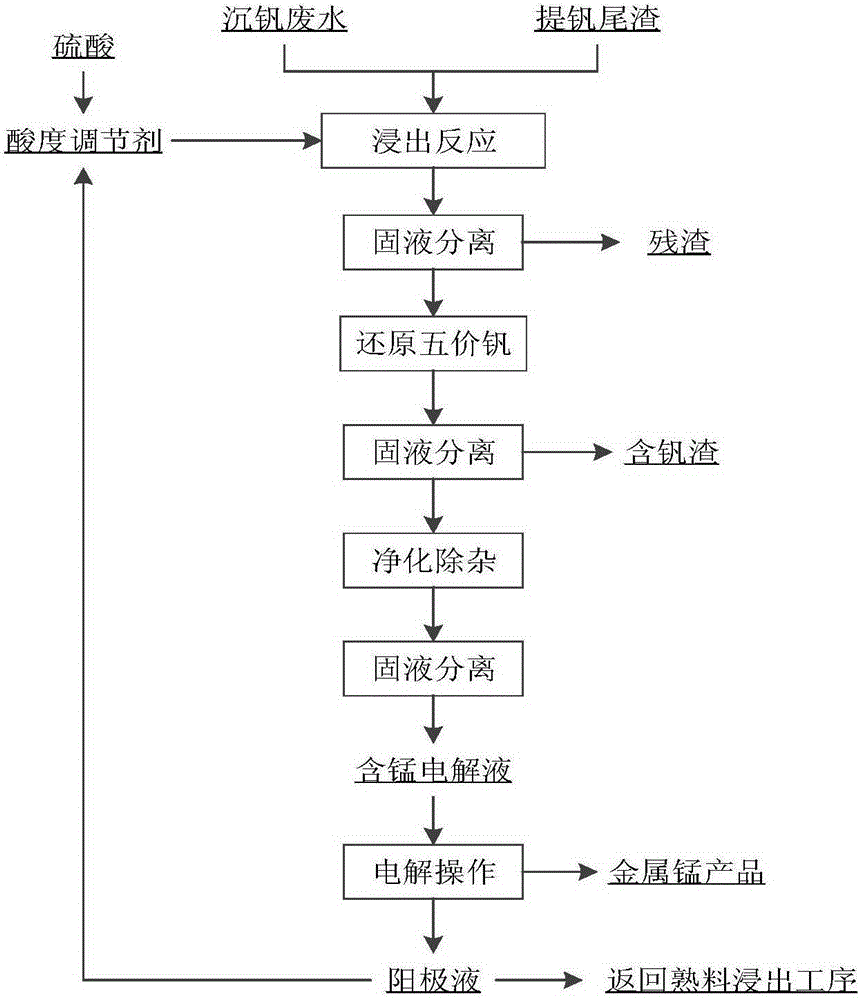

Image

Examples

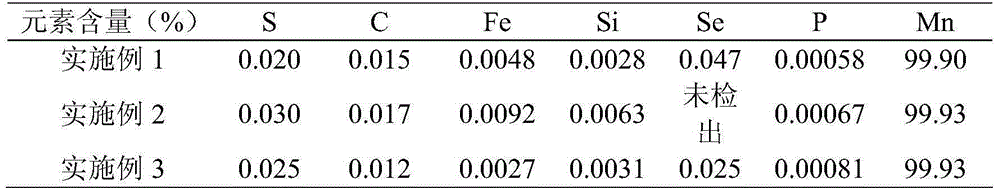

Embodiment 1

[0039] Take 5000mL of vanadium precipitation wastewater (containing manganese 10.20g / L, vanadium 0.25g / L, pH=1.5), add vanadium extraction tailings 5000g (containing manganese 4.82%, vanadium 1.24%), start stirring, and use acidity regulator ([ h + ]=1mol / L) to adjust the acidity of the system to 2.5, heated to 80°C in a water bath, filtered after stirring for 2h to obtain the first filtrate (containing manganese 12.30g / L, vanadium 0.39g / L) and residue (containing manganese 2.58%, vanadium 1.03%); in the first filtrate, add ferrous sulfate 3.0g / L in the first filtrate, stir and react at 70°C for 80min, use ammonia water to adjust pH to 6.0 after the reaction is completed, and carry out solid-liquid separation to obtain the second filtrate and vanadium-containing Slag (in V 2 o 5 Calculated as 16.2%); add manganese dioxide solid 2g / L second filtrate to the second filtrate, feed air, react at 60°C for 1.5h; use ammonia water to adjust pH to 7.0, add activated carbon 1.0g / L sec...

Embodiment 2

[0041] Take 5000mL of vanadium precipitation wastewater (containing manganese 8.30g / L, vanadium 0.20g / L, pH=2.0), add vanadium extraction tailings 7500g (containing manganese 4.82%, vanadium 1.24%), start stirring, and use acidity regulator ([ h + ]=2mol / L) to adjust the acidity of the system to 1.5, heated to 70°C in a water bath, stirred and reacted for 1.5h and filtered to obtain the first filtrate (containing manganese 12.20g / L, vanadium 0.61g / L) and residue (containing manganese 2.05%, Vanadium 0.92%); In the first filtrate, adding mass concentration is 6% sulfurous acid 9.0mL / L first filtrate (that is, 9ml sulfurous acid is added in the first 1L filtrate), stirred and reacted 40min under 60 ℃, after the completion of the reaction, use Ammoniacal liquor adjusts pH to 6.0, carries out solid-liquid separation and obtains the second filtrate and vanadium-containing slag (with V 2 o 5Calculated as 24.4%); feed air into the second filtrate, and react for 1h at 60°C; adjust t...

Embodiment 3

[0043] Take 5000mL of vanadium precipitation wastewater (containing manganese 14.50g / L, vanadium 0.30g / L, pH=2.5), add vanadium extraction tailings 6000g (containing manganese 5.74%, vanadium 1.42%), start stirring, and use an acidity regulator ([ h + ]=2mol / L) to adjust the acidity of the system to 2.0, heated to 60°C in a water bath, filtered after stirring for 3h to obtain the first filtrate (containing manganese 18.20g / L, vanadium 0.56g / L) and residue (containing manganese 2.30%, vanadium 1.11%); in the first filtrate, add 2.5g / L of iron filings (metal iron content in the iron filings is greater than 80%), stir and react at 70°C for 80min, adjust the pH to 6.5 with ammonia water after the reaction is completed, and carry out solid-liquid separation to obtain The second filtrate and vanadium-containing slag (in V 2 o 5 Calculated as 20.6%); in the second filtrate, add manganese dioxide solid 1.5g / L second filtrate, pass into air, react at 60°C for 1.0h; use ammonia water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com