Preparation method of water-resistant colloid and coated paper

A technology of hydrocolloid and starch, applied in the field of papermaking, can solve the problems such as the inability to meet the water resistance requirements of waterproof copper, and achieve the effect of improving the water resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

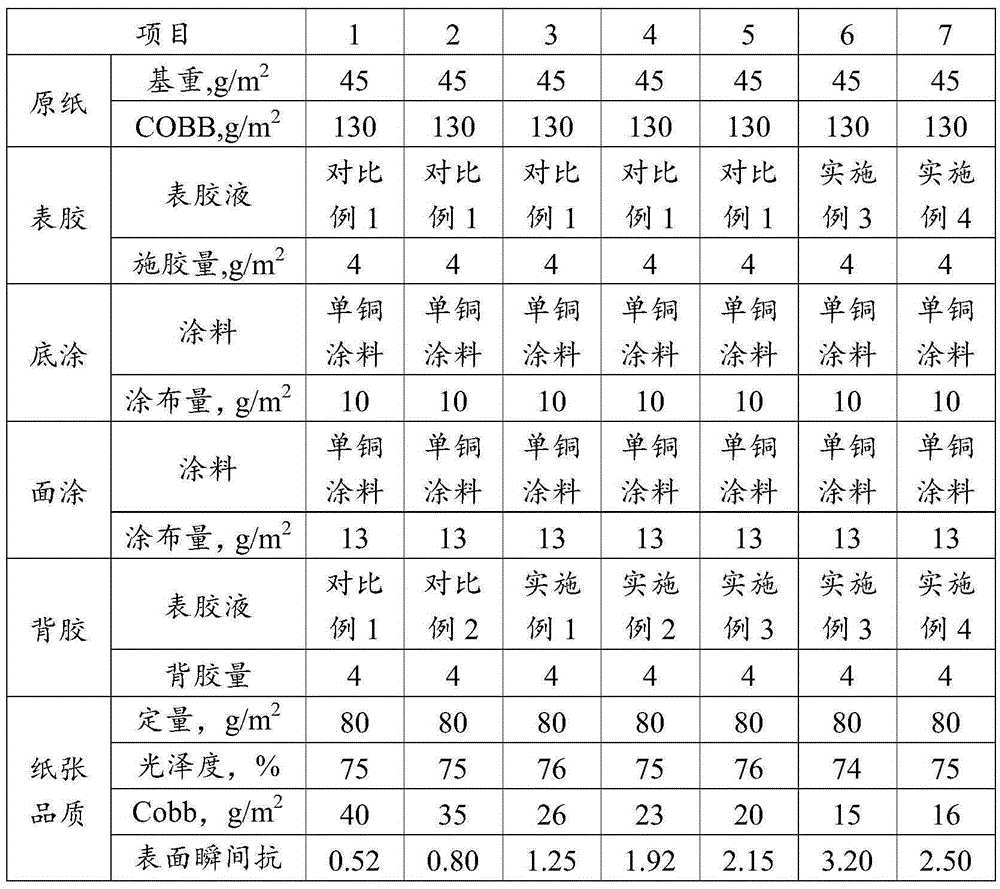

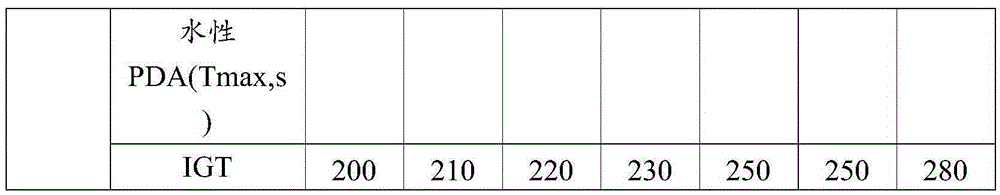

Examples

preparation example Construction

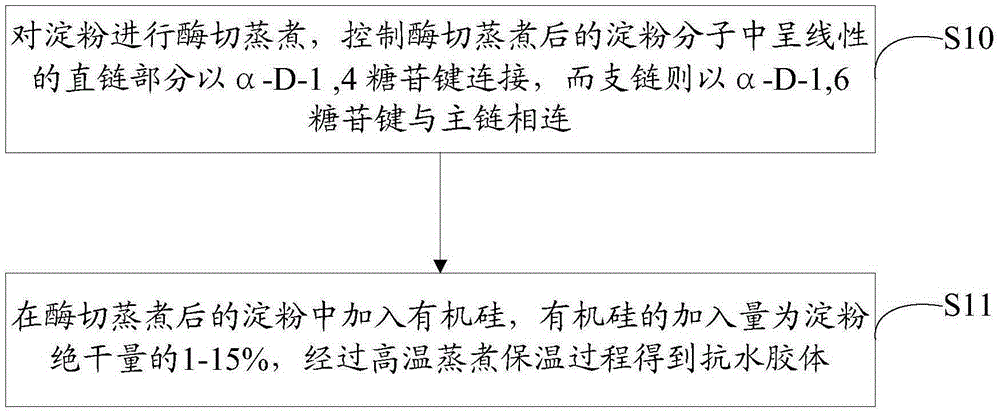

[0018] see figure 1 , figure 1 It is a flowchart of a preparation method of an anti-hydrocolloid provided in the embodiment of the present invention. As shown in the figure, the preparation method of the anti-hydrocolloid provided in the embodiment of the present invention includes:

[0019] S10: Carry out enzymatic digestion and cooking of starch, and control the linear part of the starch molecule after enzyme digestion and cooking to connect with α-D-1,4 glycosidic bonds, while the branched chains are connected with α-D-1,6 glycosidic bonds connected to the main chain.

[0020] The enzymatically digested and cooked starch described in the embodiments of the present invention refers to a high polymer polymerized by α-D-glucose.

[0021] In actual implementation, conventional starch raw materials can be selected, such as one or more combinations of raw tapioca starch, raw corn starch, and the like. Use high-temperature α-amylase and starch raw materials to mix and cook. Hi...

Embodiment 1

[0045] Starch: corn starch, 100 parts

[0046] Silicone: 3 parts

[0047] MFC: 0.7 parts

[0048] Surfactant: 0.4 parts

[0049] When raw corn starch is enzymatically digested and cooked, organic silicon is added, the cooking temperature is 120, and the temperature is kept at 90°C for 0.5h. During the heat preservation process, MFC and surfactant are added, stirred evenly, and sizing.

Embodiment 2

[0051] Starch: tapioca raw starch, 100 parts

[0052] Silicone: 5 parts

[0053] MFC: 1.2 parts

[0054] Surfactant: 1 part

[0055] When raw cassava starch is enzymatically cut and cooked, silicone is added, the cooking temperature is 130°C, and the temperature is kept at 90°C for 1 hour. During the heat preservation process, MFC and surfactant are added, stirred evenly, and sizing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com