A kind of magnesia-iron-aluminum spinel kiln mouth prefabricated part

A technology of magnesium-iron-aluminum spinel and iron-aluminum spinel, which is applied in the field of magnesium-iron-aluminum spinel kiln mouth prefabrication, can solve problems such as short service life of the kiln mouth, castable segregation, castable shedding, etc. Achieve good economic benefits and market application prospects, improve high temperature stability, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

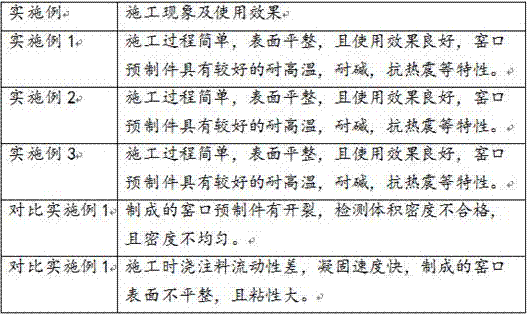

Examples

Embodiment 1

[0039] A magnesia-iron-aluminum spinel kiln mouth prefabricated part, the preparation method is as follows:

[0040] (1) Weigh each component according to formula 1, add them into the stirring device and stir evenly to obtain the mixing material A;

[0041] (2) Add a dispersant and water to the mixing material A in the step (1), and control the amount of water according to the flow value of the overall mixing material to obtain the mixing material B;

[0042] (3) Add the mixture B in the step (2) into the mold for making the kiln mouth prefabricated part, and automatically level it until the surface is smooth, and obtain the sample kiln mouth prefabricated part;

[0043] (4) Place the sample kiln mouth prefabricated part and the mold in the step (3) in the air, let it stand for 48 hours, and then perform demoulding treatment to obtain the kiln mouth prefabricated part 1;

[0044] (5) The kiln mouth prefabricated part 1 mentioned in the step (4) is naturally cured for 72 hours...

Embodiment 2

[0047] A magnesia-iron-aluminum spinel kiln mouth prefabricated part, the preparation method is as follows:

[0048] (1) Weigh each component according to formula 2, add them into the stirring device and stir evenly to obtain the mixing material A;

[0049] (2) Add a dispersant and water to the mixing material A in the step (1), and control the amount of water according to the flow value of the overall mixing material to obtain the mixing material B;

[0050] (3) Add the mixture B in the step (2) into the mold for making the kiln mouth prefabricated part, and automatically level it until the surface is smooth, and obtain the sample kiln mouth prefabricated part;

[0051] (4) Place the sample kiln mouth prefabricated part and the mold in the step (3) in the air, let it stand for 40 hours, and then perform demoulding treatment to obtain the kiln mouth prefabricated part 1;

[0052] (5) The kiln mouth prefabricated part 1 mentioned in the step (4) is naturally cured for 56 hours...

Embodiment 3

[0055] A magnesia-iron-aluminum spinel kiln mouth prefabricated part, the preparation method is as follows:

[0056] (1) Weigh each component according to Formula 3, add them into the stirring device and stir evenly to obtain the mixing material A;

[0057] (2) Add a dispersant and water to the mixing material A in the step (1), and control the amount of water according to the flow value of the overall mixing material to obtain the mixing material B;

[0058] (3) Add the mixture B in the step (2) into the mold for making the kiln mouth prefabricated part, and automatically level it until the surface is smooth, and obtain the sample kiln mouth prefabricated part;

[0059] (4) Place the sample kiln mouth prefabricated part and the mold in the step (3) in the air, let it stand for 36 hours, and then perform demoulding treatment to obtain the kiln mouth prefabricated part 1;

[0060] (5) Prefabricated kiln mouth prefabricated part 1 described in step (4) is naturally maintained f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com