A kind of flexible film type pedot-zno ultraviolet light detector and preparation method thereof

A flexible film and ultraviolet light technology, which is applied in semiconductor/solid-state device manufacturing, photovoltaic power generation, electric solid-state devices, etc., can solve the problems of inconvenient installation and use, inability to bend or fold, and achieve low cost, simple process, and excellent photoconductivity. Effects of Response Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step 1: Using the sol-gel method to prepare a doped ZnO material with zinc acetate, sodium nitrate and ammonium acetate as raw materials, the steps are as follows: configure 0.01mol / L zinc acetate, 0.001mol / L sodium nitrate and 0.01mol / L Ammonium acetate mixed solution, heated to 90 degrees Celsius, then added PVA to a concentration of 0.5g / L, stirred for 2 hours, then allowed to stand at room temperature and stirred for 1 hour to form a ZnO colloid. Put the colloid in a glass and put it in an oven to dry.

[0029] Step 2: put the dried ZnO into an atmosphere furnace, and perform heat treatment at 800°C in an atmosphere of oxygen and argon with a pressure ratio of 1:1. Then put ZnO into a ball mill, and use a ball mill with a vibration frequency of 1200 cycles / min to grind the heat-treated ZnO for 72 hours to obtain ZnO:(Na,N) powder with an average particle diameter of about 500 nm.

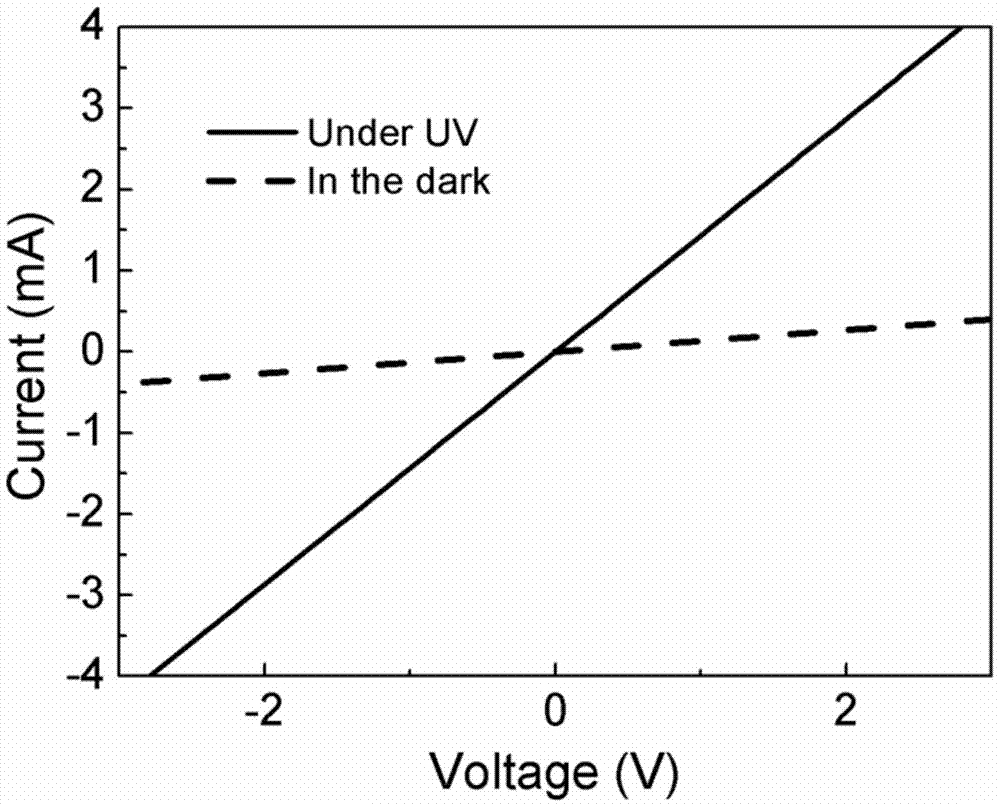

[0030] Step 3: Mix ZnO:(Na,N) powder with PEDOT:PSS (manufactured by Wuhan Sinuo Fuh...

Embodiment 2

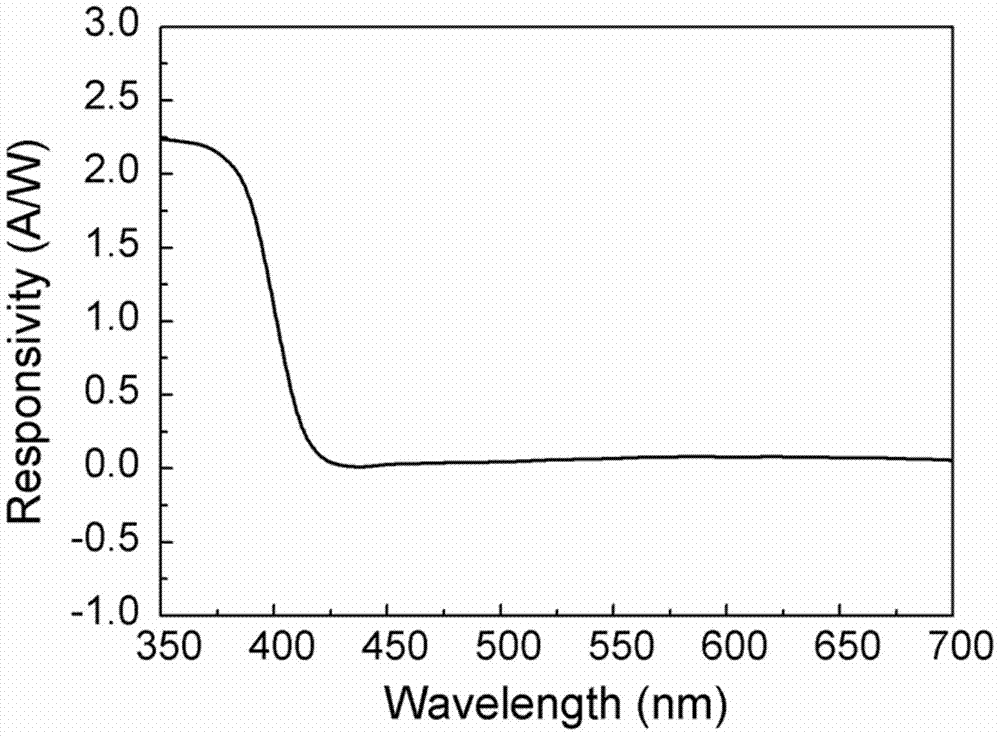

[0034] The preparation method and test are the same as in Example 1, but the concentration of the prepared solution in step 1 is changed to a mixed solution of 0.01 mol / L zinc acetate, 0.01 mol / L sodium nitrate, and 0.01 mol / L ammonium acetate. Table 1 shows the values of the responsivity of the ultraviolet light detector prepared in this real-time example. It can be seen from Table 1 that the response performance of the ultraviolet light detector in this embodiment is worse than that in Example 1.

Embodiment 3

[0036]The preparation method and test were the same as in Example 1, but the concentration of the solution prepared in step 1 was changed to a mixed solution of 0.01 mol / L zinc acetate, 0.001 mol / L sodium nitrate, and 0.1 mol / L ammonium acetate. Table 1 shows the values of the responsivity of the ultraviolet light detector prepared in this real-time example. It can be seen from Table 1 that the response performance of the ultraviolet light detector in this embodiment is worse than that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com