Porous carbon adsorbent as well as preparation method and application thereof

An adsorbent, porous carbon technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problems of high raw material price and complex preparation process, and achieve enhanced adsorption effect, low cost, high quality The effect of the adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Embodiment 1, the preparation of porous carbon adsorbent

[0060] Measure 1g of magnesium nitrate, add it to 20ml of water and stir to dissolve at room temperature (25°C) to obtain a transparent and clear aqueous solution of magnesium nitrate, then take 10g of cellulose powder (particle size: 5-10μm), and use mechanical stirring, while stirring Added to the above magnesium nitrate solution, as the cellulose absorbs water, the solution becomes viscous, the fluidity becomes poor, and the stirring becomes more difficult. After the cellulose is fully absorbed and impregnated, the cellulose slurry is obtained after uniform stirring for 12 hours. Then take the slurry and fill it up in a disc-shaped mold, fully dry it in an air-blast drying oven at 80 degrees Celsius (drying time is 12 hours), and form it. A disc-shaped cellulose mass was obtained. Next, the block is taken out, placed in a tube furnace with nitrogen gas, heated to 800 degrees Celsius at a heating rate of 5° / m...

Embodiment 2

[0065] Embodiment 2, the preparation of porous carbon adsorbent

[0066] Measure 5g of magnesium nitrate, add it to 20ml of water and stir to dissolve at room temperature (25°C) to obtain a transparent and clear magnesium nitrate aqueous solution. Other experimental steps are the same as in Example 1 to obtain the porous carbon adsorbent of the present invention, which is named Mg-C-2 .

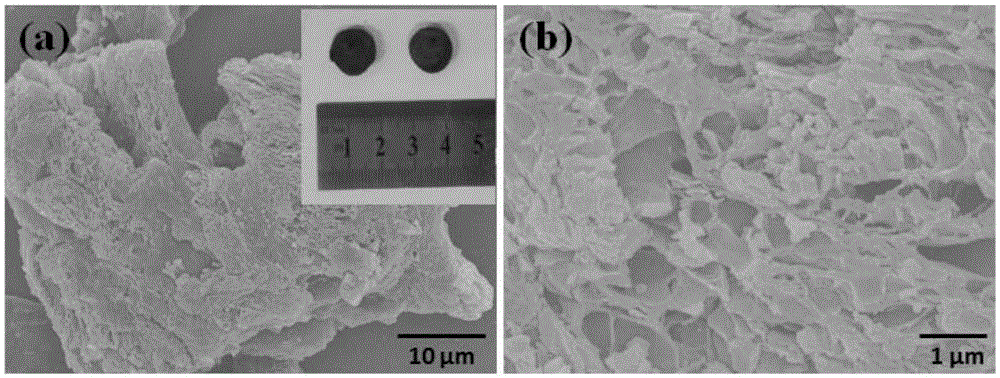

[0067] Characterization of the porous carbon adsorbent of the present invention: the surface morphology and pore structure of the porous carbon adsorbent after grinding and pulverization are observed under a scanning electron microscope, and the results are as follows: Figure 4 shown. Depend on Figure 4 (a) and Figure 4 (b) It can be seen that when the amount of magnesium nitrate is 5g, the pores of the prepared porous carbon adsorbent are more clearly visible, and the micron-sized macropores are all composed of stacked sheets, and these sheets are very thin, with a thickness of several...

Embodiment 3

[0070] Embodiment 3, the adsorption of porous carbon adsorbent to pentavalent arsenic

[0071] The arsenic source used in the experiment was Na 2 HASO 4 12H 2 O.

[0072] Take by weighing 10 mg of the porous carbon adsorbent obtained in Example 1 and Example 2 of the present invention respectively, then measure 25 ml of 10 ppm (mg / L) pentavalent arsenic solution, and vibrate at a constant temperature for 12 minutes in a shaker at 30 degrees Celsius and 300 revolutions. hours, filtered with a microporous membrane to obtain a clear solution, and analyzed the residual concentration of arsenic in the clear solution by an inductively coupled plasma-atomic emission spectrometer. As shown in Table 1, the content measurement results of the adsorption of arsenic ions in Examples 1 and 2 of the present invention are shown. Table 1 also shows the arsenic adsorption data of commercial activated carbon (AC) under the same conditions for comparison.

[0073] As can be seen from Table 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com