Novel acid dye color fixing agent as well as preparation method and application method thereof

A technology of acid dyes and color-fixing agents, which can be used in dyeing, textiles, and papermaking. It can solve the problems of waste products, color-fixing agent spots, and defective products, and achieve the effects of simple production process, good effect, and low formaldehyde content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

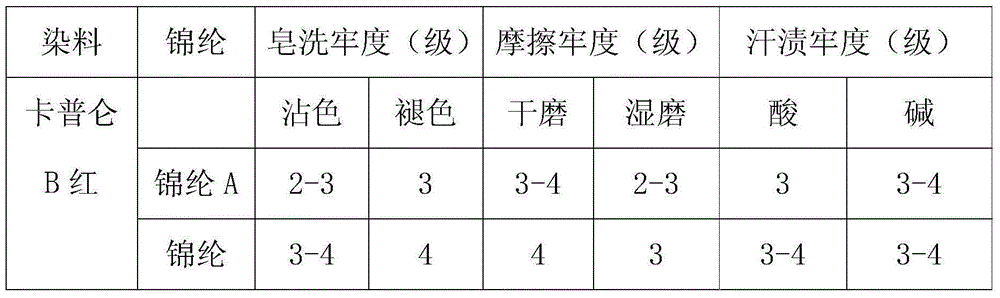

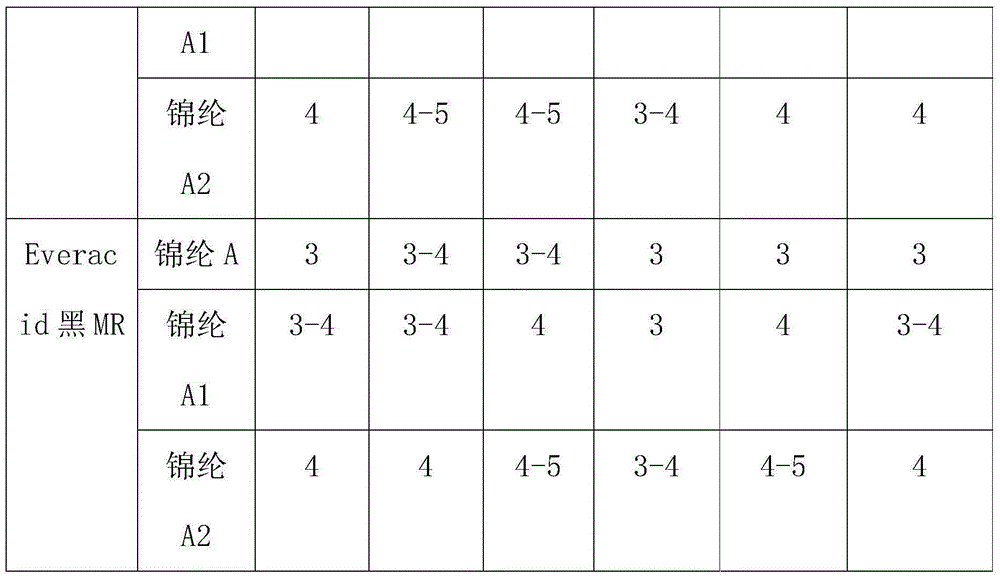

Image

Examples

Embodiment 1

[0021] Using bisphenol A, 2-naphthol, formaldehyde, etc. as main raw materials, using sodium sulfite, dehydration condensation reaction between phenols and formaldehyde molecules, and sulfonation reaction of benzene ring of phenolic substances, synthesized in aqueous solution containing sulfonic acid group The fixing agent SBNF.

[0022] Its synthetic steps are:

[0023] (1) Synthesis of Intermediate I: Add 4.56g of bisphenol A into a 250mL four-neck flask with stirring device, condenser and separatory funnel, add 30g of ethanol, 50g of water, 2.40g of formaldehyde and 3.2g of sodium sulfite in turn, and stir Raise the temperature to 80°C, and keep it warm for about 4 hours until the pH of the solution does not change;

[0024] (2) Synthesis of Intermediate II

[0025] Add 20g of concentrated sulfuric acid into a 250mL four-neck flask, add 7.20g of naphthol at 90°C, raise the temperature to 115°C, react for 3 hours, then add 10g of concentrated sulfuric acid, and react for 3...

Embodiment 2

[0029] The same as in Example 1, the difference is that the amount of each component in the step (2) is increased by 0.5 times, and the obtained intermediate II and the intermediate I in the embodiment 1 are processed according to the step (3) to obtain the product B.

Embodiment 3

[0031] Same as Example 1, the difference is: the dosage of each component in the step (2) is doubled, and the obtained intermediate II and the intermediate I in the embodiment 1 are processed according to the step (3) to obtain the product C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com