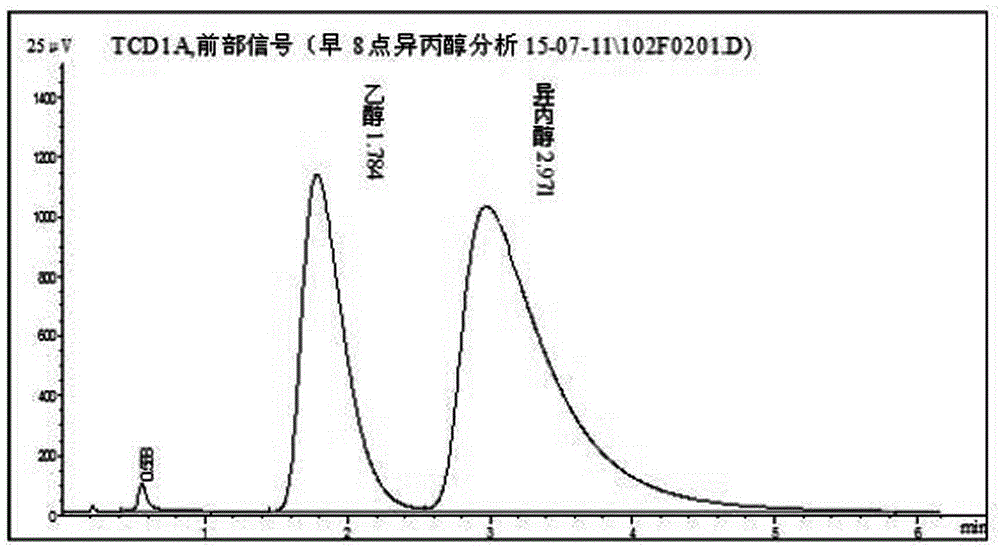

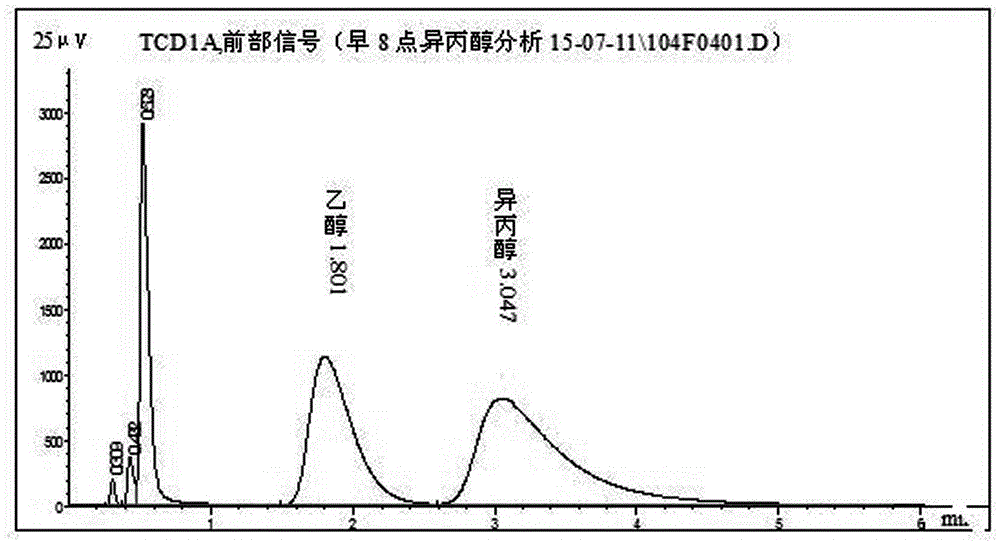

Method for determining content of isopropanol in urea dewaxing device

A technology of urea dewaxing and isopropanol, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of no clear national standards, inability to provide accurate data, and a large number of samples to be analyzed, so as to achieve effective and practical determination, reduce Analyze cost and analyze the effect of short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] First of all, the determination of sample collection and sampling points:

[0076] Starting at 0:00 every day, samples are collected and analyzed every 4 hours; in order to ensure the representativeness of the samples, all samples must be collected within 15 minutes, and samples are taken in 250ml glass sampling bottles. Such as Figure 8 The sampling locations for each sample shown are as follows:

[0077] Urine: Urine feed pump, pump outlet ( Figure 8 Urine sampling points in );

[0078] 96 Alcohol: 96 Alcohol Cooler, Heat Exchanger Outlet Guide ( Figure 8 96 alcohol sampling points in the middle);

[0079] 80 Alcohol: 80 Alcohol intermediate tank, pumping outlet to guide shower ( Figure 8 80 alcohol sampling points in);

[0080] Dilute alcohol water: Dilute alcohol water feed pump, outlet guide ( Figure 8 dilute alcohol water sampling point);

[0081] Dewaxed oil: dewaxed oil feed pump, outlet guide ( Figure 8 dewaxed oil sampling point in the sample); ...

example 2

[0110] Change the inlet temperature to 220°C, and other conditions are the same as Example 1, and the results are listed in the "Example Result Comparison Table".

example 3

[0112] Change the detector temperature to 300°C, and other conditions are the same as Example 1, and the results are listed in the "Example Result Comparison Table".

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com