Pentachlorophenol detection method

A pentachlorophenol and detection method technology, which is applied in the detection field of pentachlorophenol, can solve the problems of damaged instruments, polluted chromatographic columns, complicated environmental samples, etc., and achieves the effects of high detection sensitivity and shortened analysis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for detecting pentachlorophenol, the method comprising the following steps:

[0034] S1. Preparation of solid phase microextraction silk

[0035] (1) Cleaning of silver wire: Take a silver wire, cut the silver wire short, and cut it into a silver wire with a length of 5cm. First use acetone for ultrasonic cleaning, then ethanol for ultrasonic cleaning, and finally ultra-pure Ultrasonic cleaning with water;

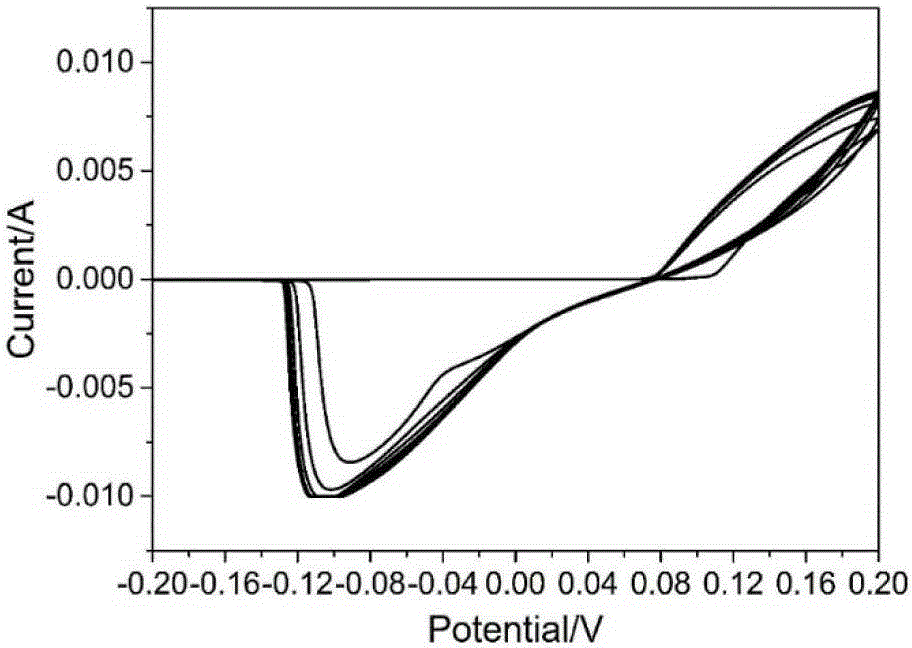

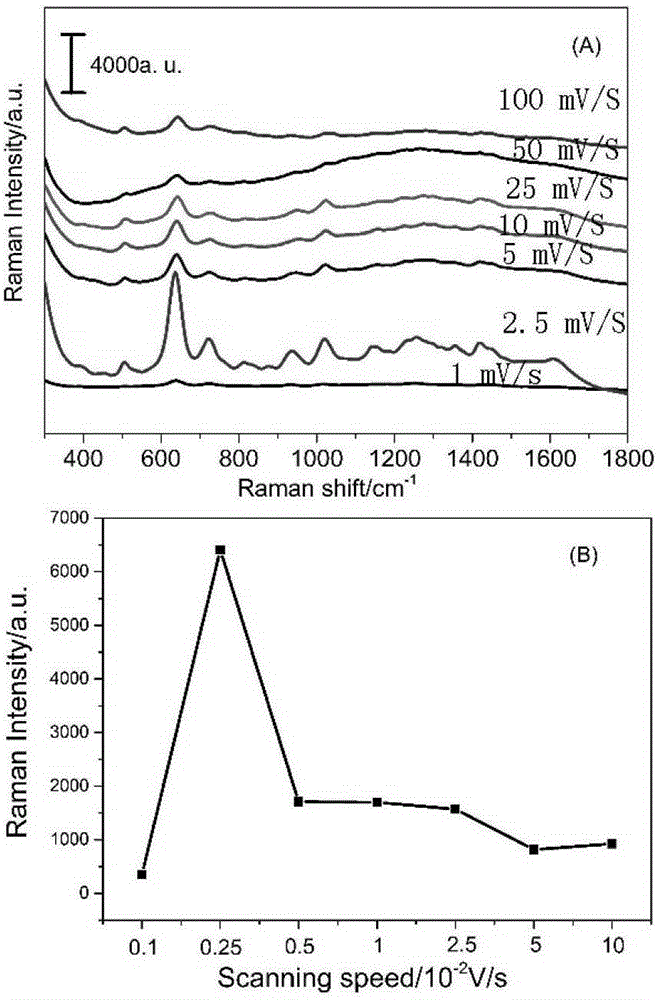

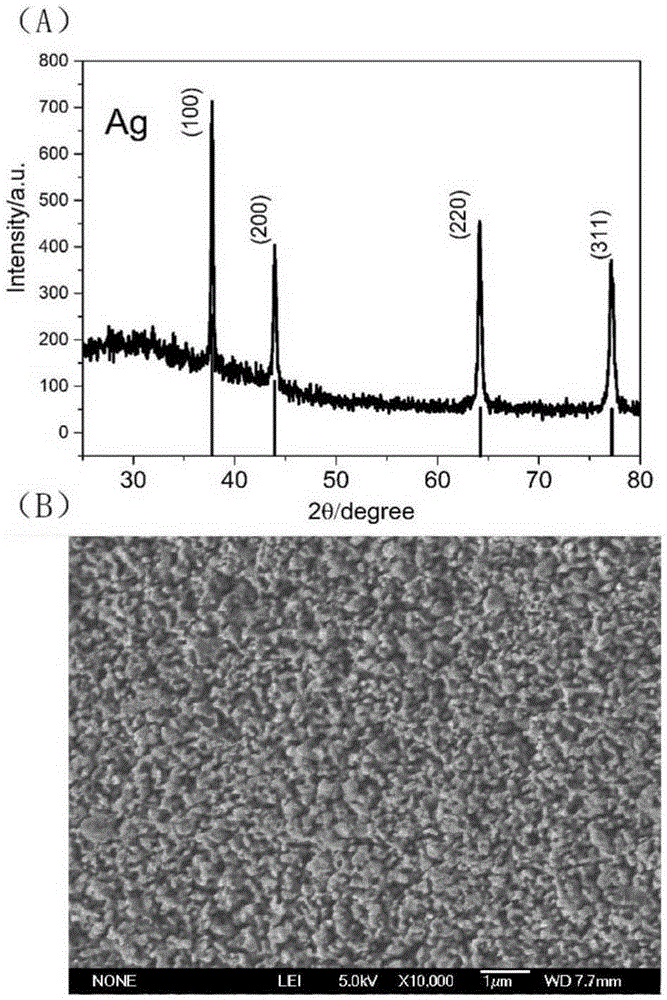

[0036] (2) Electrochemical roughening of silver wire: the electrochemical roughening method is used to form silver nanostructures on the surface of the cleaned silver wire. The steps are as follows: silver wire with a purity of 99.9% and a diameter of 0.40 mm is used as the working electrode , Ag / AgCl electrode as the reference electrode, 99.9% pure silver piece as the counter electrode, constitute a three-electrode system, 0.1M hydrochloric acid solution as electrolyte, scan rough by cyclic voltammetry at 2.5mV / s Make 20 turns of the silver wire, take out the r...

Embodiment 2

[0042] A method for detecting pentachlorophenol, the method comprising the following steps:

[0043] S1. Preparation of solid phase microextraction silk

