Self-adaptive fiber used in Z-pinch wire-array loads and preparing method thereof

A self-adaptive, fiber technology, applied in the direction of one-component polyurethane rayon filament, can solve the problem that self-adaptive technology cannot complete the assembly process, and achieve the effect of high resilience, high resilience and high dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

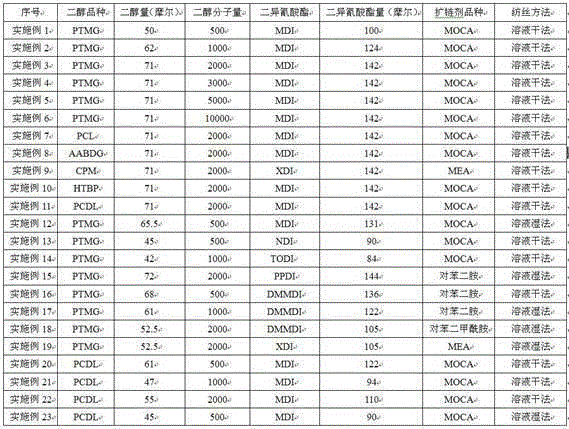

Examples

Embodiment 1

[0024] Add 50 moles of polytetrahydrofuran glycol (PTMG) with a molecular weight of 500 into a reaction kettle equipped with a stirrer, a thermometer, a vacuum system and an electric heating mantle, raise the temperature to 105°C, and dehydrate for 2 hours under high vacuum until the water content is low 0.05%, then cooled to 60°C, released the vacuum, added 100 moles of diphenylmethane diisocyanate (MDI), and kept the temperature at 80°C for 2 hours. After defoaming, the prepolymer is obtained. Use 50 moles of 3,3'-dichloro-4,4'diaminodiphenylmethane (MOCA) to carry out chain extension reaction with the prepolymer, and then choose the solution dry method to carry out the spinning forming process.

Embodiment 2

[0026] Add 62 moles of polytetrahydrofuran glycol (PTMG) with a molecular weight of 1000 into a reaction kettle equipped with a stirrer, a thermometer, a vacuum system and an electric heating mantle, raise the temperature to 105°C, and dehydrate for 2 hours under high vacuum until the water content is low 0.05%, then cooled to 60°C, released the vacuum, added 124 moles of diphenylmethane diisocyanate (MDI), and kept the temperature at 80°C for 2 hours. After defoaming, the prepolymer is obtained. Use 62 moles of chain extender 3,3′-dichloro-4,4′diaminodiphenylmethane (MOCA) to carry out chain extension reaction with prepolymer, and then choose solution dry method for spinning forming processing.

Embodiment 3

[0028] Add 71 moles of polytetrahydrofuran glycol (PTMG) with a molecular weight of 2000 into a reaction kettle equipped with a stirrer, a thermometer, a vacuum system and an electric heating mantle, raise the temperature to 105°C, and dehydrate for 2 hours under high vacuum until the water content is low 0.05%, then cooled to 60°C, released the vacuum, added 142 moles of diphenylmethane diisocyanate (MDI), and kept the temperature at 80°C for 2 hours. After defoaming, the prepolymer is obtained. Use 71 moles of chain extender 3,3′-dichloro-4,4′diaminodiphenylmethane (MOCA) to carry out chain extension reaction with prepolymer, and then choose solution dry method to carry out spinning forming process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com