Single crystal furnace having auxiliary material adding mechanism and application thereof

A single crystal furnace and auxiliary material technology, which is applied in the directions of single crystal growth, crystal growth, chemical instruments and methods, etc., can solve the problems of large variation in resistivity at the tail of the crystal ingot and inability to perform real-time control, and reduce the axial direction of the crystal ingot. The magnitude of resistivity fluctuation, the effect of providing quality and utilization, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

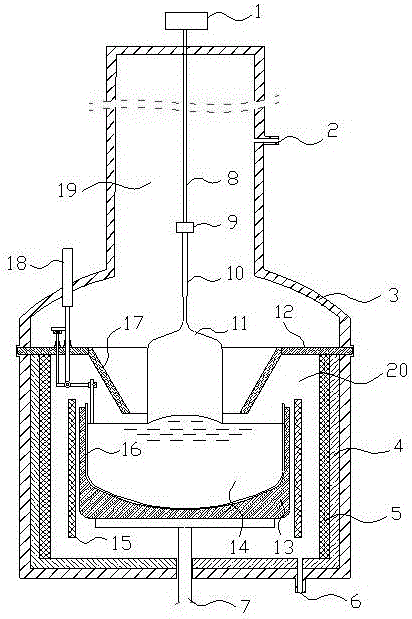

[0029] for the present invention figure 1 The shown single crystal furnace is combined with the auxiliary feeding structure described in the present invention to grow a high resistance N-type single crystal silicon ingot with low axial resistivity fluctuation.

[0030] The Cz method is used to grow 8 inches of N-type single crystal silicon in the direction. Firstly, the coefficient of the load cell is calibrated by the standard weight, so that the weighing deviation is less than 3%. Subsequently, 120 kg of phosphorus-doped polysilicon raw material was put into the quartz crucible at one time. Process a p-type single crystal silicon rod of ? 13 atoms / cm 3 ; At the same time, process a groove at the position of 20mm from the end of the P-type monocrystalline silicon rod, and fix it on the auxiliary material fixture with a bolt after cleaning. Subsequently, close the main chamber 4 and the auxiliary chamber 3, evacuate, vent argon, turn on the power supply of the main heater...

Embodiment 2

[0034] for the present invention figure 1 The shown single crystal furnace is combined with the auxiliary feeding structure described in the present invention to grow N-type single crystal silicon ingots for power devices with ultra-low resistivity and low axial resistivity fluctuation.

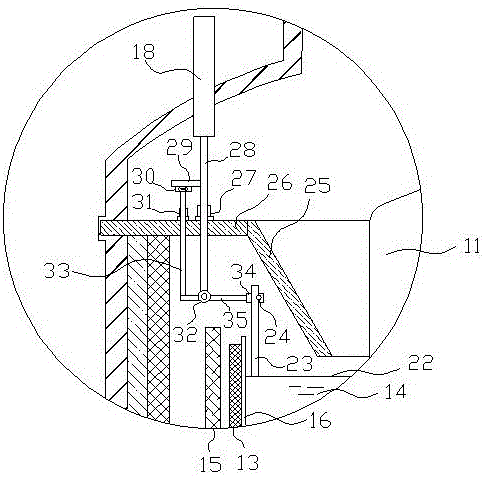

[0035] The Cz method is used to grow an 8-inch N-type monocrystalline silicon ingot with direction, and the target resistivity value is 60-100Ω. Firstly, the weighing coefficient of the load cell 30 is calibrated by the standard weight, so that the weighing deviation is less than 3%. Subsequently, 120 Kg of boron-doped polysilicon raw materials were put into the quartz crucible at one time. Process a ?20×200mm Si-Ga alloy rod, the mass ratio of Ga element in the alloy rod is 0.1%, and at the same time process a groove at the position of 20mm from the end of the Si-Ga alloy rod, through cleaning treatment Afterwards, it is fixed on the auxiliary material fixture 34 with a bolt. Subsequentl...

Embodiment 3

[0039] for the present invention figure 1 The single crystal furnace shown in the present invention, in combination with the auxiliary feeding structure described in the present invention, grows a high-resistance P-type monocrystalline silicon ingot for power devices with low axial resistivity fluctuations. Generally, the resistivity is not lower than 50Ω.cm, and the resistivity The change rate requirement is preferably not higher than 15%.

[0040] The CZ method is used to grow 8-inch P-type single crystal silicon rods in the direction. Firstly, the coefficient of the load cell is calibrated by the standard weight, so that the weighing deviation is less than 3%. Subsequently, 120Kg of boron-doped polysilicon raw materials were put into the quartz crucible at one time, and the initial concentration of boron was 1.78E14atoms / cm 3 . Process a Si-P alloy rod with a size of ?20×200mm. The mass ratio of phosphorus in the alloy rod is 0.1%. A groove is processed at a position 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com