[0044] (1) Cleaning of silver wire: Take a silver wire and cut the silver wire into a length of 10cm. First use acetone for ultrasonic cleaning, then ethanol for ultrasonic cleaning, and finally ultra-pure Ultrasonic cleaning with water;

[0045] (2) Electrochemical roughening of silver wire: The electrochemical roughening method is used to form silver nanostructures on the surface of the cleaned silver wire. The steps are as follows: silver wire with a purity of 99.9% and a diameter of 0.40 mm is used as the working electrode , Ag / AgCl electrode is used as the reference electrode, 99.9% pure silver piece is used as the counter electrode to form a three-electrode system, 0.1M hydrochloric acid solution is used as the electrolyte, and cyclic voltammetry is used to scan rough at 2.5mV / s scanning speed Make 20 turns of the silver wi...

Embodiment 3

[0051] A method for detecting pentachlorophenol, the method comprising the following steps:

[0052] S1. Preparation of solid phase microextraction silk

[0053] (1) Cleaning of silver wire: Take a silver wire, cut the silver wire short, and cut it into a silver wire with a length of 15cm. First use acetone for ultrasonic cleaning, then ethanol for ultrasonic cleaning, and finally ultra-pure Ultrasonic cleaning with water;

[0054] (2) Electrochemical roughening of silver wire: The electrochemical roughening method is used to form silver nanostructures on the surface of the cleaned silver wire. The steps are as follows: silver wire with a purity of 99.9% and a diameter of 0.40 mm is used as the working electrode , Ag / AgCl electrode is used as the reference electrode, 99.9% pure silver piece is used as the counter electrode to form a three-electrode system, 0.1M hydrochloric acid solution is used as the electrolyte, and cyclic voltammetry is used to scan rough at 2.5mV / s scanning spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com