Antibacterial and corrosion-resistant nano-composite coating strongly combined with implant and preparation method thereof

A nano-composite coating and implant technology, applied in the direction of coating, metal material coating process, prosthesis, etc., can solve the problems of easy to cause drug resistance, limited antibiotic action time, etc., and achieve strong activity and moderate release speed. , good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

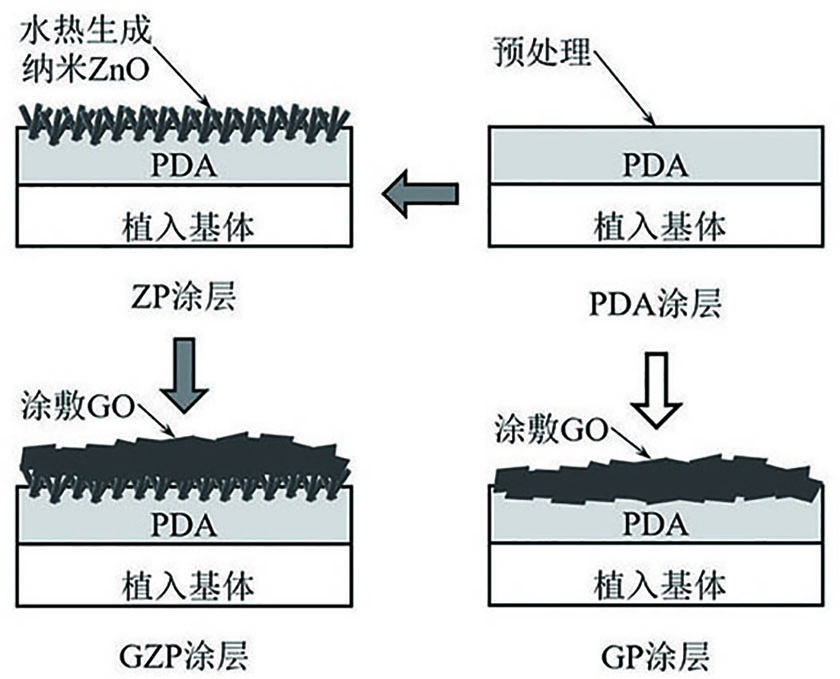

[0020] The preparation method of the nano-composite coating with strong combination with the implant body and antibacterial and corrosion resistance of the present invention comprises the following steps:

[0021] Step (1) preparing a PDA coating on the surface of the implant;

[0022] Step (2) Prepare a GO coating on the surface of the implant obtained in step (1), and obtain a polydopamine-graphene oxide nanocomposite coating that is strongly combined with the implant and has antibacterial and corrosion resistance properties, that is, GP nanocomposite coating;

[0023] Step (3) Prepare a nano-ZnO coating on the surface of the implant obtained in step (1), and obtain a polydopamine-nano-zinc oxide nanocomposite coating that is strongly combined with the implant and has antibacterial and corrosion resistance properties, that is, ZP nano Composite coating;

[0024] Step (4) Prepare a GO coating on the surface of the implant obtained in step (3), and obtain a polydopamine-nano...

Embodiment 1

[0089] Nanocomposite coating of the present invention, the flow chart of its preparation method is as figure 1 As shown, the details are as follows:

[0090] (1) Use the polished titanium alloy (Ti6Al4V) as the substrate, and ultrasonically clean it in acetone, absolute ethanol, and deionized water for 15 minutes;

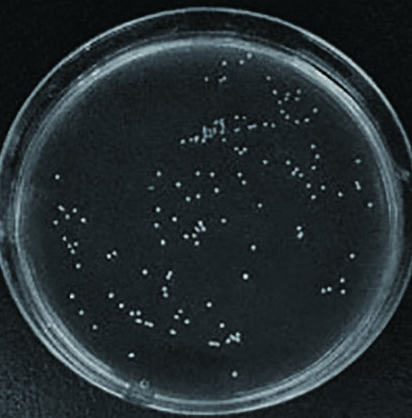

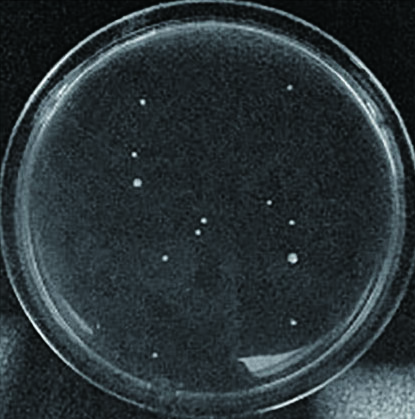

[0091] (2) Prepare a PDA coating on the surface of the titanium alloy substrate obtained in step (1) by a solution oxidation method. The dosage of trishydroxyaminomethane hydrochloride is 0.0788g, the dosage of dopamine hydrochloride is 0.1000g, and the pH value of the solution environment is 8.5, the reaction temperature is 25°C, the thickness of the PDA layer is 50nm; see the antibacterial effect of the PDA coating figure 2 ; Corrosion resistance see Figure 7~Figure 12 shown.

[0092] (3) On the surface of the PDA coating obtained in step (2), GO powder was prepared by using the improved Hummers method and freeze-drying treatment. First, the product obtained...

Embodiment 2

[0096] Nanocomposite coating of the present invention, the flow chart of its preparation method is as figure 1 As shown, the details are as follows:

[0097] (1) Use the polished titanium alloy (Ti6Al4V) as the substrate, and ultrasonically clean it in acetone, absolute ethanol, and deionized water for 15 minutes;

[0098] (2) adopt and embodiment 1 identical mode to prepare PDA coating;

[0099] (3) On the surface of the PDA coating obtained in step (2), a nano-ZnO coating was prepared by a seedless hydrothermal method, and 0.2975g Zn(NO 3 ) 2 ·6H 2 O and 0.1402g of hexamethylenetetramine (HMT) powder were respectively dissolved in 100mL of deionized water to form a solution with a concentration of 0.01mol / L;

[0100] (4) The solution obtained in step (3) was poured into Zn(NO 3 ) 2 Stir and mix the solution evenly, then put it into the titanium alloy substrate coated with PDA coating, and then rapidly raise the temperature to the preset temperature of 90°C. As the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com