Preparation method of palladium-mesoporous silica core-shell nano-catalytic material

A mesoporous silica, core-shell nanotechnology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problems of tedious and time-consuming preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Weigh 0.1g of CTAB, add 50mL of deionized water and 0.5mL of 1M sodium hydroxide solution to fully dissolve the template agent CTAB in an alkaline aqueous system to obtain a uniform clear liquid;

[0022] (2) After stirring at 60°C for 30 minutes, add 1.25mL of 0.1M aqueous formaldehyde solution and 1.25mL of 0.05M sodium citrate aqueous solution, and then add 1.25mL of 0.1M sodium chloropalladate Na 2 PdCl 4 aqueous solution, so that formaldehyde and sodium citrate reduce sodium chloropalladate to palladium nanoparticles;

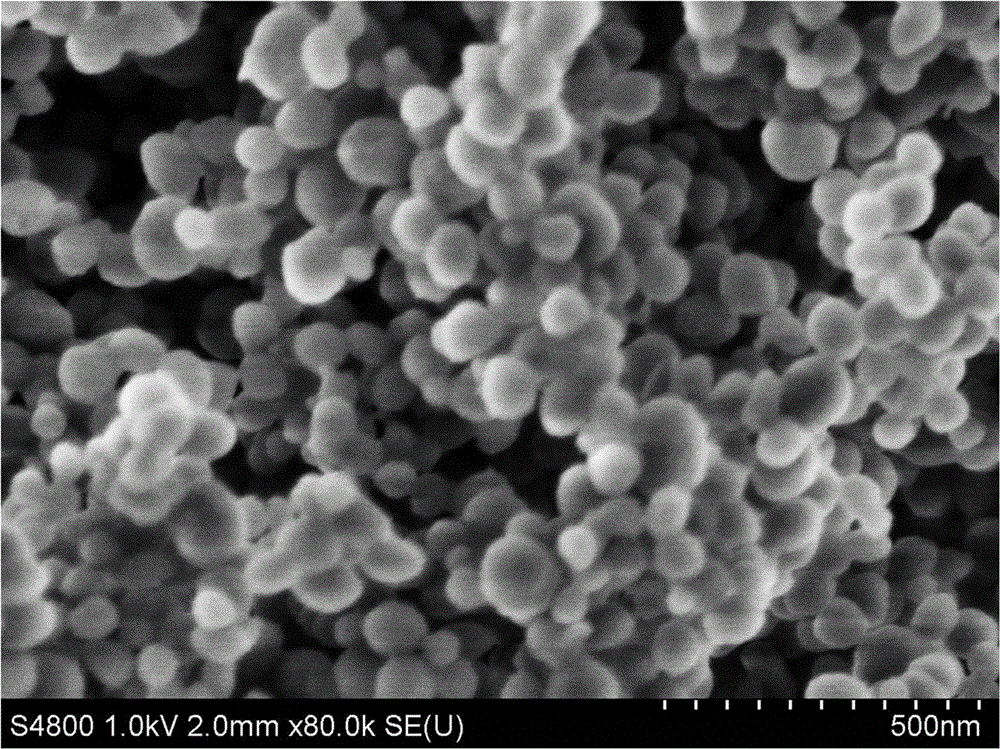

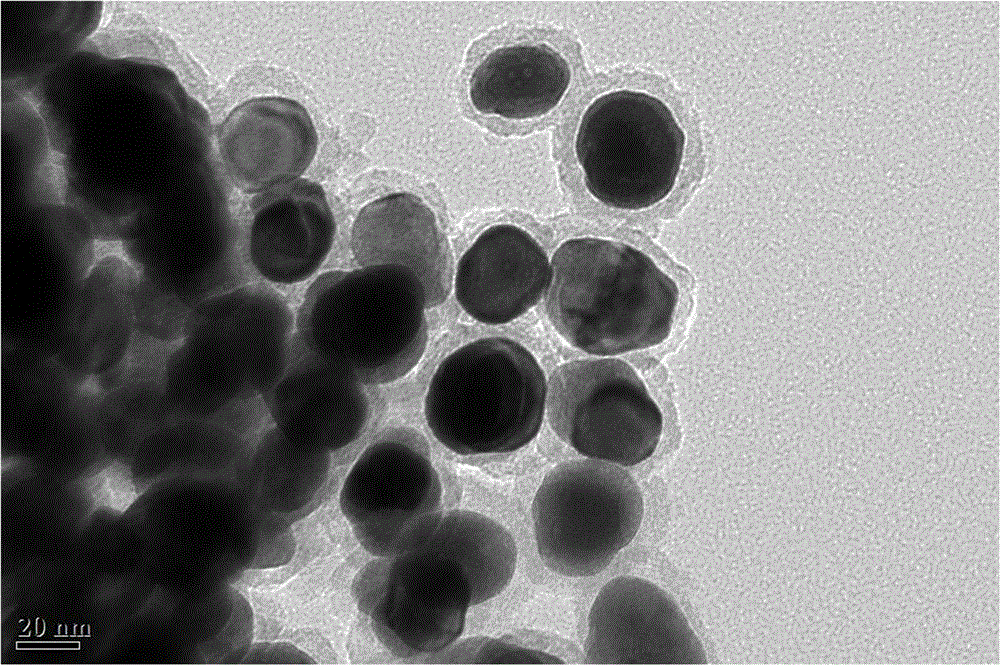

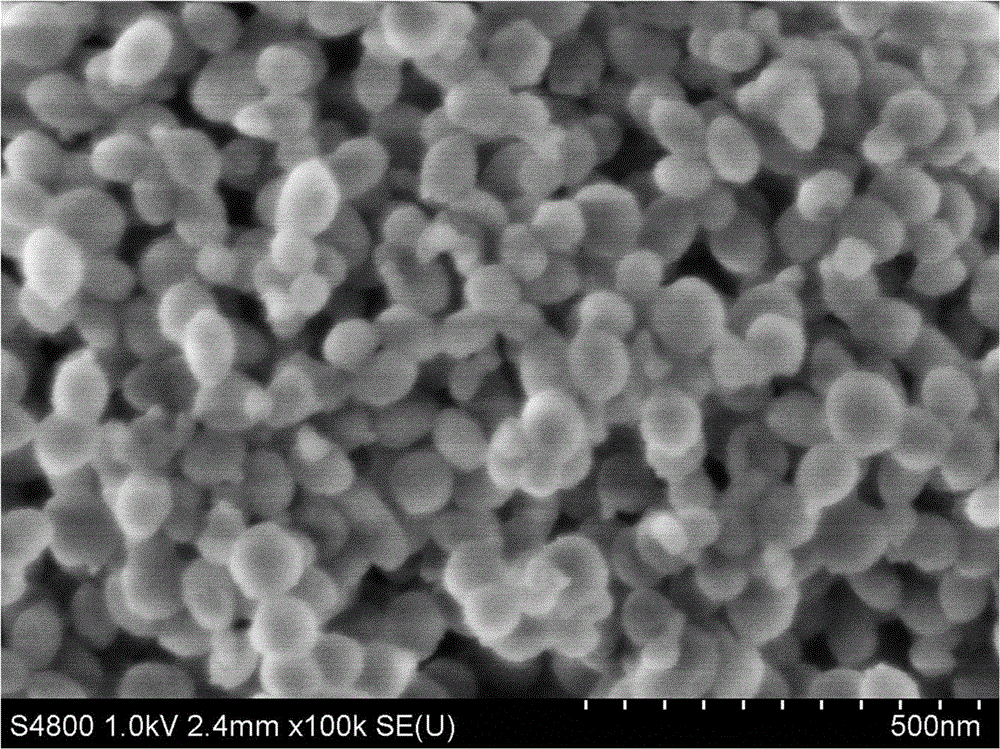

[0023] (3) After stirring for 15 minutes at 60°C, add a mixture of 0.5g tetraethyl orthosilicate and 1.5g ethanol, and continue stirring at 80°C for 2 hours to crosslink the tetraethyl orthosilicate and the surfactant CTAB micelles , the palladium core is coated with a mesoporous silica shell. The resulting precipitate was centrifuged, washed three times with water, then washed twice with ethanol, dried in an oven at 50°C overnight, and baked ...

Embodiment 2

[0025] (1) Weigh 0.075g of CTAB, add 50mL of deionized water and 0.4mL of 1M sodium hydroxide solution to fully dissolve the template agent CTAB in an alkaline aqueous system to obtain a uniform clear liquid;

