Synthesizing method of high-molecular-weight poly(butylene adipate-co-terephthalate)

A technology of butylene phthalate and polyadipic acid, which is applied in the field of synthesis of high molecular weight polybutylene terephthalate adipate, can solve the problem of low molecular quality, poor product performance, and mixed materials. Non-uniformity and other problems, to achieve uniform molecular chain structure, high elongation at break, and meet the needs of blown film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

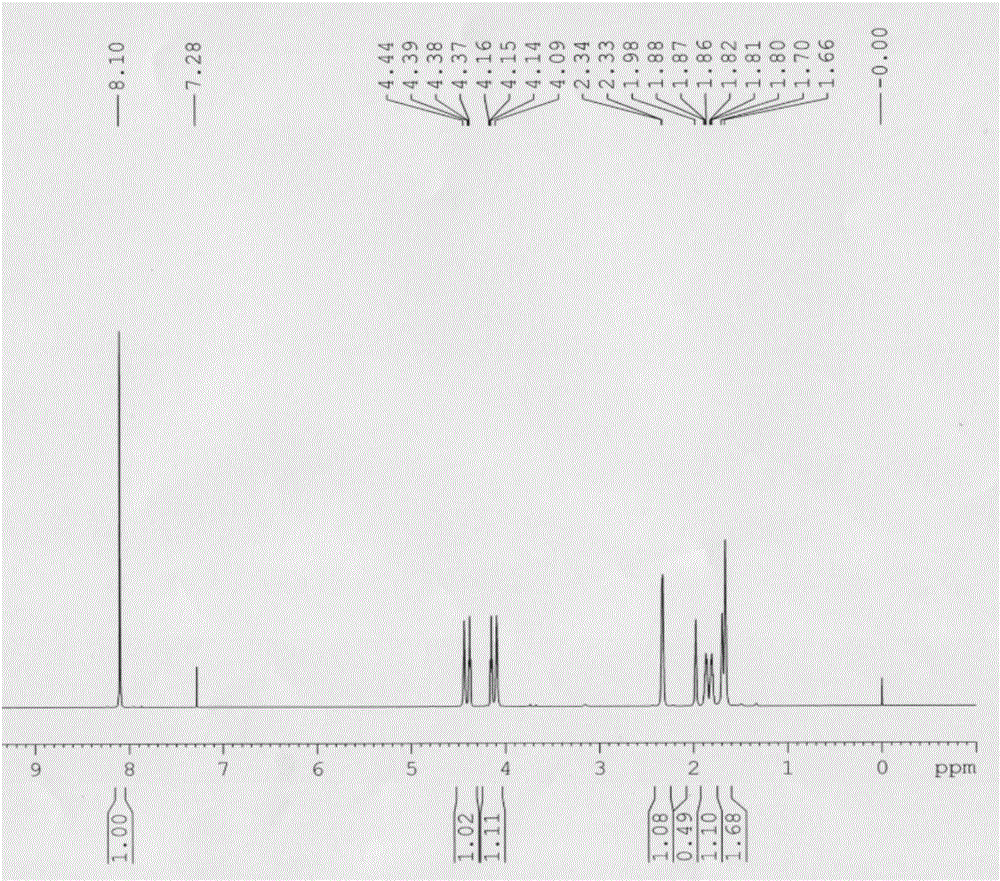

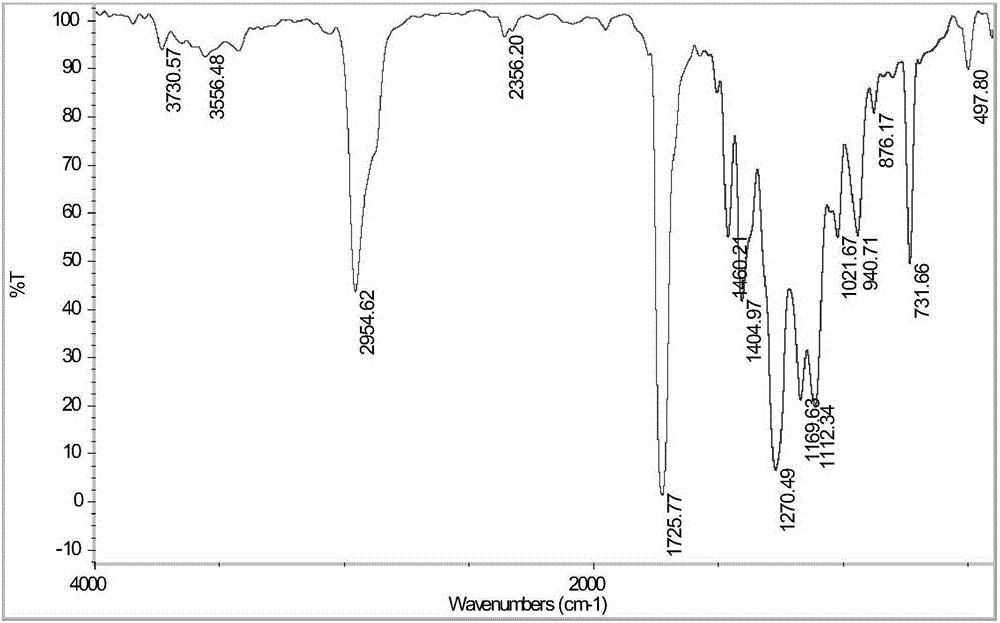

Image

Examples

Embodiment 1

[0020] Esterification stage: 1314g of adipic acid (AA) and 1050g of 1,4-butanediol (BDO) are added respectively in 10 liters of polycondensation reactors, start to heat slowly, after stirring, add sorbitol of 8g as The chain extender of this reaction, continue to heat up and keep at 150-160 ℃ to carry out normal pressure esterification dehydration reaction, react for 1.5 hours, the water yield reaches 80% of the theoretical value, and its acid value is measured at the same time. 7.8mg / g, that is is the end point of the reaction;

[0021] Secondary esterification stage: add the terephthalic acid (PTA) of 1494g and the 1,4-butanediol (BDO) of 1400g after esterification finishes, stir for a while, add 11.25g titanium-magnesium composite catalyst, and slowly be warming up to The normal dehydration reaction was carried out at 210°C for 2 hours, and the total amount of distilled by-products in the two stages of the reaction reached the sum of the theoretical amount of water and meth...

Embodiment 2

