Preparation method of three-dimensional super-molecule framework coordination polymer

A technology of coordination polymers and supramolecules, applied in the field of material chemistry, to achieve good crystallinity, high chemical stability, and good product crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Preparation of the target framework coordination polymer: at room temperature, first mix 0.023g CoCl 2 ·6H 2 5 mL of deionized aqueous solution of O was added to 0.024 g of 1,4-bis(1H-1,2,4-triazole-methylene)benzene (bbtz) in 5 mL of DMF aqueous solution, and then 0.027 g of azobenzene- 3,3-dicarboxylic acid (referred to as H 2 azdc) and 0.004g NaOH in 5mL DMF solution were added to the above mixed solution, after about 20min of reaction, after standing and filtering, the solid phase was taken, which was the target framework coordination polymer.

Embodiment 2

[0021] Preparation of the target framework coordination polymer: at room temperature, first mix 0.046g CoCl 2 ·6H 2 O in 8 mL of deionized water was added to 0.048 gbbtz in 8 mL of DMF in water, and then 0.054 g of H 2 Azdc and 0.008g NaOH in 8mL DMF solution were added to the above mixed solution, after about 20 minutes of reaction, after standing and filtering, the solid phase was taken, which was the target framework coordination polymer.

Embodiment 3

[0023] Preparation of the target framework coordination polymer: at room temperature, first mix 0.069g CoCl 2 ·6H 2 O in 12 mL of deionized water was added to 0.072 gbbtz in 13 mL of DMF in water, and then 0.080 g of H 2 Azdc and 0.012g NaOH in 13mL DMF solution were added to the above mixed solution, after about 20 minutes of reaction, after standing and filtering, the solid phase was taken, which was the target framework coordination polymer.

[0024] 2. Product characteristics:

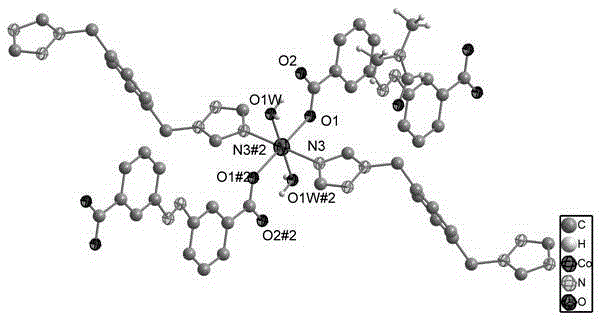

[0025] figure 1 It is a diagram of the coordination environment of the metal ion in the center of the complex. From figure 1 It can be seen that the central cobalt atom has 6 coordination atoms and is in a slightly distorted octahedral coordination environment.

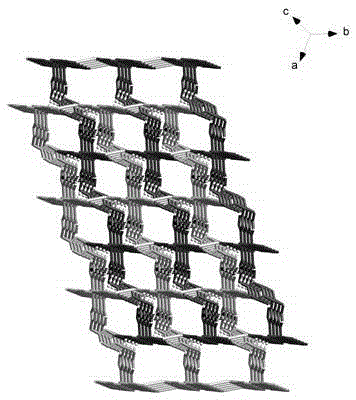

[0026] figure 2 It is the spatial packing diagram of the double interspersed three-dimensional supramolecular framework coordination polymer formed by the hydrogen bond effect obtained by adopting the method of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com