PEDOT-ZnO ultraviolet light detector of flexible thin film type, and preparation method therefor

A flexible film and ultraviolet light technology, which is applied in semiconductor/solid-state device manufacturing, photovoltaic power generation, electric solid-state devices, etc., can solve problems such as inability to bend or fold, inconvenient installation and use, and achieve low cost, simple process, and excellent photosensitive properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step 1: Using the sol-gel method to prepare a doped ZnO material with zinc acetate, sodium nitrate and ammonium acetate as raw materials, the steps are as follows: configure 0.01mol / L zinc acetate, 0.001mol / L sodium nitrate and 0.01mol / L Ammonium acetate mixed solution, heated to 90 degrees Celsius, then added PVA to a concentration of 0.5g / L, stirred for 2 hours, then allowed to stand at room temperature and stirred for 1 hour to form a ZnO colloid. Put the colloid in a glass and put it in an oven to dry.

[0029] Step 2: put the dried ZnO into an atmosphere furnace, and perform heat treatment at 800°C in an atmosphere of oxygen and argon with a pressure ratio of 1:1. Then put ZnO into a ball mill, and use a ball mill with a vibration frequency of 1200 cycles / min to grind the heat-treated ZnO for 72 hours to obtain ZnO:(Na,N) powder with an average particle diameter of about 500 nm.

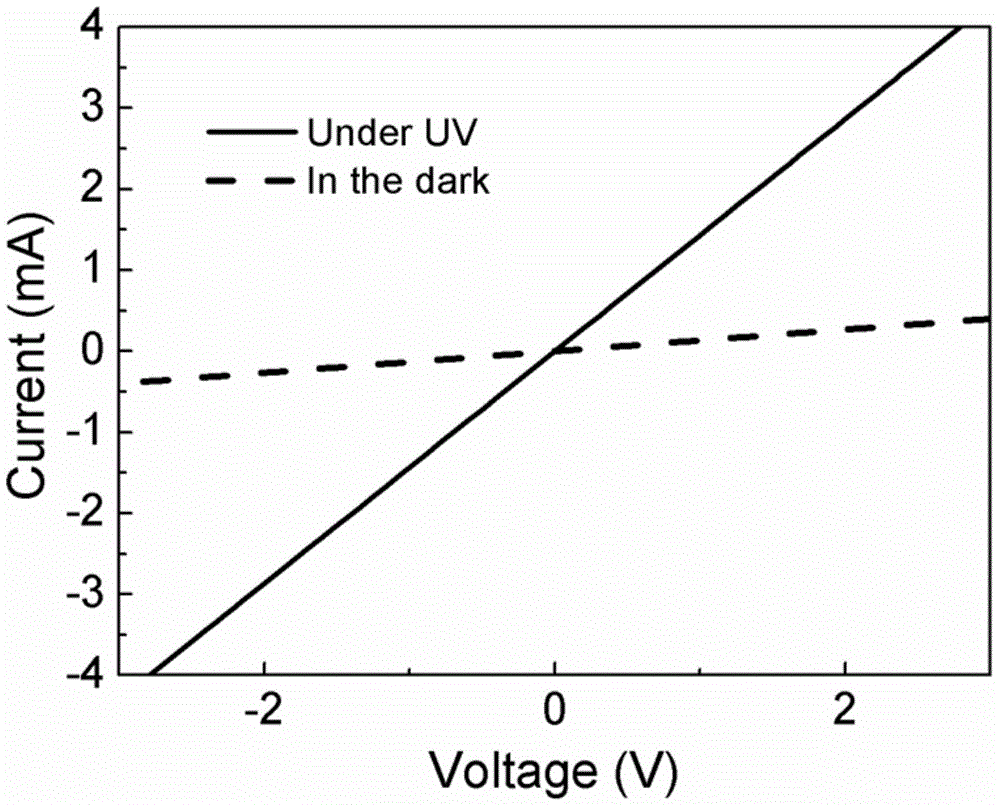

[0030] Step 3: Mix ZnO:(Na,N) powder with PEDOT:PSS (manufactured by Wuhan Sinuo Fuh...

Embodiment 2

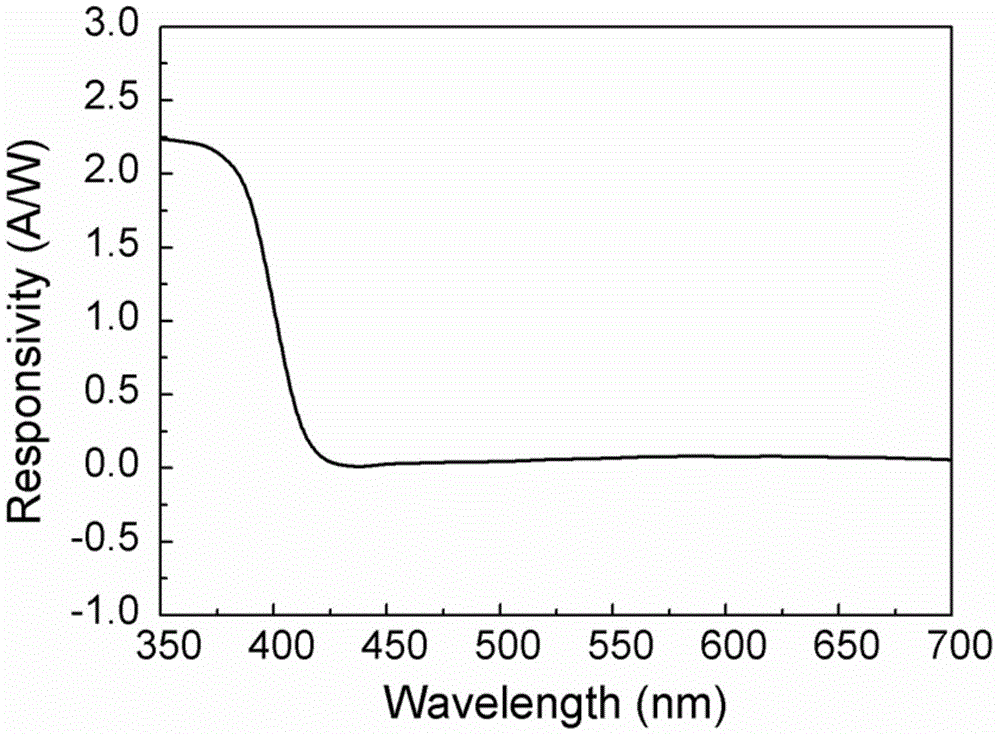

[0034] The preparation method and test are the same as in Example 1, but the concentration of the prepared solution in step 1 is changed to a mixed solution of 0.01 mol / L zinc acetate, 0.01 mol / L sodium nitrate, and 0.01 mol / L ammonium acetate. Table 1 shows the values of the responsivity of the ultraviolet light detector prepared in this real-time example. It can be seen from Table 1 that the response performance of the ultraviolet light detector in this embodiment is worse than that in Example 1.

Embodiment 3

[0036]The preparation method and test were the same as in Example 1, but the concentration of the solution prepared in step 1 was changed to a mixed solution of 0.01 mol / L zinc acetate, 0.001 mol / L sodium nitrate, and 0.1 mol / L ammonium acetate. Table 1 shows the values of the responsivity of the ultraviolet light detector prepared in this real-time example. It can be seen from Table 1 that the response performance of the ultraviolet light detector in this embodiment is worse than that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com