[0024] Esterification stage: Add 1314g of adipic acid (AA) and 920g of 1,4-butanediol (BDO) into a 10-liter polycondensation reactor respectively, start to heat slowly, and add 18g of glycerol after stirring evenly As a chain extender for this reaction, continue to heat up and keep it at 150-160°C for normal pressure esterification dehydration reaction, react for 2 hours, the water output reaches 80% of the theoretical value, and its acid value is measured at the same time. 5.3mg / g, is the end point of the reaction;

[0025] Transesterification stage: add dimethyl terephthalate (DMT) of 1746g and 1,4-butanediol (BDO) of 1400g after the esterification reaction finishes, stir for a while, add 0.38g tetra-n-butyl titanate, and Slowly raise the temperature to 210°C for normal dehydration reaction for 2.25 hours, the total amount of distilled by-products in the two stages of reaction reaches the total amount of theoretical water and methanol, which is the reaction end point of this...

Embodiment 3

[0028] Esterification stage: 1314g of adipic acid (AA) and 920g of 1,4-butanediol (BDO) were added respectively in 10 liters of polycondensation reactor, began to slowly heat, after stirring evenly, 15g of pentaerythritol was added as this The reaction chain extender, continue to heat up and keep at 150-160 ℃ to carry out normal pressure esterification dehydration reaction, react for 2.2 hours, the water yield reaches 80% of the theoretical value, and its acid value is measured at the same time 2.6mg / g, which is end point of reaction;

[0029] Transesterification stage: add dimethyl terephthalate (DMT) of 1746g and 1,4-butanediol (BDO) of 1400g after the esterification reaction finishes, stir for a while, add 0.38g tetra-n-butyl titanate, and Slowly raise the temperature to 210°C for normal dehydration reaction for 2.5 hours, the total amount of distilled by-products in the two stages of reaction reaches the total amount of theoretical water and methanol, which is the end poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com