[0026] (2) After stirring at 60°C for 30 minutes, add 0.375mL of 0.1M formaldehyde aqueous solution and 1.5mL of 0.05M sodium citrate aqueous solution, and then add 0.75mL of 0.1M palladium chloride PdCl 2 Aqueous solution, make formaldehyde and sodium citrate reduce palladium chloride into palladium nanoparticles;

[0027] (3) After stirring for 15 minutes at 60°C, add a mixture of 0.6g tetraethyl orthosilicate and 1.5g ethanol, and continue stirring at 80°C for 2 hours to crosslink the tetraethyl orthosilicate and the surfactant CTAB micelles , the palladium core is coated with a mesoporous silica shell. The resulting precipitate was centrifuged, washed three times with water, then washed twice with ethanol, dried overnight at 50°C in an oven, and baked in a muffle f...

Embodiment 3

[0029] (1) Weigh 0.125g of CTAB, add 50mL of deionized water and 0.6mL of 1M sodium hydroxide solution to fully dissolve the template agent CTAB in an alkaline aqueous system to obtain a uniform clear liquid;

[0030] (2) After stirring at 60°C for 30 minutes, add 0.75mL of 0.1M aqueous formaldehyde solution and 1.5mL of 0.05M sodium citrate aqueous solution, and then add 1.0mL of 0.1M sodium chloropalladate Na 2 PdCl 4 aqueous solution, so that formaldehyde and sodium citrate reduce sodium chloropalladate to palladium nanoparticles;

[0031] (3) After stirring for 15 minutes at 60°C, add a mixture of 0.4g tetraethyl orthosilicate and 1.5g ethanol, and continue stirring at 80°C for 2 hours to crosslink the tetraethyl orthosilicate and the surfactant CTAB micelles , the palladium core is coated with a mesoporous silica shell. The resulting precipitate was centrifuged, washed three times with water, then washed twice with ethanol, dried overnight at 50°C in an oven, and baked ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com