Controlled-release fertilizer for sugarcane and preparation method thereof

A controlled-release fertilizer and sugarcane technology, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of poor controlled-release effect of fertilizers and low fertilizer utilization efficiency, and achieve improved encapsulation efficiency, water use efficiency, and controlled release. Moderate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

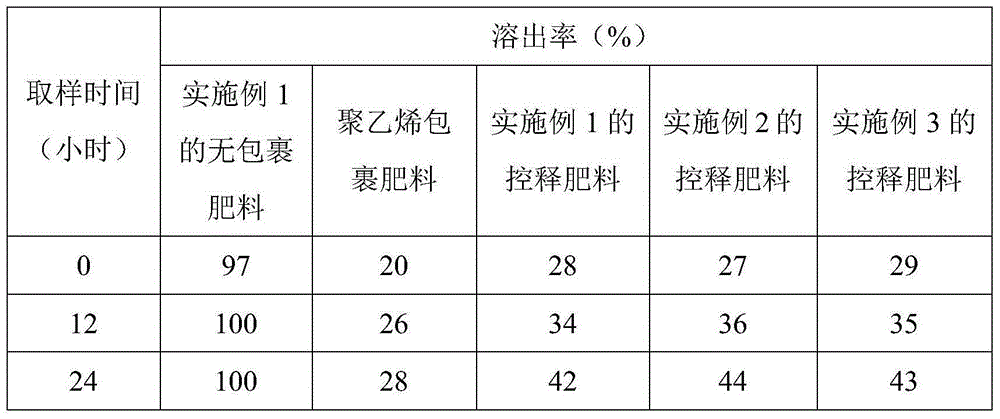

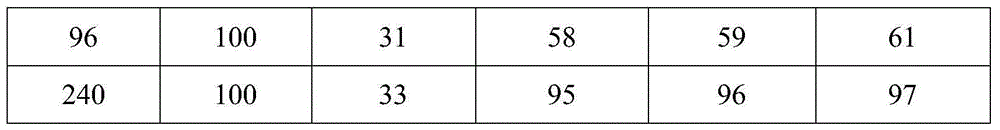

Examples

Embodiment 1

[0030] A sugarcane controlled-release fertilizer, in parts by weight, comprising the following raw materials: 60 parts of wrapping materials, 1200 parts of fertilizer granules;

[0031] The wrapping material includes the following raw materials in parts by weight: 50 parts of fat, 3 parts of ammonium bicarbonate, 3 parts of calcium phosphate, 3 parts of potassium chloride, 0.2 part of potassium borate, 0.2 part of ferrous sulfate, 0.2 part of zinc chloride 0.2 part, 0.2 part of manganese glycinate, and 0.2 part of copper glycinate, and the fat is processed and made from oil leftovers;

[0032] The fertilizer granules are in parts by weight and include the following raw materials: 270 parts of urea, 250 parts of diammonium phosphate, 200 parts of potassium chloride, 60 parts of calcium hydrogen phosphate dihydrate, 58 parts of magnesium borate, 8 parts of zinc glycinate, iron glycinate 8 parts, manganese glycinate 8 parts, copper sulfate 8 parts, fulvic acid 300 parts, polyacry...

Embodiment 2

[0037] A sugarcane controlled-release fertilizer, in parts by weight, comprising the following raw materials: 140 parts of wrapping materials, 180 parts of fertilizer granules;

[0038] The wrapping material includes the following raw materials in parts by weight: 120 parts of fat, 6 parts of ammonium bicarbonate, 6 parts of calcium phosphate, 6 parts of potassium chloride, 0.4 part of potassium borate, 0.4 part of ferrous sulfate, 0.4 part of zinc chloride 0.4 part, 0.4 part of manganese glycinate, 0.4 part of copper glycinate, and described fat is processed and formed by the leftovers of oil;

[0039] The fertilizer granules are in parts by weight and include the following raw materials: 40 parts of urea, 40 parts of diammonium phosphate, 30 parts of potassium chloride, 12 parts of calcium hydrogen phosphate dihydrate, 10 parts of magnesium borate, 2 parts of zinc glycinate, iron glycinate 2 parts, manganese glycinate 2 parts, copper sulfate 2 parts, fulvic acid 30 parts, po...

Embodiment 3

[0044] A controlled-release fertilizer for sugarcane, comprising the following raw materials in parts by weight: 100 parts of wrapping material, 700 parts of fertilizer granules;

[0045] The wrapping material includes the following raw materials in parts by weight: 85 parts of fat, 5 parts of ammonium bicarbonate, 4.5 parts of calcium phosphate, 4 parts of potassium chloride, 0.3 part of potassium borate, 0.3 part of ferrous sulfate, 0.3 part of zinc chloride 0.3 part, 0.3 part of manganese glycinate, 0.3 part of copper glycinate;

[0046]The fertilizer granules are in parts by weight and include the following raw materials: 150 parts of urea, 150 parts of diammonium phosphate, 115 parts of potassium chloride, 36 parts of calcium hydrogen phosphate dihydrate, 34 parts of magnesium borate, 5 parts of zinc glycinate, iron glycinate 5 parts, manganese glycinate 5 parts, copper sulfate 5 parts, fulvic acid 175 parts, polyacrylamide 5 parts, potassium polyacrylate 5 parts, bentoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com