Black garlic capsule and preparation method thereof

A technology of black garlic and capsules, applied in food ingredients as anti-caking agents, food science, etc., can solve the problems of not being able to eat at any time, long time required, short storage time, etc., achieve good disintegration speed, improve efficiency, Good bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

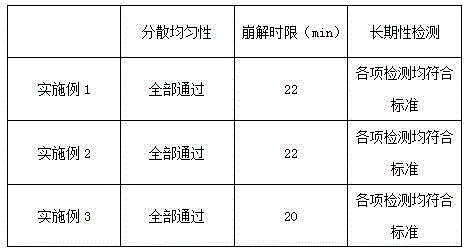

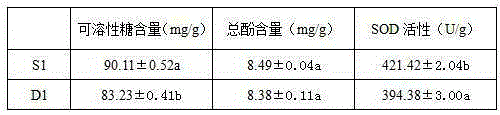

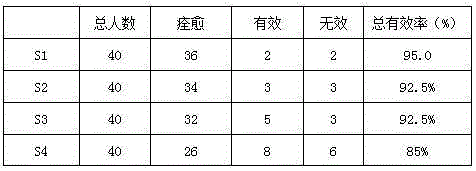

Examples

Embodiment 1

[0027] (1) After peeling and washing the garlic, cut it into garlic slices with a thickness of 2-4mm, then add papain, which accounts for 0.1% of the weight of the garlic, and hydrolyze it for 3 hours at 30°C, then raise the temperature to 80°C, and ferment for 3 days , and then fermented at 88°C for 9 days to obtain liquid fermented black garlic;

[0028] (2) Add the above-mentioned liquid fermented black garlic to 0.5% whey protein isolate by weight, stir evenly and then spray dry: the inlet temperature is 150°C, the outlet temperature is 70°C, and the feed rate is 50ml / min. The obtained particles are fermented black garlic. garlic powder;

[0029] (3) Add quantitative 75% ethanol to 12 parts of fungus powder and 2 parts of cornstarch, stir to disperse evenly, and obtain a mixed solution with a solid content of 90%;

[0030] (4) Mix 80 parts of fermented black garlic powder, 5 parts of tricalcium phosphate, 2 parts of microcrystalline cellulose, 3 parts of glyceryl monostea...

Embodiment 2

[0033] (1) After peeling and washing the garlic, cut it into garlic slices with a thickness of 2-4mm, then add papain, which accounts for 0.1% of the weight of the garlic, and hydrolyze it for 2.5 hours at 35°C, then raise the temperature to 83°C, and ferment for 3 days, and then fermented at 89°C for 8 days to obtain liquid fermented black garlic;

[0034] (2) Add the above-mentioned liquid fermented black garlic to 0.5% whey protein isolate by weight, stir evenly and then spray dry: the inlet temperature is 160°C, the outlet temperature is 80°C, and the feed rate is 50ml / min. The obtained particles are fermented black garlic. garlic powder;

[0035] (3) Add quantitative 75% ethanol to 15 parts of fungus powder and 2.5 parts of cornstarch, stir to disperse evenly, and obtain a mixed solution with a solid content of 85%;

[0036] (4) Mix 70 parts of fermented black garlic powder, 3 parts of tricalcium phosphate, 3 parts of microcrystalline cellulose, 3 parts of glyceryl monos...

Embodiment 3

[0039] (1) After peeling and washing the garlic, cut it into slices, then add papain, which accounts for 0.1% of the weight of the garlic, and hydrolyze it for 2 hours at 32°C, then raise the temperature to 85°C, ferment for 3 days, and then incubate at 90°C Next, ferment for 7 days to get liquid fermented black garlic;

[0040] (2) Add the above-mentioned liquid fermented black garlic to 0.5% whey protein isolate by weight, stir evenly and then spray dry: the inlet temperature is 155°C, the outlet temperature is 78°C, the feed rate is 50ml / min, and the obtained particles are fermented black garlic. garlic powder;

[0041] (3) Add quantitative 75% ethanol to 10 parts of fungus powder and 1.5 parts of cornstarch, stir to disperse evenly, and obtain a mixed solution with a solid content of 90%;

[0042] (4) Mix 76 parts of fermented black garlic powder, 4 parts of tricalcium phosphate, 3 parts of microcrystalline cellulose, 2 parts of glyceryl monostearate, and 1.5 parts of cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com