Manufacturing method for nanoscale zero-valent iron

A nano-zero-valent iron, a preparation process technology, applied in the field of environmental pollution control and chemical synthesis, can solve the problems of difficult control, small particle size of zero-valent iron, and reduced reactivity, so as to facilitate sampling analysis, convenient access, and avoid Effects of reduced or lost activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

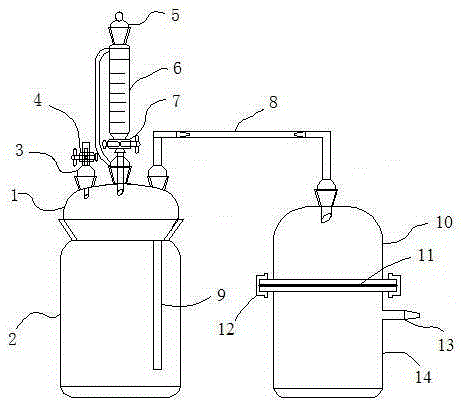

[0013] like figure 1 As shown, place the device on a magnetic stirrer, open the sealed cover, and mix 0.7993g FeSO 4 ·7H 2 0. 40mL distilled water and 0.05g polyethylene glycol are added into the reaction chamber, then the sealing cover is sealed with the reaction chamber through the frosted surface interface, the air inlet device is installed, that is, the gas pipeline interface, and the gas pipeline interface is connected with the nitrogen cylinder, and opened The gas flow control valve continuously feeds nitrogen gas, which is discharged through the exhaust device to replace the air in the reaction chamber. Under vigorous stirring, dilute HNO was added dropwise through the constant pressure separatory funnel 3 0.1mol / L NaBH with pH=3 4 The solution is 200mL, the drop rate of the reaction solution is controlled by the flow control valve of the constant pressure separatory funnel, and the chemical synthesis reaction of nanometer zero-valent iron is carried out in the react...

Embodiment 2

[0015] like figure 1 As shown, place the device on a magnetic stirrer, open the sealed cover, and mix 0.7993g FeSO 4 ·7H 2 0. 40mL of distilled water, 1.0g of molecular sieve and 0.05g of polyethylene glycol are added into the reaction chamber, then the sealing cover is sealed with the reaction chamber through the frosted surface interface, the air inlet device is installed, that is, the gas pipeline interface, and the gas pipeline interface is connected to the nitrogen cylinder Connect, open the gas flow control valve, continuously feed in nitrogen, discharge it through the exhaust device, and replace the air in the reaction chamber. Under vigorous stirring, dilute HNO was added dropwise through the constant pressure separatory funnel 3 0.1mol / L NaBH with pH=3 4 The solution is 200mL, the drop rate of the reaction solution is controlled by the flow control valve of the constant pressure separatory funnel, and the chemical synthesis reaction of nanometer zero-valent iron is...

Embodiment 3

[0017] like figure 1 As shown, place the device on a magnetic stirrer, open the sealed cover, and mix 0.4996g FeSO 4 ·7H 2 0. 40mL distilled water and 0.05g polyethylene glycol are added into the reaction chamber, then the sealing cover is sealed with the reaction chamber through the frosted surface interface, then the air inlet device is installed, that is, the gas pipeline interface, and the gas pipeline interface is connected with the nitrogen cylinder, and opened The gas flow control valve continuously feeds nitrogen gas, which is discharged through the exhaust device to replace the air in the reaction chamber. Under vigorous stirring, dilute HNO was added dropwise through the constant pressure separatory funnel 3 0.1mol / L NaBH with pH=3 4 The solution is 200mL, the drop rate of the reaction solution is controlled by the flow control valve of the constant pressure separatory funnel, and the chemical synthesis reaction of nanometer zero-valent iron is carried out in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com