Packaging structure and packaging technology of high-voltage and high-power silicon carbide diodes

A silicon carbide diode and packaging structure technology, which is applied to semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve the problems of low chip welding reliability, large leakage of plastic packaging, and low dissipation loss, etc. Long-term reliability, low line loss, and effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described and limited below in conjunction with the accompanying drawings and specific embodiments.

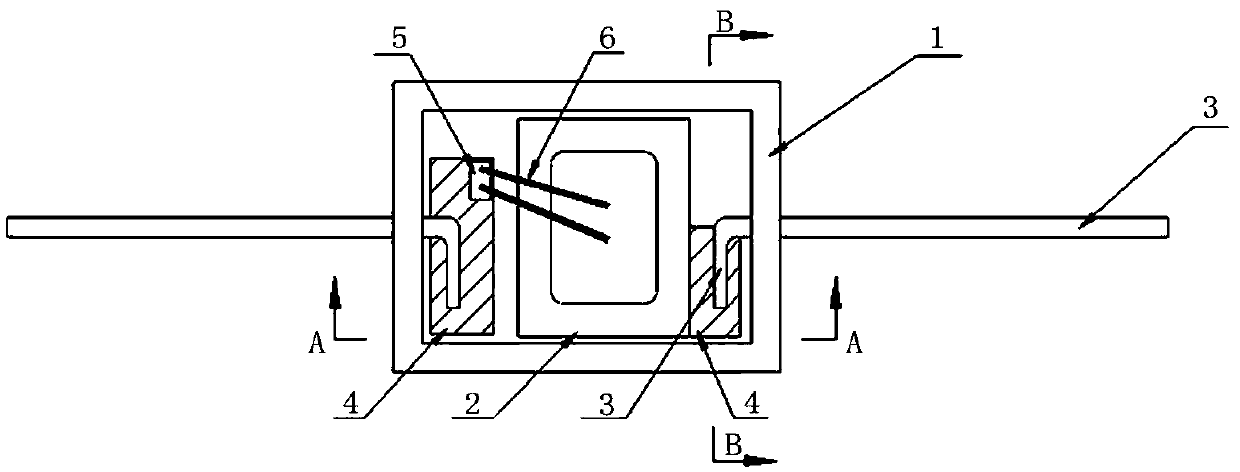

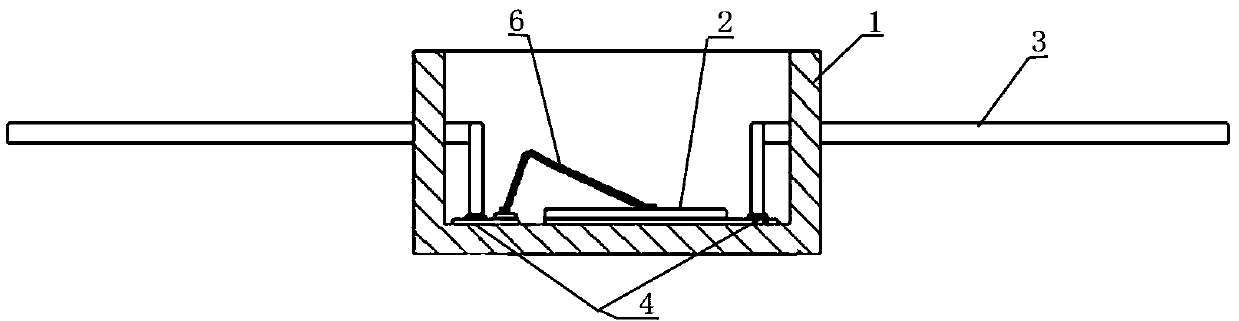

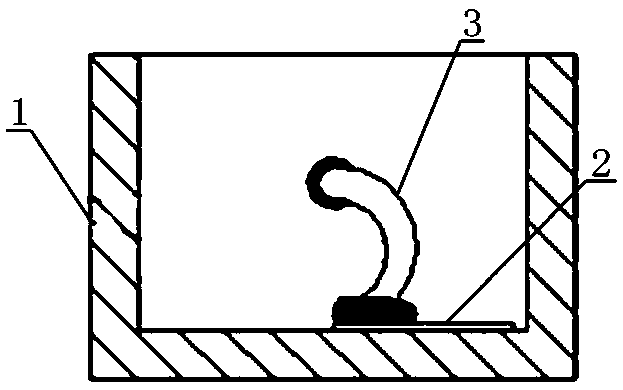

[0022] like figure 1 , 2 , 3, a high-voltage and high-power silicon carbide diode packaging structure, including a casing 1, a chip 2 located in the casing 1, and leads 3 connected to both ends of the casing 1, the casing 1 is a ceramic casing, and the chip 2 is welded to the ceramic casing. On the inner bottom surface of the casing 1, a conducting strip 4 is provided on both sides of the chip 2. The leads 3 at both ends of the casing are welded on the conducting strip 4. One of the conducting strips 4 is welded with a transition piece 5, and the transition piece 5 and the chip electrode are connected. The electrical connection is completed through the bonding wire 6.

[0023] In this embodiment, the casing 1 is a rectangular parallelepiped ceramic casing, and the chip 2 is directly welded to the inner bottom surface of the cerami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com