Application of hydrophilic-modified porous diaphragm in flow battery

A porous diaphragm and flow battery technology, applied in the field of hydrophilic modified porous diaphragm, can solve the problem of reducing the pore size, achieve the effect of improving ion selectivity, easy mass production, and realizing controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

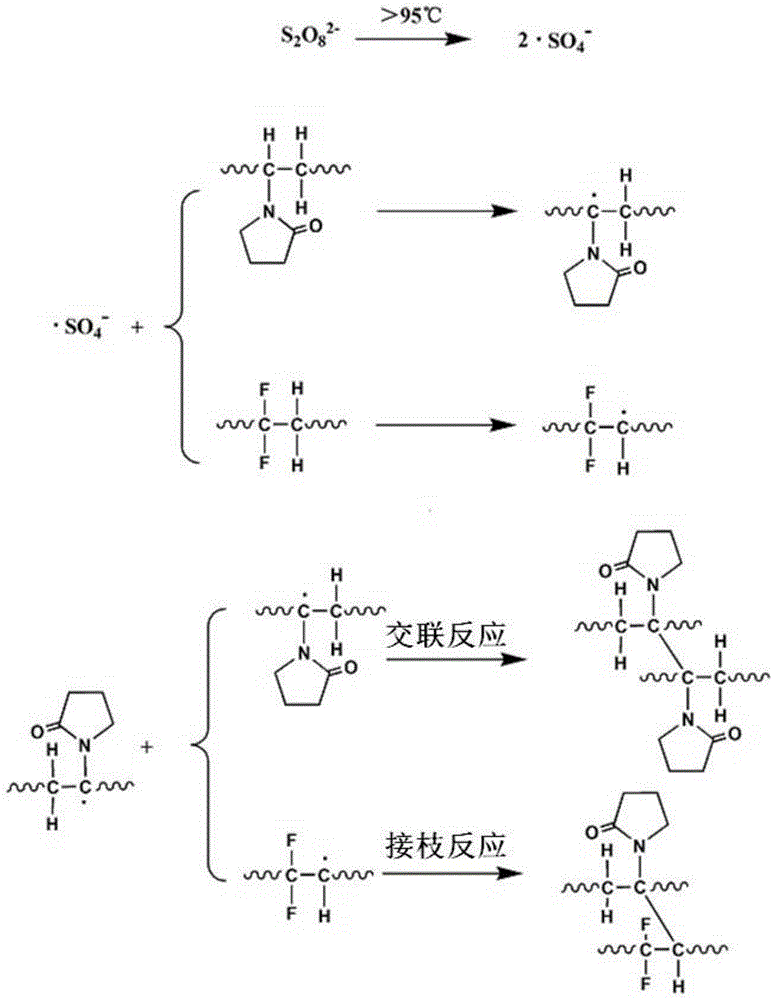

Method used

Image

Examples

Embodiment 1

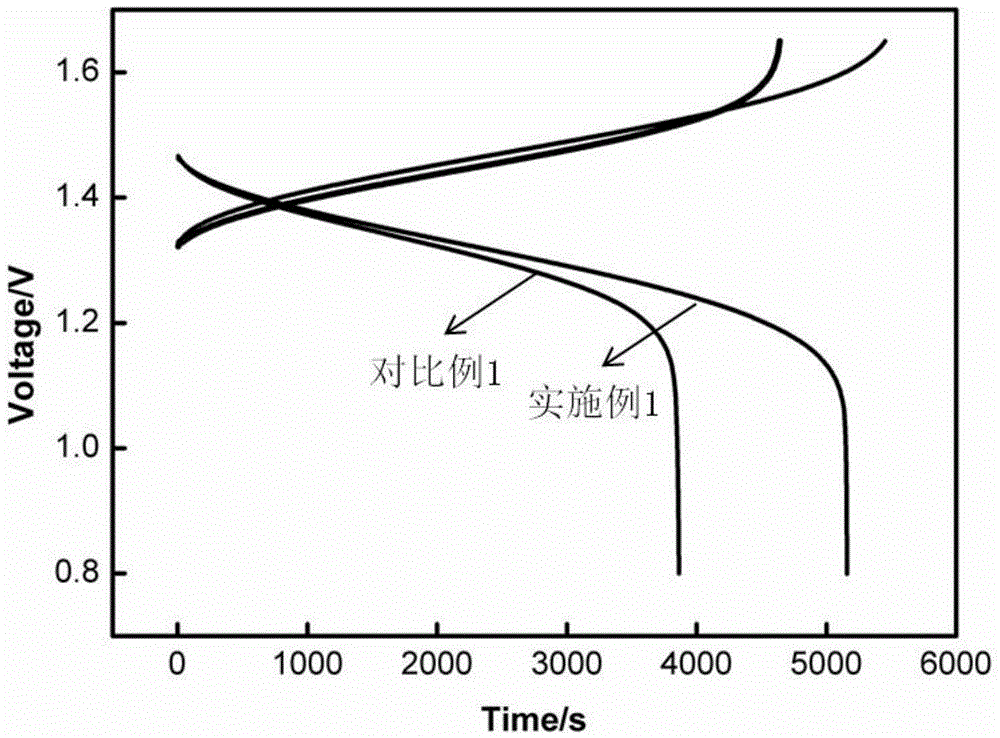

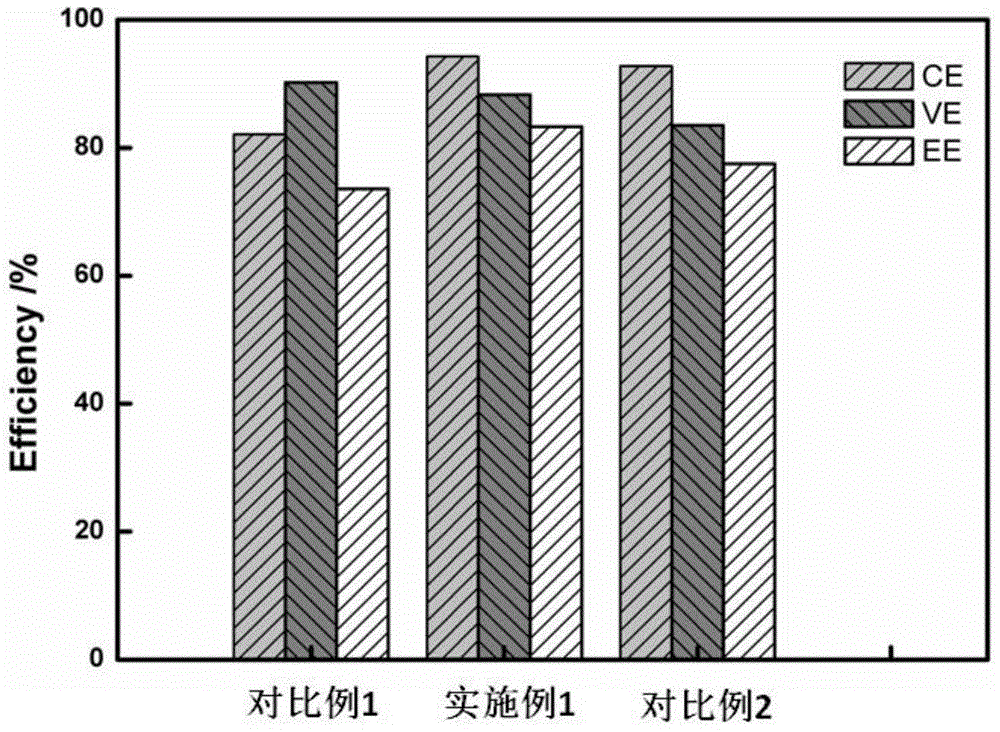

[0043]Dissolve 7.5g of polyvinylidene fluoride powder in 34g of dimethylacetamide to form a uniform transparent solution, use water as a coagulation bath, use an automatic coating machine to scrape coat, control the film thickness at about 120um, put the prepared PVDF film Store in water for later use. Before the modification reaction, soak the membrane in ethanol for 2 hours to fully swell the membrane. The specific modification process is as follows: the membrane is immersed in the prepared 4wt% PVP / 0.4wt% K2S2O8 aqueous solution for 2 hours, and the membrane pores and The ethanol on the surface of the membrane is replaced, and then the membrane is put into a container of PVP reaction solution (4wt% PVP) and sealed, and the oil bath is heated to 96° C., and the PVP is cross-linked and grafted on the PVDF membrane at high temperature. The reaction time was controlled to be 2h, and the modified PVDF membrane was obtained. After the reaction, the membrane was taken out and boi...

Embodiment 2

[0049] Embodiment 2: other conditions are the same as embodiment 1, and the swelling agent is changed to methanol.

Embodiment 3

[0050] Embodiment 3: other conditions are the same as embodiment 1, and the swelling agent is changed into isopropanol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Effective area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com